Three-dimensional bag template device

A three-dimensional bag and template technology, which is used in textiles and papermaking, cloth feeding mechanisms, sewing equipment, etc., can solve the problems of asymmetric sticking bags on the left and right sides, the three-dimensional strips are easy to be buttoned and uneven, and there are many operating procedures, so as to save production time. , the operation is simple, the effect of reducing the difficulty coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

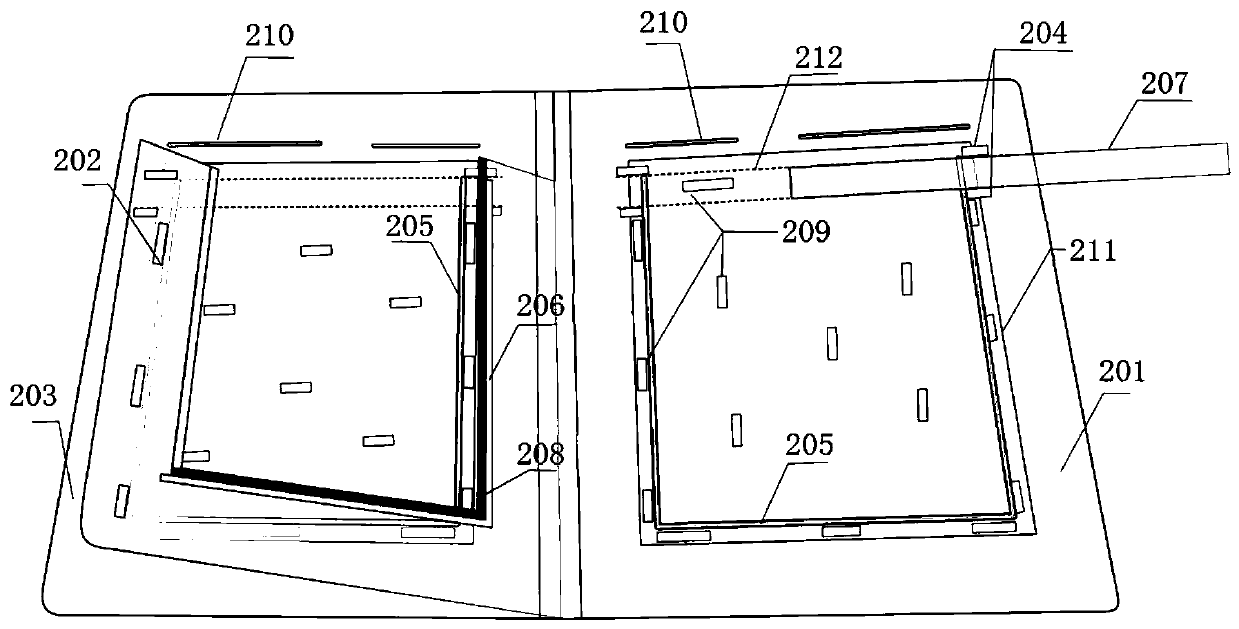

[0026] A kind of three-dimensional bag formwork device, its structure sees figure 1 As shown, it includes bottom board 201, middle board 202 and top board 203 which can be stacked sequentially from top to bottom, and when the bottom board 201, middle board 202 and top board 203 are stacked, the three have a vertical through U-shaped three-dimensional bag hidden line slot 205, the bottom plate 201 is horizontally arranged with a positioning groove at the opening position of the three-dimensional bag hidden line slot 205, and a plastic rubber sheet 207 that compresses the three-dimensional bag cutting pieces can be placed in the positioning groove, and the middle laminate The middle position and the top of 202 are hollowed out, and form a U-shaped groove that just lets out the hidden line groove position 205 of the three-dimensional bag.

[0027] see you again figure 1 As shown, the inner edge of the U-shaped groove of the middle laminate 202 is installed with an adhesive strip...

