Zintl-phase thermoelectric material with hexagonal ZrBeSi structure and preparation method of Zintl-phase thermoelectric material

A technology of phase thermoelectric and thermoelectric devices, applied in the field of Zintl phase thermoelectric materials with hexagonal ZrBeSi structure and its preparation, can solve the problems of high price and low reserves, and achieve high thermoelectric merit value and rich system effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

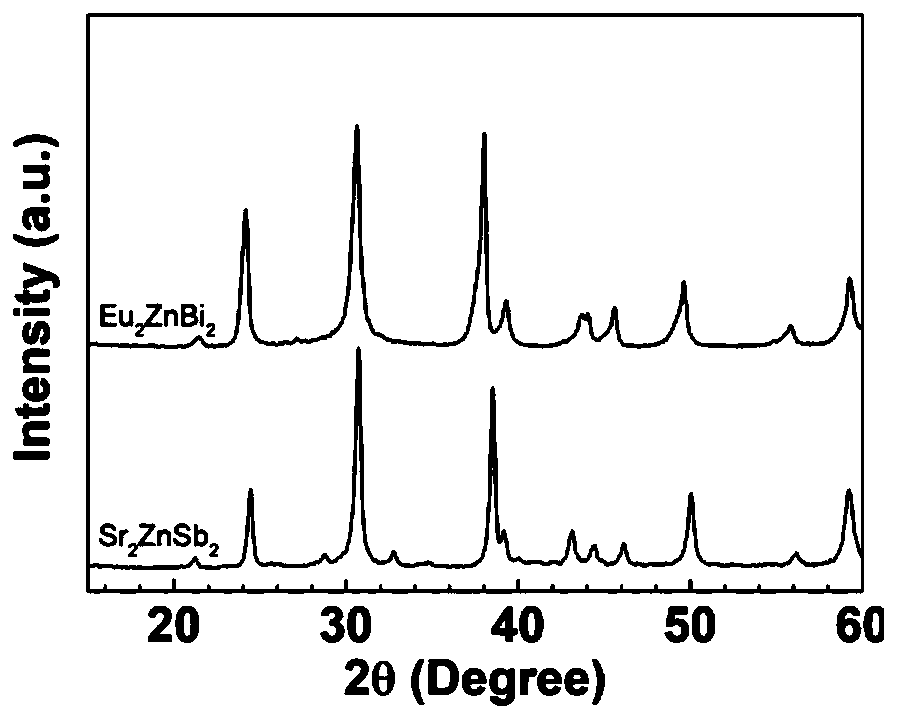

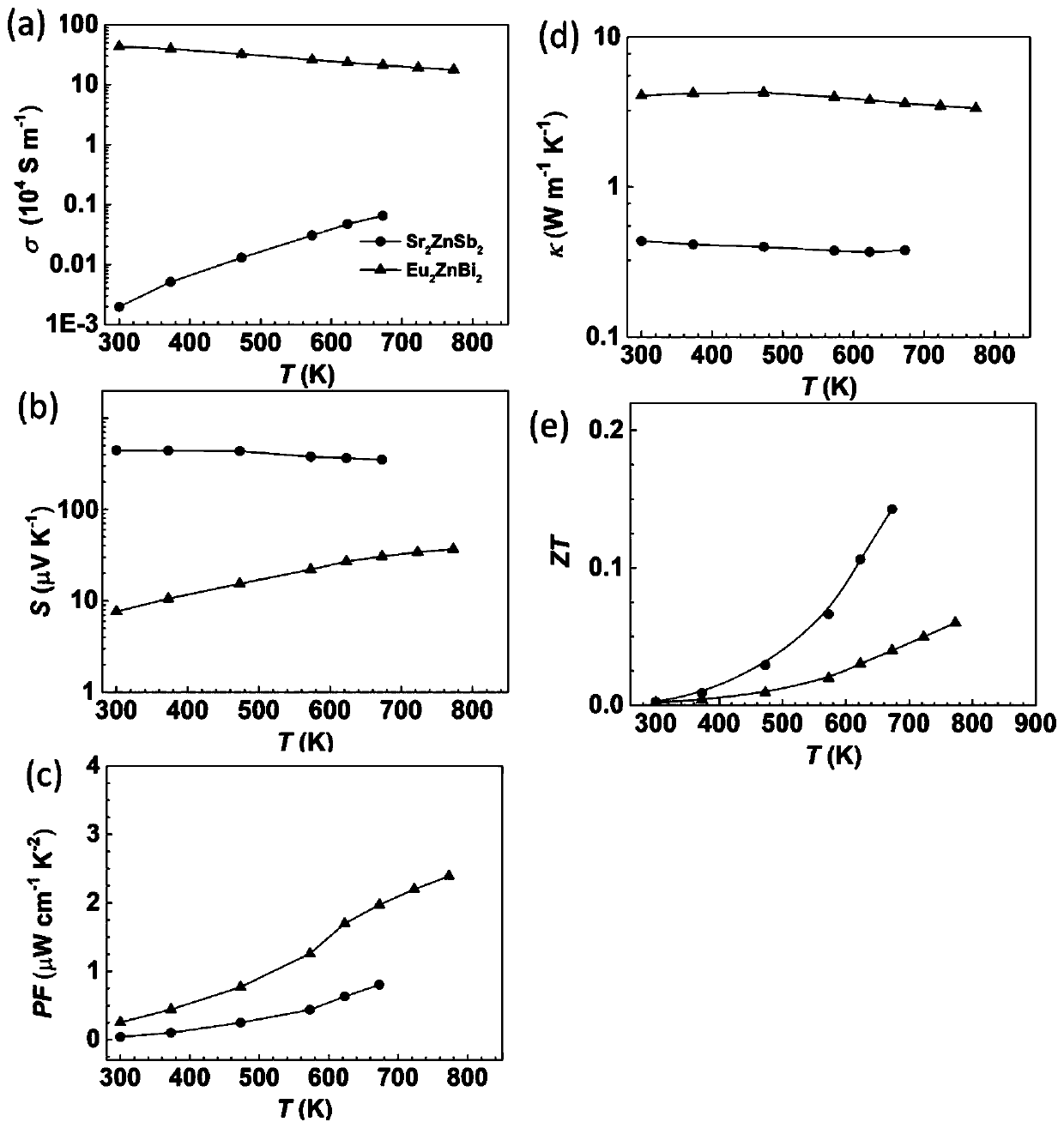

[0041] In this example, the above preparation method was used to obtain Eu 2 ZnB 2 、Sr 2 ZnSb 2 sample, and for Eu 2 ZnB 2 、Sr 2 ZnSb 2 The samples were characterized by XRD, such as figure 1 It can be seen that single-phase Eu 2 ZnB 2 and Sr 2 ZnSb 2 material, and such a 2 BC 2 Type materials have certain thermoelectric properties.

Embodiment 2

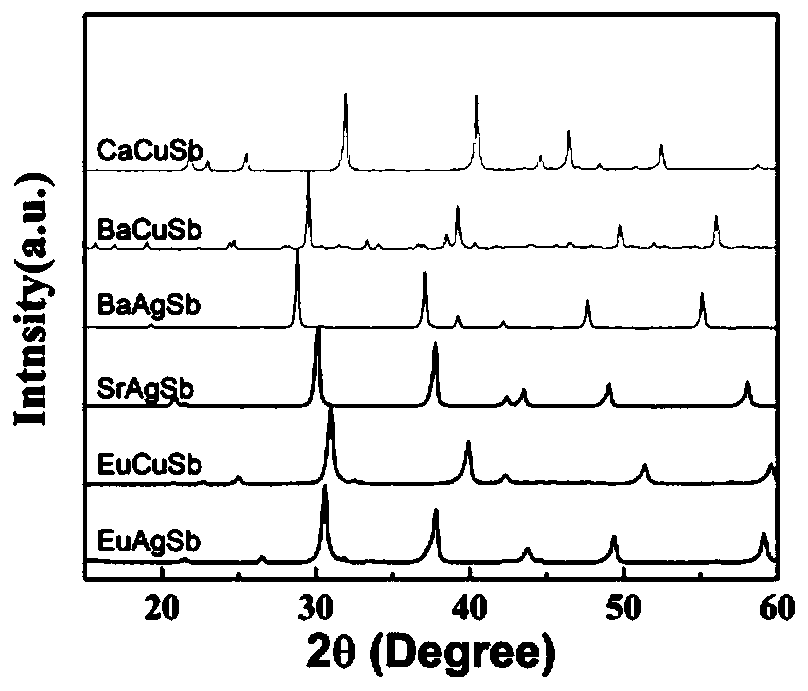

[0043] In this example, EuAgSb, EuCuSb, SrAgSb, BaAgSb, BaCuSb, and CaCuSb samples were respectively obtained by using the above-mentioned preparation method, and XRD and thermoelectric performance tests were carried out on the above-mentioned samples, and the results are as follows