A forming process for making aluminum products from aluminum plates

A technology for forming and processing aluminum products, which is applied in the field of forming and processing technology for making aluminum products from aluminum plates. It can solve problems such as low work efficiency, accumulation, and cuts, and achieve the effects of eliminating potential safety hazards, ensuring appearance quality, and reducing working hours.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

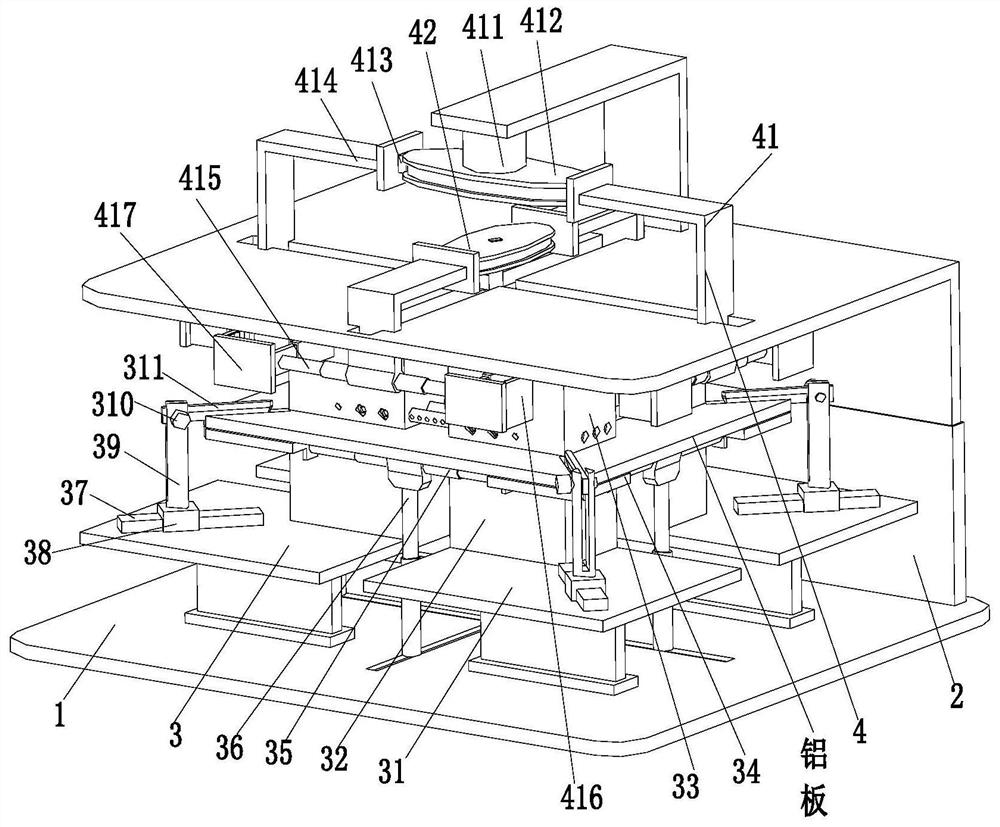

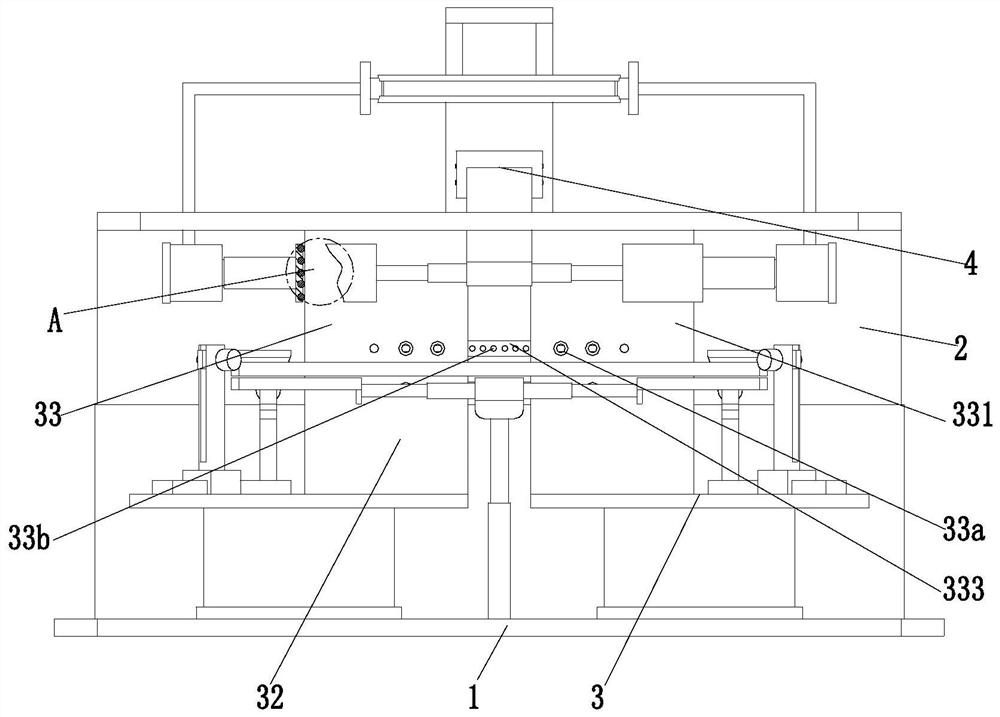

[0039] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

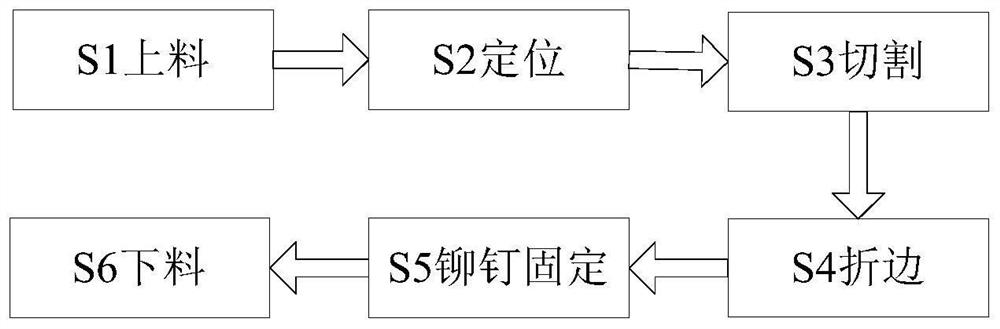

[0040] like Figures 1 to 7 As shown, a forming process for making aluminum products from an aluminum plate uses an automatic forming equipment, which includes a bottom plate 1, a mounting frame 2, a positioning cutting mechanism 3 and an edge folding mechanism 4, and adopts the above-mentioned automatic forming equipment The specific method of processing the aluminum shell is as follows:

[0041]S1. Loading: the staff places the aluminum plate to be processed on the positioning and cutting mechanism 3;

[0042] S2. Positioning: the aluminum plate is fixed by the positioning and cutting mechanism 3 to prevent the aluminum plate from sliding during subsequent processing;

[0043] S3. Cutting: Cut out the dividing grooves at the four top corners of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com