Soil conditioner based on kitchen waste, preparation method thereof and soil improvement method

A technology for soil conditioner and kitchen waste, which is applied in the field of waste treatment, can solve the problems of difficult disposal, pollution, and difficulty in utilization of kitchen waste, and achieves the effects of facilitating subsequent treatment, promoting anaerobic fermentation process, and reducing moisture content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

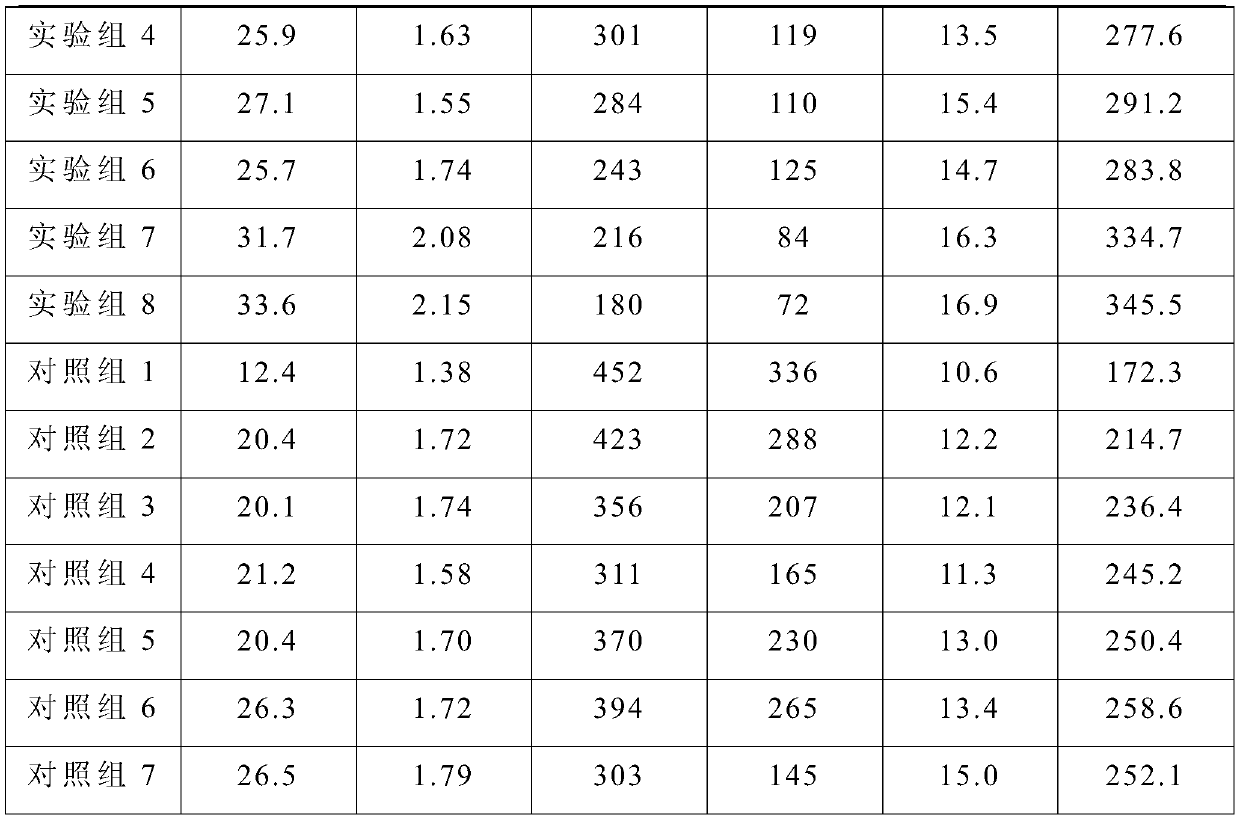

Examples

Embodiment 1

[0034] A preparation method of a soil conditioner based on kitchen waste, comprising the following steps:

[0035] (1) Raw material processing: the collected kitchen waste is sorted by a sorting machine to remove the undecomposed and unbreakable substances, and then crush the remaining organic matter to 40 mesh to obtain an organic mixture with uniform particle size;

[0036] (2) Water elution of salt: add water to the organic mixture obtained in step (1) at a mass ratio of 1:2, control the temperature at 60° C., and stir for 15 minutes to obtain a water-washed organic mixture;

[0037] (3) Centrifugal dehydration: the water-washed organic mixture obtained in step (2) is centrifuged for 10min dehydration at a rotating speed of 4000r / min, and the grease in the waste water is preliminarily filtered out to obtain a dehydrated organic mixture;

[0038] (4) secondary deoiling: in the dehydration organic mixture that step (3) obtains, add compound enzyme preparation, comprise the pe...

Embodiment 2

[0041] A preparation method of a soil conditioner based on kitchen waste, comprising the following steps:

[0042] (1) Raw material treatment: the collected food waste is sorted by a sorting machine to remove the undecomposed and unbreakable substances, and then crush the remaining organic matter to 60 mesh to obtain an organic mixture with uniform particle size;

[0043] (2) Water elution of salt: add water to the organic mixture obtained in step (1) at a mass ratio of 1:3, control the temperature at 50° C., and stir for 20 minutes to obtain a water-washed organic mixture;

[0044] (3) Centrifugal dehydration: the water-washed organic mixture obtained in step (2) is centrifuged for 8min dehydration at a rotating speed of 6000r / min, and the grease in the waste water is preliminarily filtered out to obtain a dehydrated organic mixture;

[0045] (4) secondary deoiling: in the dehydration organic mixture that step (3) obtains, add compound enzyme preparation, comprise the pectina...

Embodiment 3

[0048] A preparation method of a soil conditioner based on kitchen waste, comprising the following steps:

[0049] (1) Raw material treatment: the collected kitchen waste is sorted by a sorting machine to remove the undecomposed and unbreakable substances, and then crush the remaining organic matter to 80 mesh to obtain an organic mixture with uniform particle size;

[0050] (2) Water elution of salt: add water to the organic mixture obtained in step (1) at a mass ratio of 1:4, control the temperature at 70° C., and stir for 15 minutes to obtain a water-washed organic mixture;

[0051] (3) Centrifugal dehydration: the water-washed organic mixture obtained in step (2) is centrifuged for 6 minutes to dehydrate at a rotating speed of 8000r / min, and the grease in the waste water is preliminarily filtered out to obtain a dehydrated organic mixture;

[0052] (4) Secondary deoiling: in the dehydration organic mixture that step (3) obtains, add compound enzyme preparation, comprise th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com