Railway wagon floor damage fault image identification method

A technology for image recognition and railway wagons, which is applied in image enhancement, image analysis, image data processing, etc. It can solve the problems of low detection rate, fatigue and omission of vehicle inspectors, and achieve easy training, improved recognition recall rate, The effect of improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

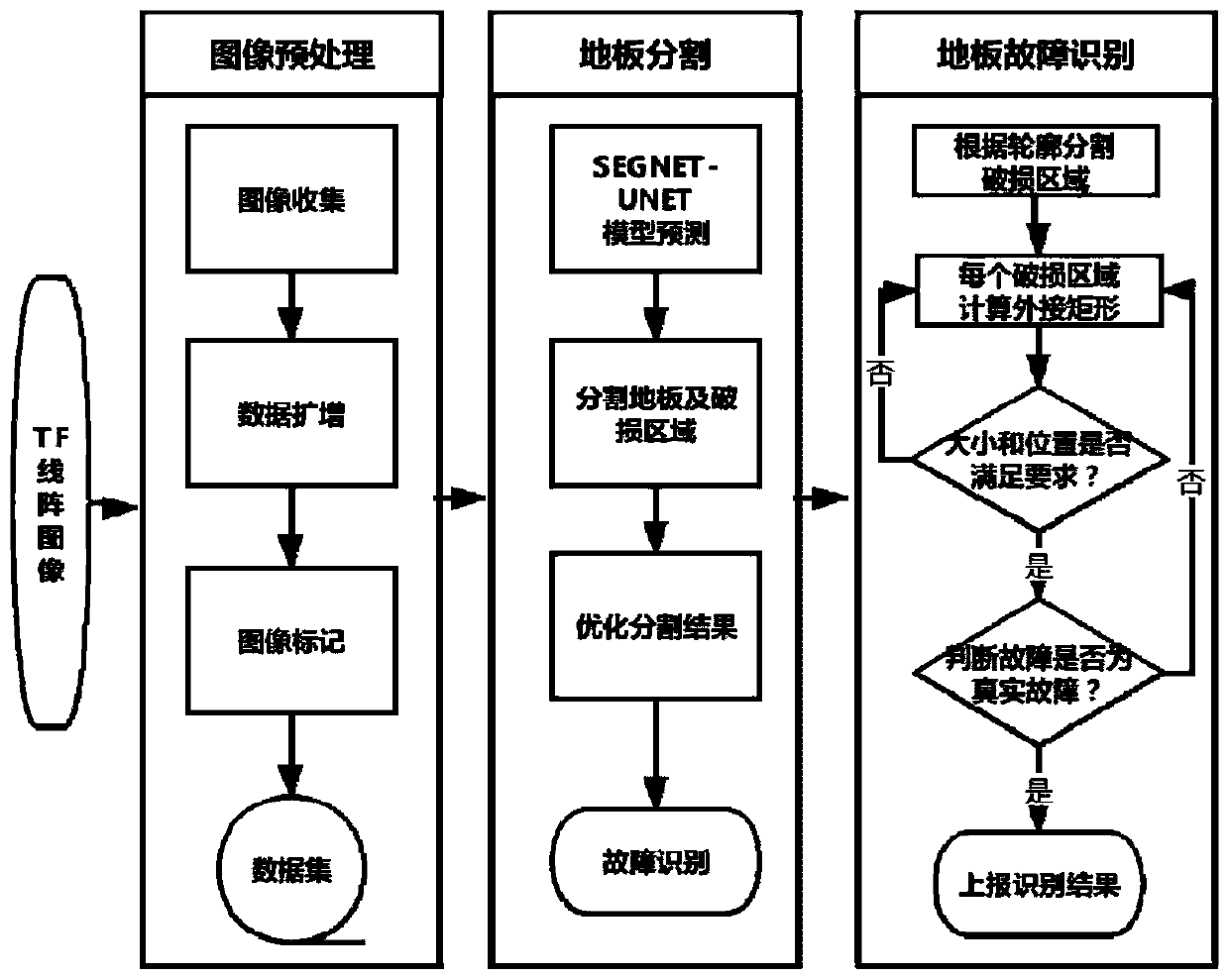

[0040] Specific Embodiment 1: This embodiment will be described in detail with reference to the figure. A method for image recognition of damaged fault images on the floor of railway wagons described in this embodiment includes the following steps:

[0041] Step 1: Obtain high-definition line scan images of passing trucks;

[0042] Step 2: Cut out the area of the part to be recognized from the image according to prior knowledge, and establish a sample data set;

[0043] Step 3: Perform data amplification on the sample data set;

[0044] Step 4: Mark the images in the dataset;

