Gluing device for continuous glue feeding of PCB

A technology of PCB board and gluing device, which is applied to devices and coatings that apply liquid to the surface, can solve problems such as interruption of gluing work and inability to operate continuously, and achieve the effect of stable gluing and quality assurance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

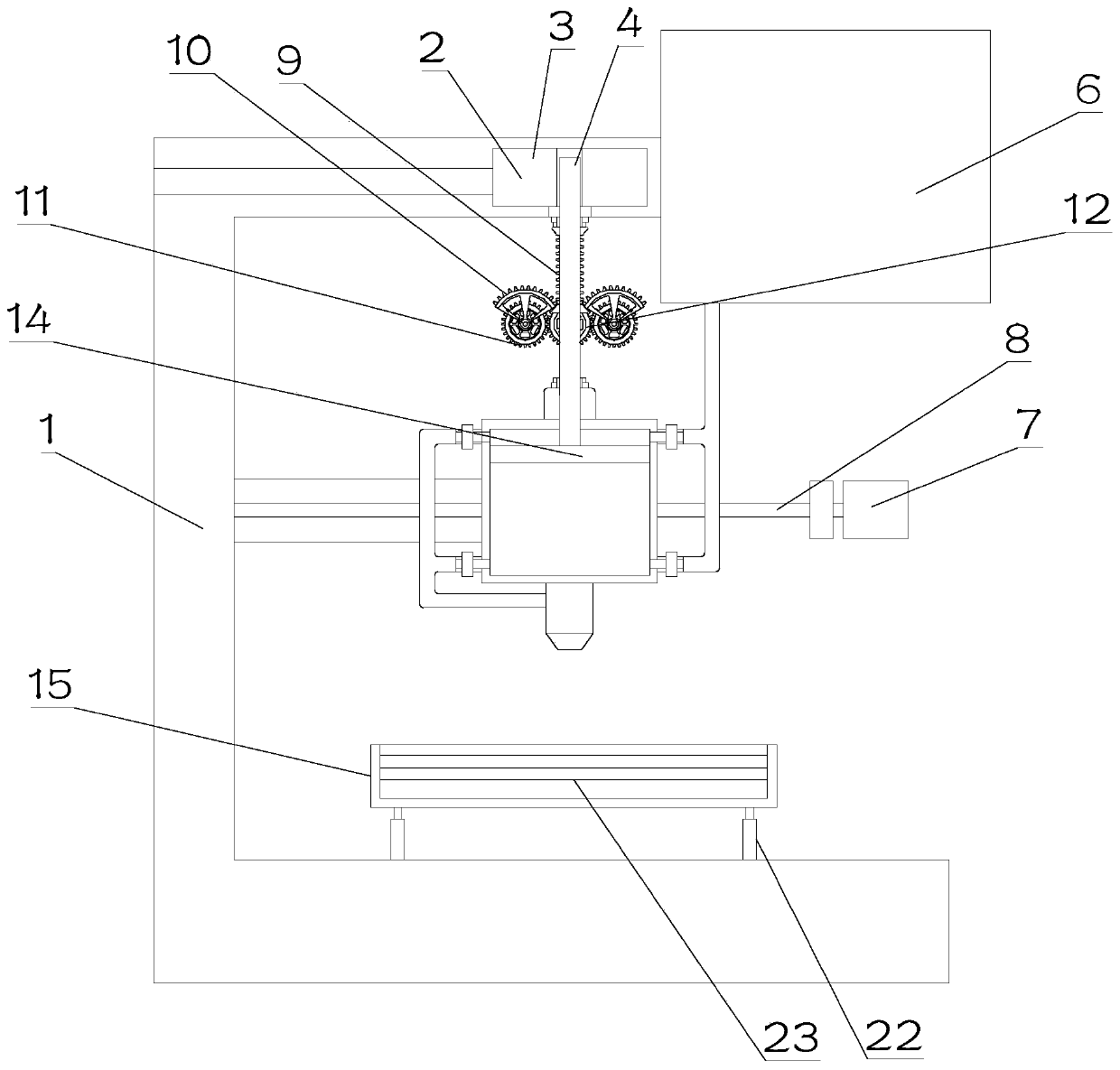

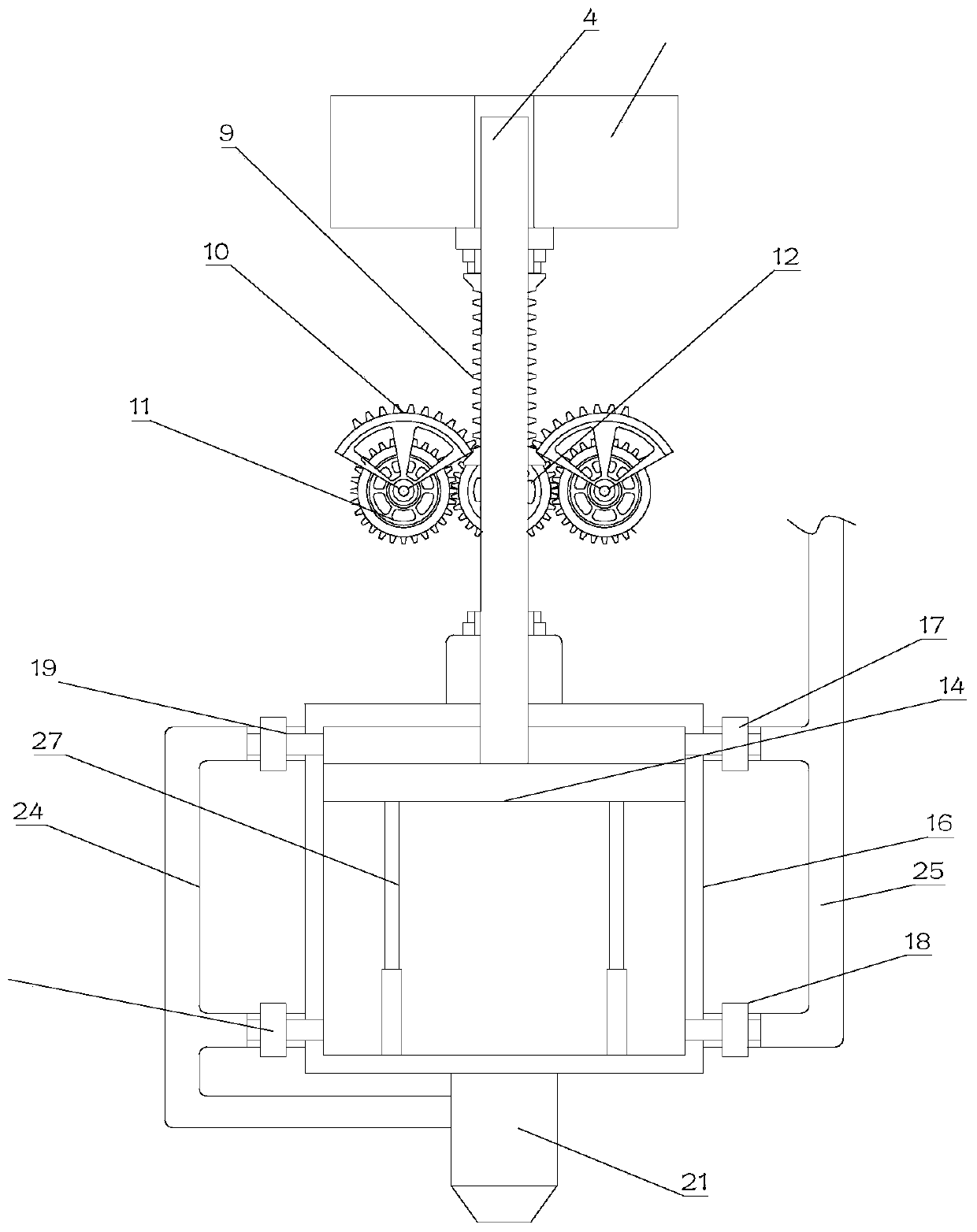

[0023] see Figure 1~3 , in Embodiment 1 of the present invention, a gluing device for continuous gluing for PCB boards, comprising a main body frame 1, a gluing mechanism 2 is arranged on the main frame 1, and a bearing is arranged below the gluing mechanism 2 Seat 15, the bottom of the bearing seat 15 is installed on the lifting cylinder 22, the lifting cylinder 22 is fixedly installed on the main frame 1, and the lifting cylinder 22 is set to adjust the height of the PCB board on the bearing seat 15, so that it can be glued The bottom of the mechanism 2 is close to the glue outlet 21, which is convenient for glue application; the glue outlet mechanism 2 includes a glue box 16 and a support block 3 slidably arranged on the main frame 1, and the glue box 16 and the support block 3 are fixedly connected , the inside of the plastic box 16 is provided with a piston 14 that slides up and down. The upper part of the piston 14 is provided with a C check valve 19 and an A check valv...