image 3 and Figure 4 shown. The results show that the material that can be prepared by this method is a single phase, and the material with the chemical formula DEF has certain thermoelectric properties.

Embodiment 3

[0045] The present embodiment adopts the above-mentioned preparation method to obtain Eu 2 Zn 1-0.5x Ag x Sb 2 sample, and the thermoelectric properties of the sample were tested, the results are as follows Figure 5 shown. The results show that micro-doping does not change the crystal symmetry of the material and can improve the thermoelectric properties of the material.

[0046] In addition, the Eu of the above-mentioned embodiment 2 ZnB 2 、Sr 2 ZnSb 2 , EuAgSb, EuCuSb, SrAgSb, BaAgSb, BaCuSb, CaCuSb, Eu 2 ZnSb 2 Compared with the prior art thermoelectric material SrZn 2 Sb 2 、BaZn 2 Sb 2 、EuZn 2 Sb 2 、EuCd 2 Sb 2 , CaAgSb were compared, the results are shown in Table 2. It can be seen from the comparison of the results in Table 2 that the crystal space group of the Zintl phase thermoelectric material with the ZrBeSi structure of the present embodiment is P6 3 / mmc, with prior art SrZn 2 Sb 2 、BaZn 2 Sb 2 、EuZn 2 Sb 2 、EuCd 2 Sb 2 Although CaAgSb a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com