Embodiment 2

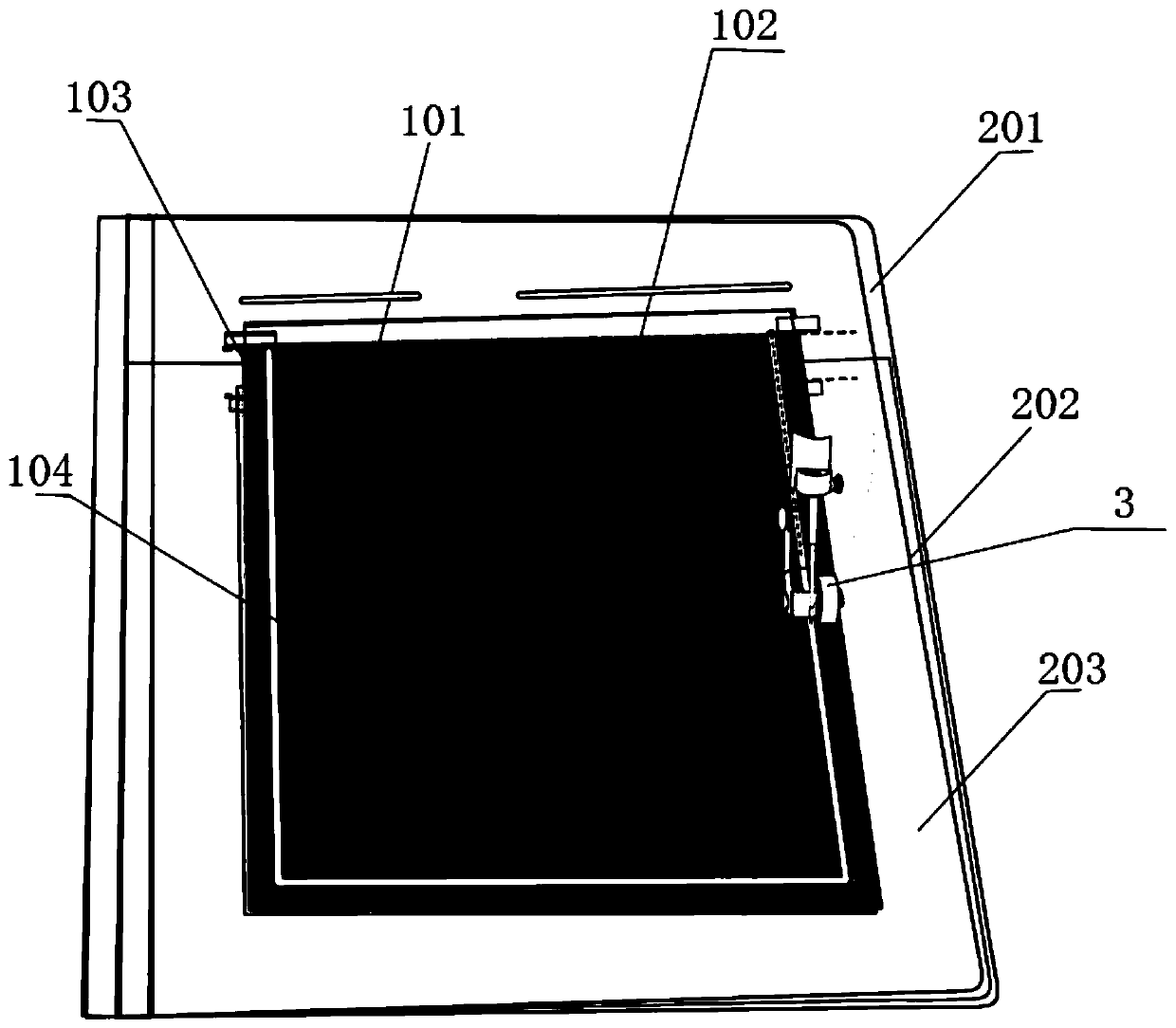

[0040] This embodiment provides a process for making three-dimensional bags with a flat car, specifically refer to Figure 4 As shown, it sequentially carries out the processes of patch pocket surface layer cut piece 103 and bag bottom layer cut piece 101, folding and ironing the bag opening, placing three-dimensional strip cut piece 104 and sewing, patch pocket inner layer cut piece 102, and sewing the three layers together .

[0041] By comparing the production of three-dimensional bags in Example 1 and Example 2, it can be clearly seen that the conventional flat car production process in Example 2 is complex in operation, with many procedures and prone to three-dimensional strips, easy to buckle and uneven, and easy to cause deformation of the three-dimensional bag. Patch pockets on the left and right sides are asymmetrical. After adopting the template device of Embodiment 1, the production can be completed by one-time sewing by simply arranging each cut piece, which is ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com