Embodiment 2

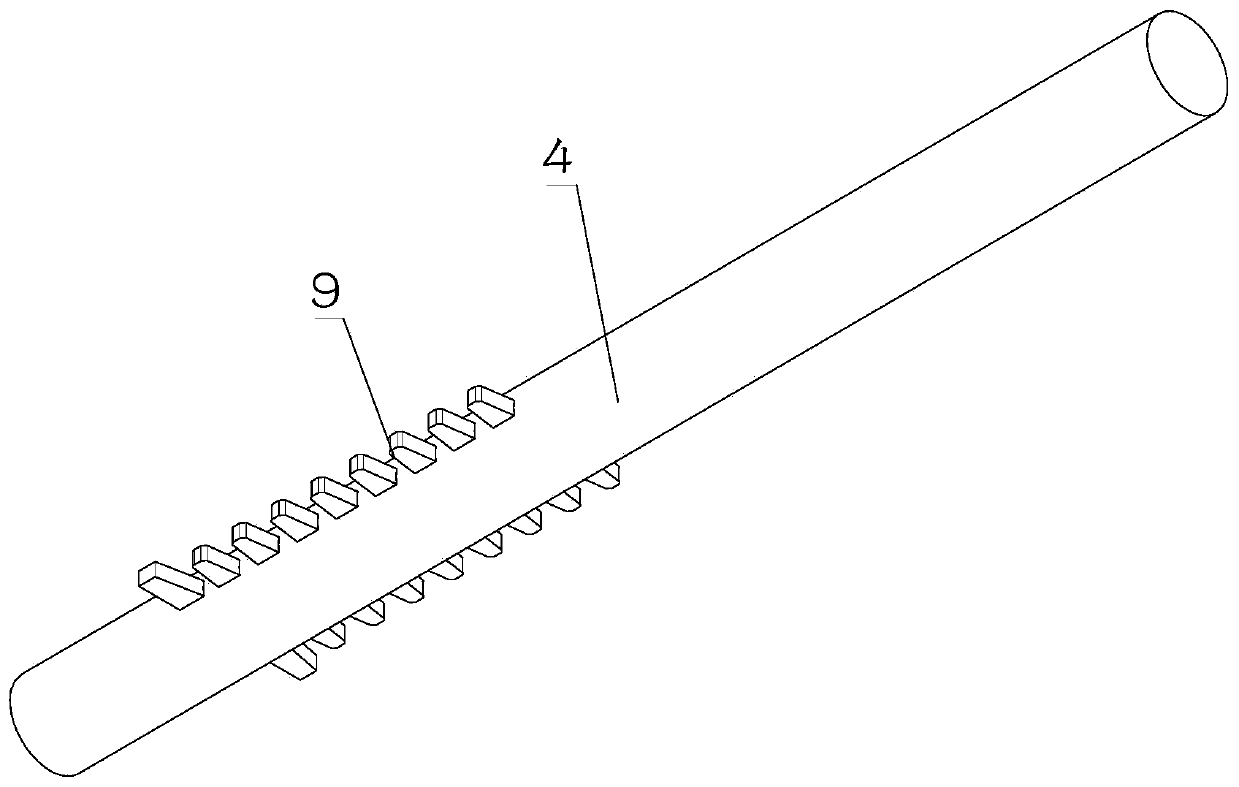

[0026] see Figure 1~3 The main difference between this embodiment 2 and embodiment 1 is that the reciprocating assembly includes a moving rod 4, the lower end of the moving rod 4 is fixedly mounted on the piston 14, and the upper end of the moving rod 4 is set in the through hole on the support block 3 Among them, the two sides of the moving rod 4 are respectively provided with racks 9, the racks 9 on both sides are respectively meshed with the incomplete gears 10 on both sides intermittently, and the incomplete gears 10 on both sides are coaxial with the driven gear 11 Set, the driven gear 11 on both sides meshes with the driving gear 12 respectively, the driving gear 12 provides power for the rotation of the driven gear 11, the driving gear 12 is installed on the output end of the B motor, and the B motor is fixedly installed on On the rubber box 16; the B motor drives the driving gear 12 to rotate, the driving gear 12 drives the driven gear 11 on both sides to rotate, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com