Trimming mechanism for hedge trimmer and hedge trimmer

A hedge trimmer and hedge technology, applied in the field of greening equipment, can solve the problems of low pruning efficiency, energy waste, difficult pruning, etc., and achieve the effect of expanding the adjustable range and orientation of pruning, improving flexibility, and easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

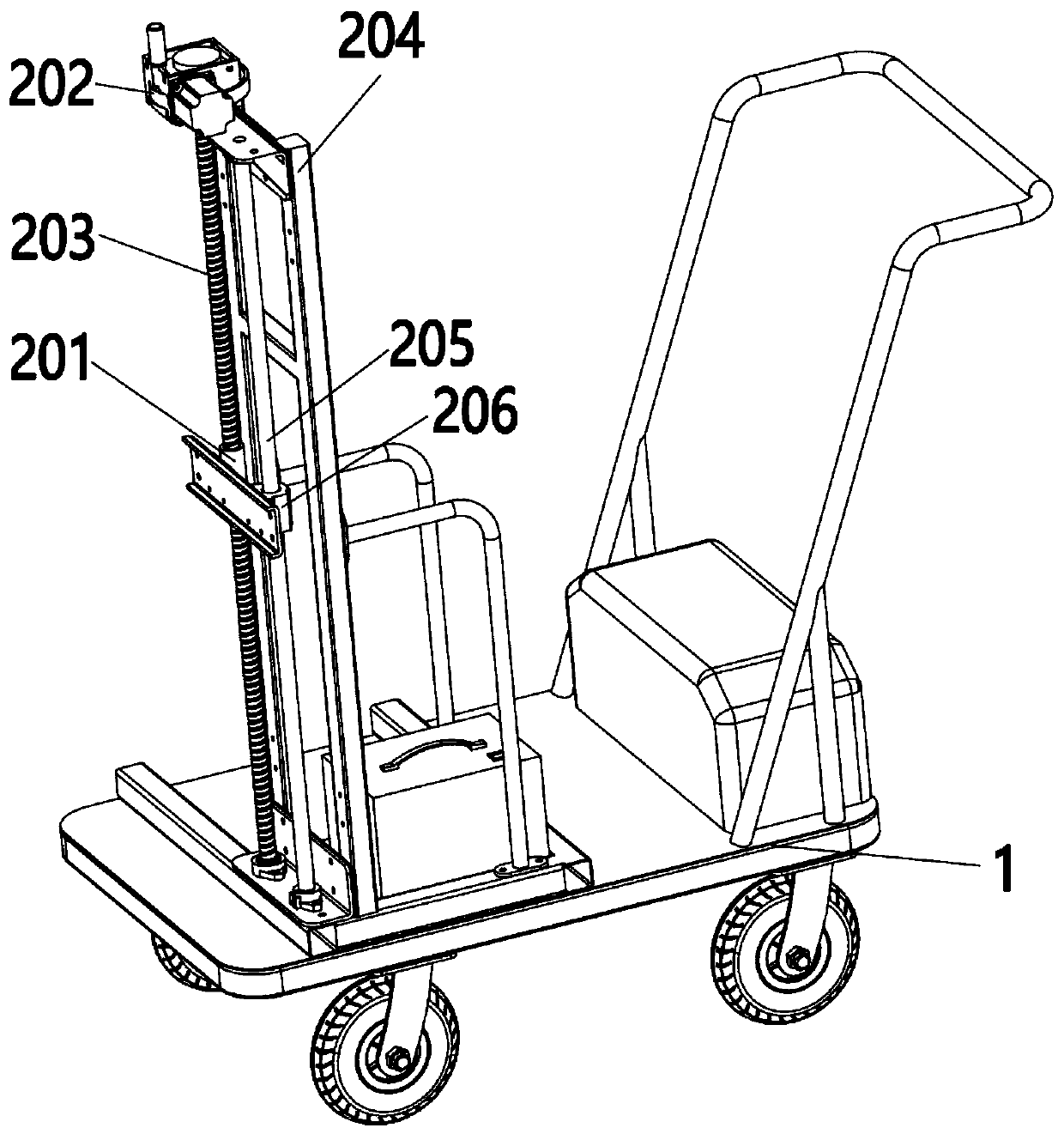

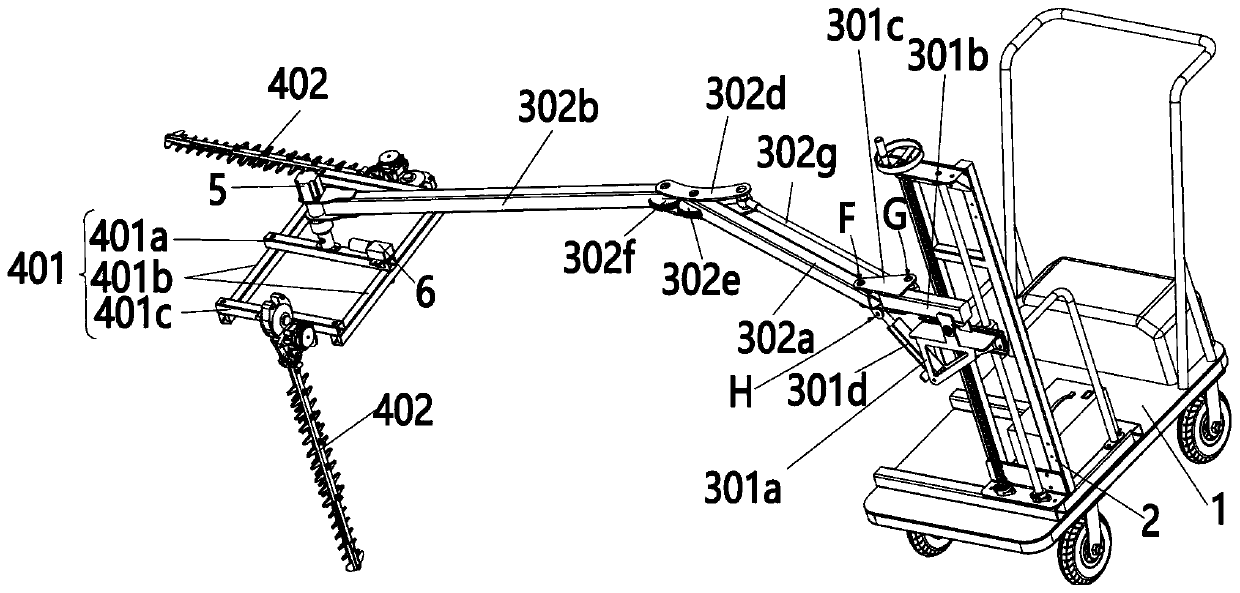

[0034] Such as Figure 1 to Figure 6 As shown, the trimming mechanism 4 includes a movable connection frame 401 and a hedge shear 402 arranged on the movable connection frame 401. The movable connection frame 401 includes a fixed pipe 401a connected to the trimmer firmware, and the end of the fixed pipe 401a is provided with a drive pipe. 401b, the hedge shears 402 are pivotally connected to the end of the drive tube 401b, the connection between the fixed tube 401a and the clipper firmware is provided with a first drive transmission assembly 5 that drives the fixed tube 401a to rotate, and the connection between the fixed tube 401a and the drive tube 401b is provided There is a second drive transmission assembly 6 that drives the drive tube 401b to rotate.

[0035]The drive tube 401b and the fixed tube 401a adopt the above-mentioned connection method. Due to the self-locking performance of the second drive transmission assembly 6, when the second drive transmission assembly 6 ...

Embodiment 2

[0051] The difference between this embodiment and Embodiment 1 is that, in order to further improve the stability of the hedge shears 402 in the pruning process, two drive pipes 602 are provided, including the active drive shaft 401ba connected to the second drive transmission assembly 6 and the active drive shaft 401ba in the active drive Driven by the shaft 401ba, the driven drive pipe 401bb rotates. A transmission connecting pipe 401c is provided between the active driving shaft 401ba and the driven driving pipe 401bb. The hedge shears 402 are pivotally connected to the connecting pipe 401c. Specifically, the end of the fixed pipe 401a The connecting pipe 401c includes a left connecting pipe 401c and a right connecting pipe 401c symmetrically arranged on both sides of the fixed pipe 401a, and the left connecting pipe 401c and the right connecting pipe 401c are pivotally connected with hedge shears 402, The symmetrical setting enables two hedge shears 402 to work at the same ...

Embodiment 3

[0055] A hedge trimmer, comprising a connecting piece on which the trimming mechanism described in Embodiment 1 or Embodiment 2 is arranged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com