Horizontal axial perforating or grooving device for long-axis ceramic pipe and use method thereof

A ceramic tube and long shaft technology is applied in the field of axial drilling or slotting devices for horizontal long shaft ceramic tubes, which can solve the problems of high work intensity, high operating platform height, and easy deviation, so as to reduce work difficulty and The effect of risk factor, improving work efficiency and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

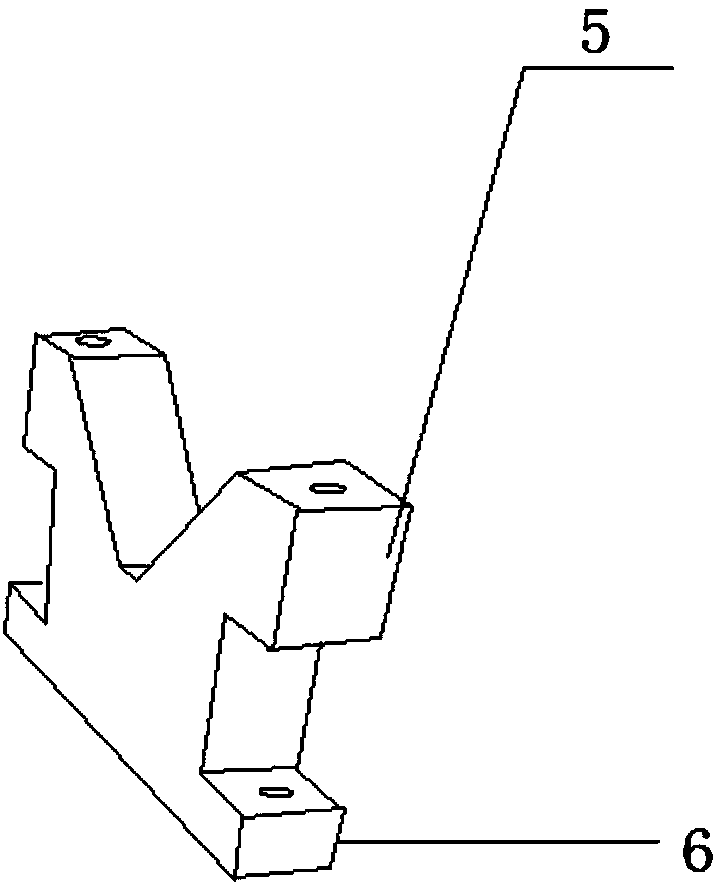

[0036] This embodiment provides a horizontal long-axis ceramic tube axial punching or slotting device, such as Figure 1-2 , 4-7, which include:

[0037] Fixing mechanism, drilling or grooving mechanism, limit mechanism, axial movement mechanism, limit crawler and crawler groove for limit crawler 2 walking, fixing mechanism, drilling or grooving mechanism of long-axis ceramic tube 1 , the limit mechanism and the axial movement mechanism are all mounted on the frame, the limit crawler is connected with the axial movement mechanism, and the movement range of the axial movement mechanism is limited by the limit crawler 2 .

[0038] The drilling or grooving mechanism and the limit mechanism are located between the fixed mechanism and the axial movement mechanism. The drilling or grooving mechanism passes through the limit mechanism and is driven by the axial movement mechanism along the axial direction of the long-axis ceramic tube 1. move.

[0039]The fixing mechanism includes ...

Embodiment 2

[0054] The features of this embodiment that are the same as those of Embodiment 1 will not be described in detail. The features of this embodiment that are different from Embodiment 1 are:

[0055] The drilling or grooving mechanism includes 3 drill assemblies and the drive assembly of the drill assembly. The drill assembly passes through the corresponding limit mechanism and rotates under the drive of the drive assembly. The drill assembly includes a drill and a drill rod 14. The drill and the drill The rod 14 is connected, and the drill bit is provided with a water outlet, and the water outlet is connected with a cold water pipe, and the temperature is lowered during the drilling or groove process.

[0056] The limit mechanism includes 3 limit assemblies that move along the periphery of the drill pipe. The limit assemblies are evenly distributed along the periphery of the drill pipe 14. The limit assemblies include a support seat 15 and a pulley 16. The pulley 16 is fixed to ...

Embodiment 3

[0059] The features of this embodiment that are the same as those of Embodiment 1 will not be described in detail. The features of this embodiment that are different from Embodiment 1 are:

[0060] The limit mechanism includes 4 limit assemblies that move along the periphery of the drill pipe, and the 4 limit assemblies are evenly distributed along the periphery of the drill pipe 14. The limit assemblies include a support seat 15 and a pulley 16, and the pulley 16 is fixed on the support seat 15 by bolts. In the lengthwise direction, the pulley 16 encloses a circular rotating space in which the drill pipe 14 rotates, and the support base 15 is inserted into the groove 18 of the ring-shaped fixed disk 17, and is fixed on the ring-shaped fixed disk 17 by bolts passing through the threaded holes of the ring-shaped fixed disk 17. On the fixed plate 17, the screw holes are opened in the width direction of the support base 15, and the bolts pass through the vertical plate 20 of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com