[0045] Step 5: Generate a data set from the original image and labeled data, and train the model;

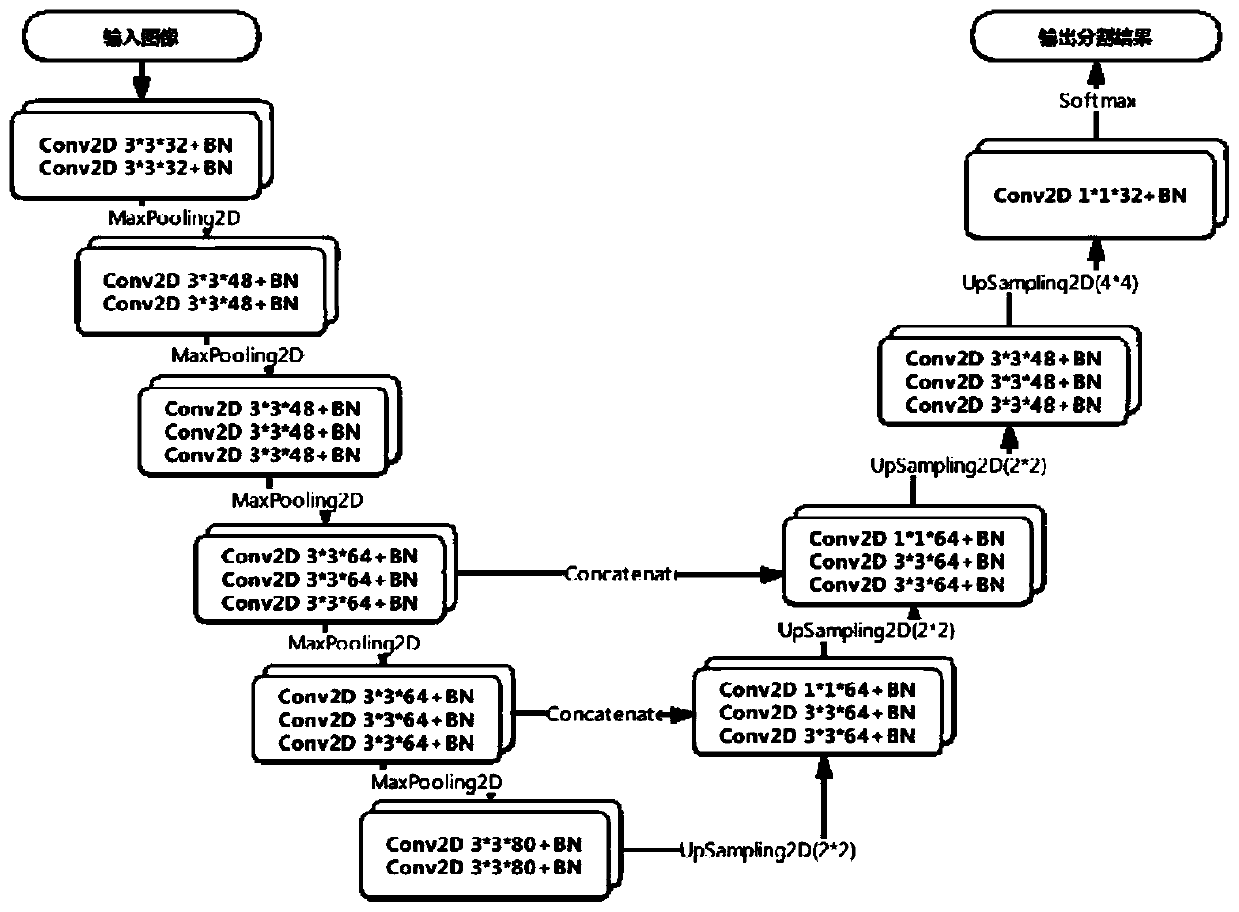

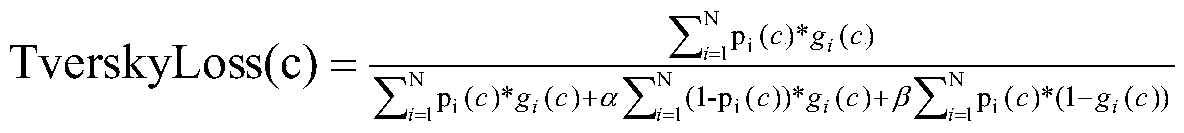

[0046] Step 6: Use the SEGNET-UNET network to segment the image, and mark each segmented part;

[0047] Step 7: For the floor segmentation result, divide the image into multiple fault areas according to the contour information. For each fault area, judge whether there is a floor damage fault accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com