Nanoparticle-filled hollow carbon fiber composite material as well as preparation method and application thereof

A fiber composite material and hollow carbon fiber technology, which is applied in the field of materials, can solve the problems of unreasonable structural design and complicated preparation of porous carbon materials, and achieve the effects of improving electrochemical performance, strong chemical adsorption, and good electrical contact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

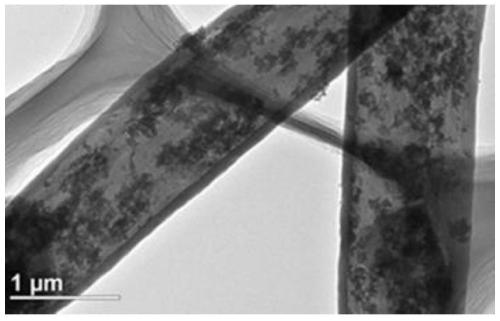

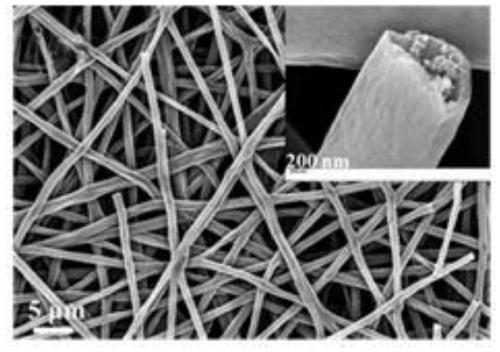

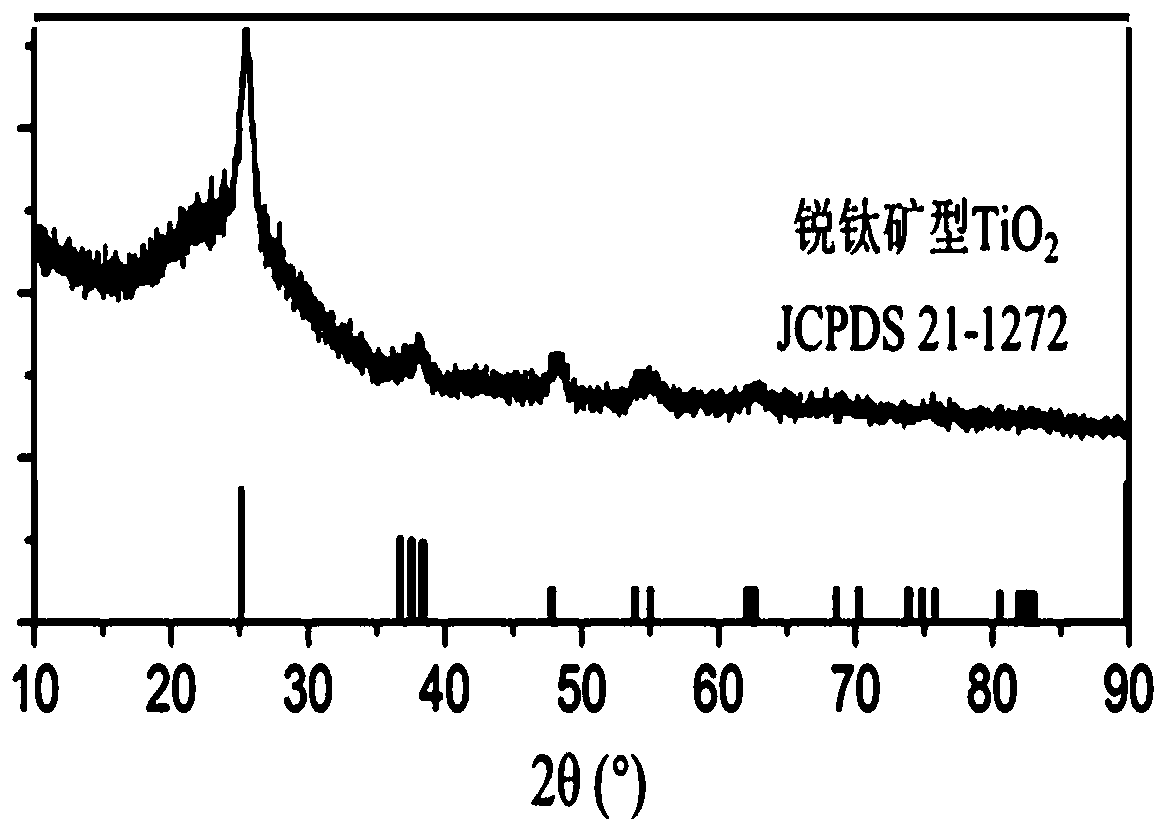

[0026] This embodiment provides a hollow carbon fiber composite material filled with nanoparticles, including hollow carbon fibers and nanoparticles filled in the hollow carbon fibers. The nanoparticles include any one or a combination of two or more of metal oxides, nitrides, and carbon nanoparticles; the diameter of the nanoparticles is less than 200nm.

Embodiment 2

[0028] This embodiment provides a method for preparing a hollow carbon fiber composite material, comprising the following steps:

[0029] Step 1. Two spinning solutions, solution A and solution B, are prepared, the carbonization yield of solution A is greater than that of solution B, and the nanoparticles are dispersed in solution B;

[0030] Step 2, using solution A and solution B dispersed with nanoparticles as shell solution and core solution respectively, and using coaxial electrospinning technology to prepare composite fibers with core-shell structure;

[0031] Step 3: Oxidize and carbonize the composite fiber with a core-shell structure prepared in Step 2 to form a hollow carbon fiber composite material filled with nanoparticles.

[0032] Further, the solvent of solution A and solution B is N,N-dimethylformamide, the mass percentage concentration of solution A is 5%-15%, and the mass percentage concentration of solution B is 8% of the mass percentage concentration of sol...

Embodiment 3

[0038] This embodiment provides an application method of hollow carbon fiber composite material filled with nanoparticles in energy storage, including using the hollow carbon fiber composite material as a sulfur carrier, assembling and testing a lithium-sulfur battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com