Calculation method for predicting influence of swirl distortion intake air on performance of aero-engine

A technology of aero-engine and swirl distortion, applied in the direction of calculation, computer-aided design, design optimization/simulation, etc., to achieve the effect of accurate calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further explained below in conjunction with the accompanying drawings.

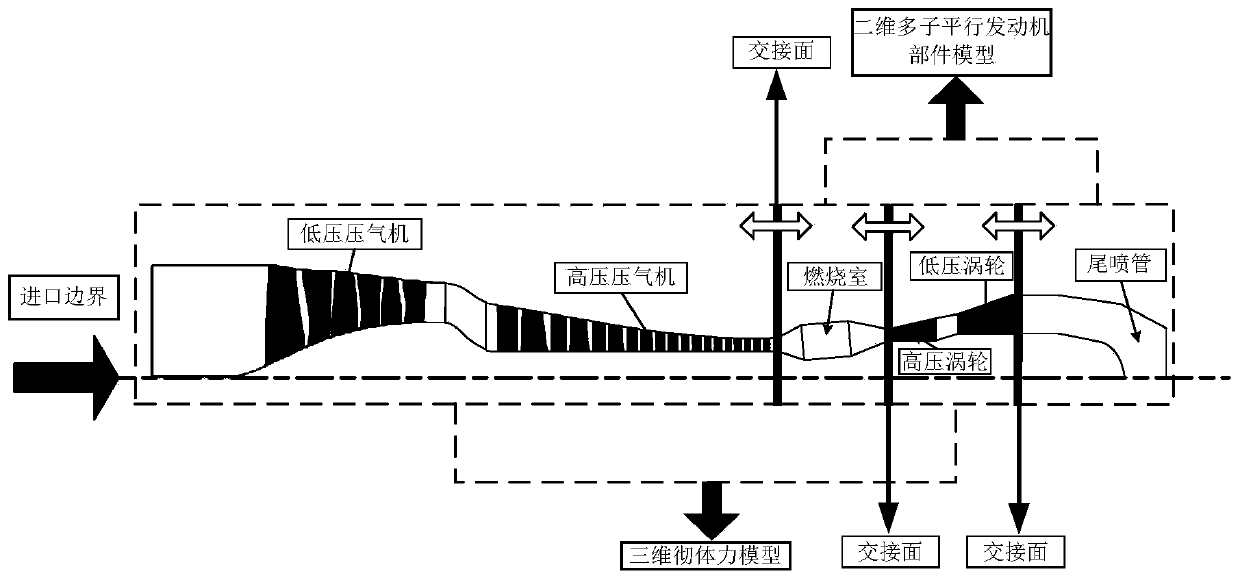

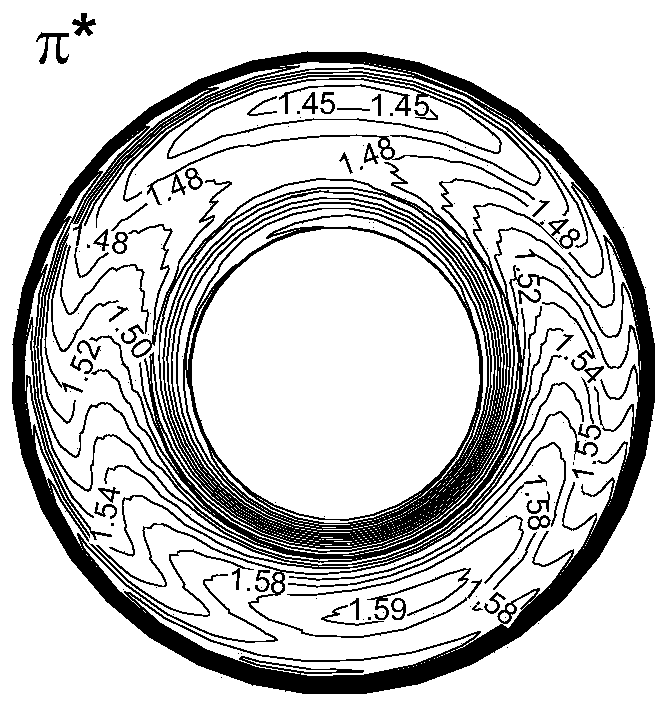

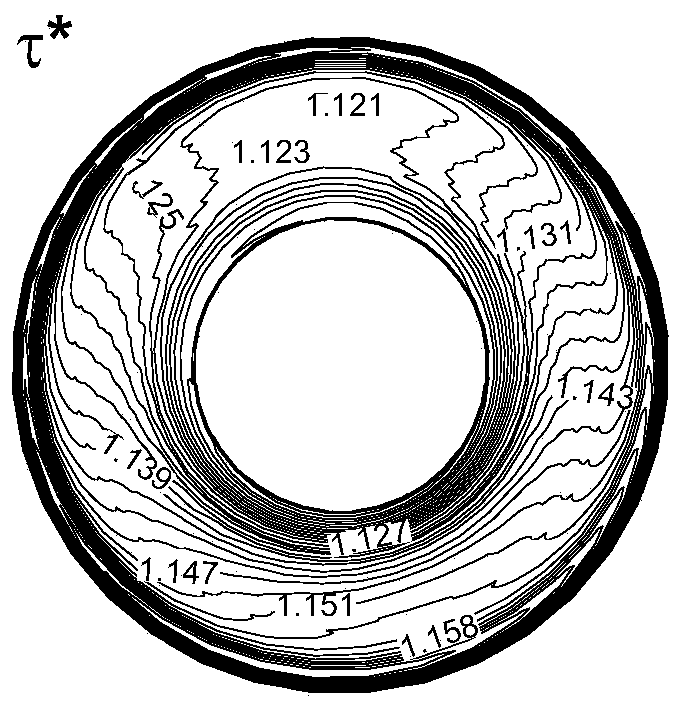

[0035] Firstly, a three-dimensional physical force model is used to describe the turbomechanical components of the engine, including multi-stage compressors and multi-stage turbines. Then a two-dimensional multi-subparallel engine component model is used to describe the combustion chamber and exhaust pipe. Then, a numerical transfer interface is set between the 3D body force model and the 2D multi-subparallel engine model to realize the conversion between 3D and 2D calculations. At the same time, the rotor dynamics equation and the engine control law are supplemented to realize the work balance calculation between the turbine and the compressor, and determine the engine speed in real time. Finally, by applying large-scale swirl distortion to the inlet boundary of the compressor, the influence of swirl distortion on the overall performance of the aero-engine and the ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com