A Three-level Fault-tolerant Docking Mechanism Against In-Orbit Shock

A docking mechanism and docking slot technology, applied in the connection, the parts of the connection device, the coupling device, etc., can solve the problems of re-insertion, damage to the electrical connection under load, damage, etc., and achieve high docking accuracy and solve the bearing problem. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below with reference to the accompanying drawings.

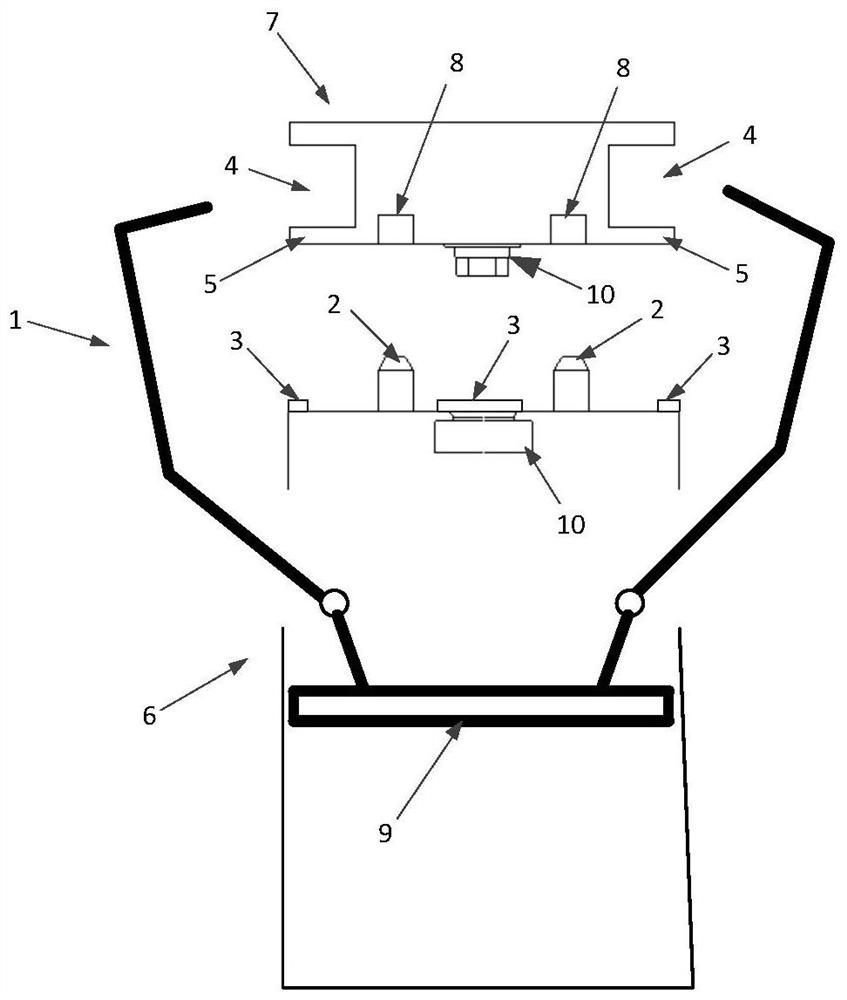

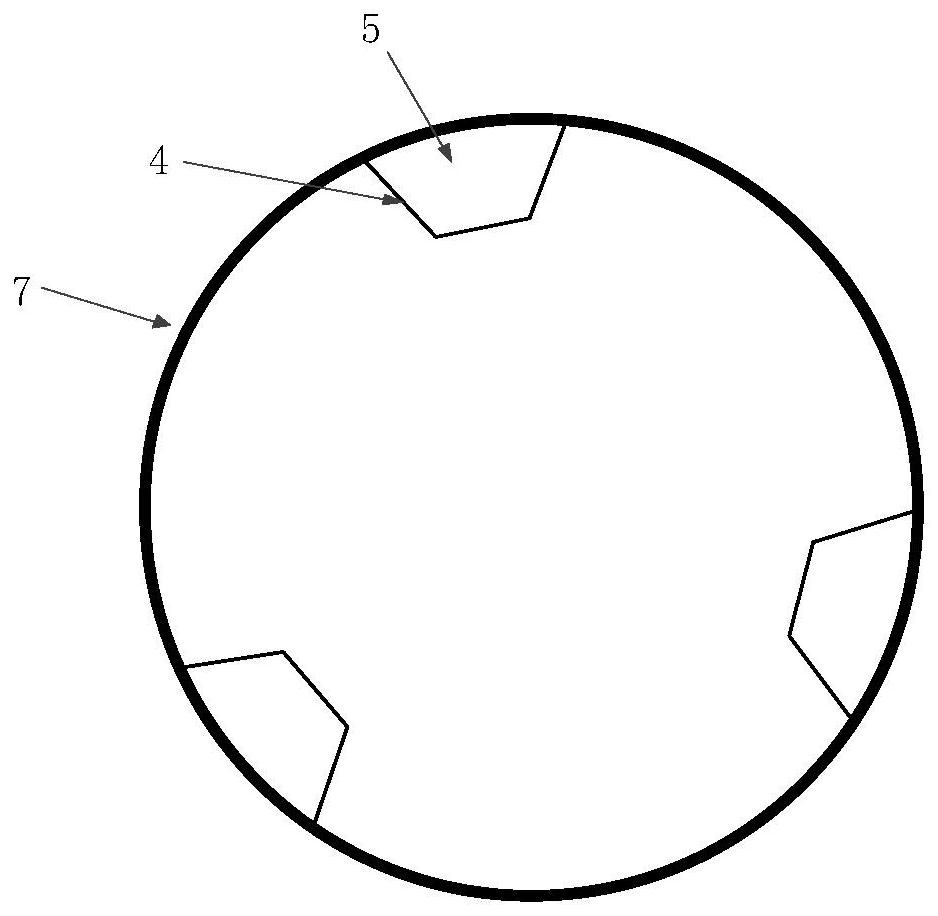

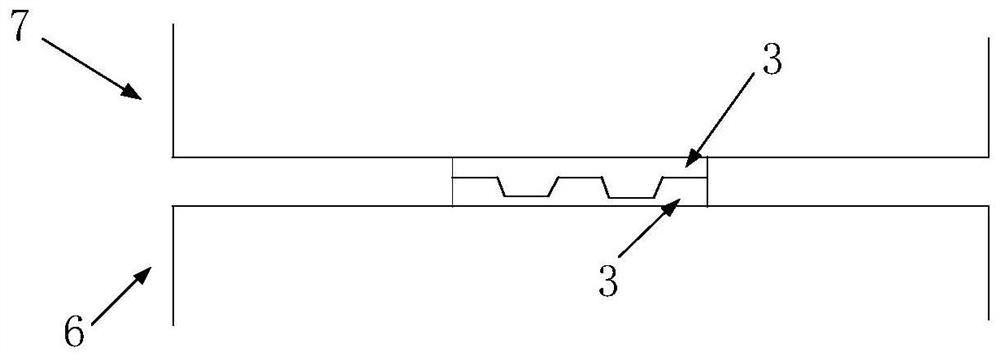

[0021] The three-stage fault-tolerant docking mechanism of the present invention has a three-stage fault tolerance of the rail impact, including the hand claw 1, the guide rod 2 and the pair block 3, such as figure 1 As shown; where the hand claw 1 is mounted at the active end 6, the active end 6 is mounted on the space tray. The pairing block 3 is mounted on the active end 6 and the passive end 7, the passive end 7 mounting the space tray, through the hand claw 1, the guide rod 2, the active end 6 and the passive end 7 docking process Capacity-based, realize the precision plugging of the active end pair and the passive electrical connector 10 on the surface of the electrical connector, and implements the impact resistance after the plug, the specific scheme is as follows:

[0022] The hand claws 1 circumferentially, and the end is mounted on the lifting stage 9 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com