Cleaning device for sheet metal part production

A cleaning device and a technology for sheet metal parts, applied in the field of sheet metal processing, can solve problems such as the classification and collection of waste that cannot be cleaned, and achieve the effects of increasing the sandblasting reuse rate, improving the cleaning process, and improving the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

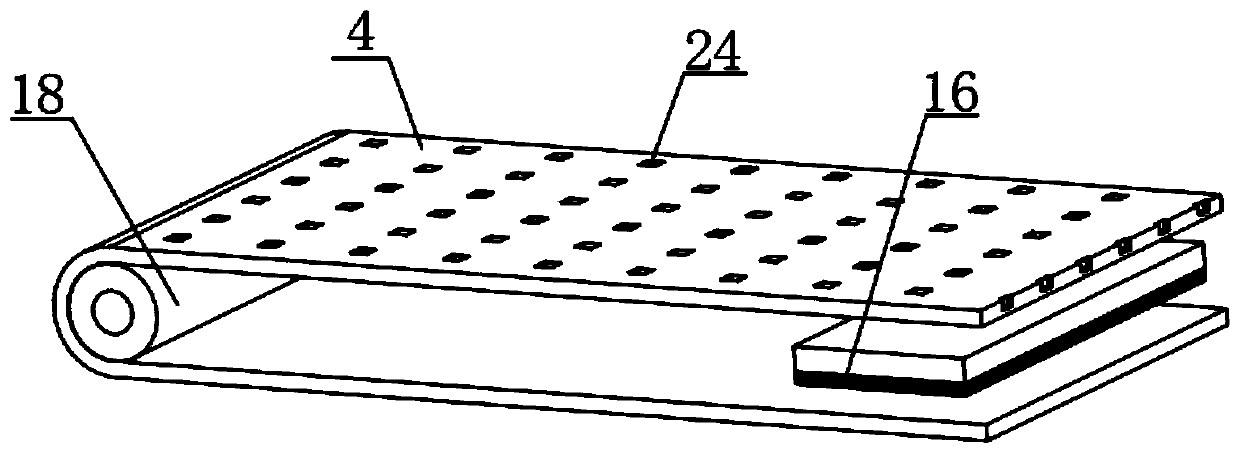

[0030] A cleaning device for sheet metal production, such as Figure 1-2 Shown, comprise main chassis 17,, the slide rail 10 that horizontal setting is connected with by bolt in the middle of the top inner wall of main chassis 17, the bottom inner wall of sliding track 10 is slidably connected with the suspension bar 11 that vertical setting is arranged, the both sides of main chassis 17 Both sides inner wall bottoms are all connected with the fixed base plate 23 that horizontally arranges by bolt, the top inner wall of fixed base plate 23 and the top of main frame 17 are sleeved with vertically arranged rotating central axis 7, and the circumference outer wall of rotating central axis 7 is covered. Connect with the cleaning brush 15 that is vertically arranged, the inner wall on both sides of the main frame 17 is connected with the sandblasting pipe 6 that is horizontally arranged by bolts, and the bottom between the two ends inner walls of the main frame 17 is sleeved with tw...

Embodiment 2

[0034] A cleaning device for sheet metal production, such as Figure 1-5Shown, one side inner wall top of main frame 17 is connected with the dust removal cabinet 25 that vertically arranges by bolt, and the top of dust removal cabinet 25 is equipped with the air intake grille 27 that horizontally arranges, between the top and the bottom of air intake grille 27 A vertically arranged air inlet 28 is installed between them, and the top entrance of the air inlet 28 is narrow, and one side of the dust removal cabinet 25 is provided with a first hole, and the first hole is sleeved with a fan barrel 26, and the fan barrel 26 A fan is socketed on the inner wall of the circumference, and the fan cylinder 26 is socketed on one side of the main chassis 17 .

[0035] In this embodiment, when in use, a vertical dust removal cabinet 25 is installed on the side inner wall of the main chassis 17, the dust removal cabinet 25 can absorb debris and dust generated by cleaning, and the top of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com