Real-time data feedback artificial intelligence control system and control method thereof

A technology of artificial intelligence and control system, applied in the direction of program control, separation method, electrical program control, etc. Reduce wear and tear and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The preferred embodiments of the present invention will be described below with reference to the accompanying drawings. It should be understood that the preferred embodiments described herein are only used to illustrate and explain the present invention, but not to limit the present invention.

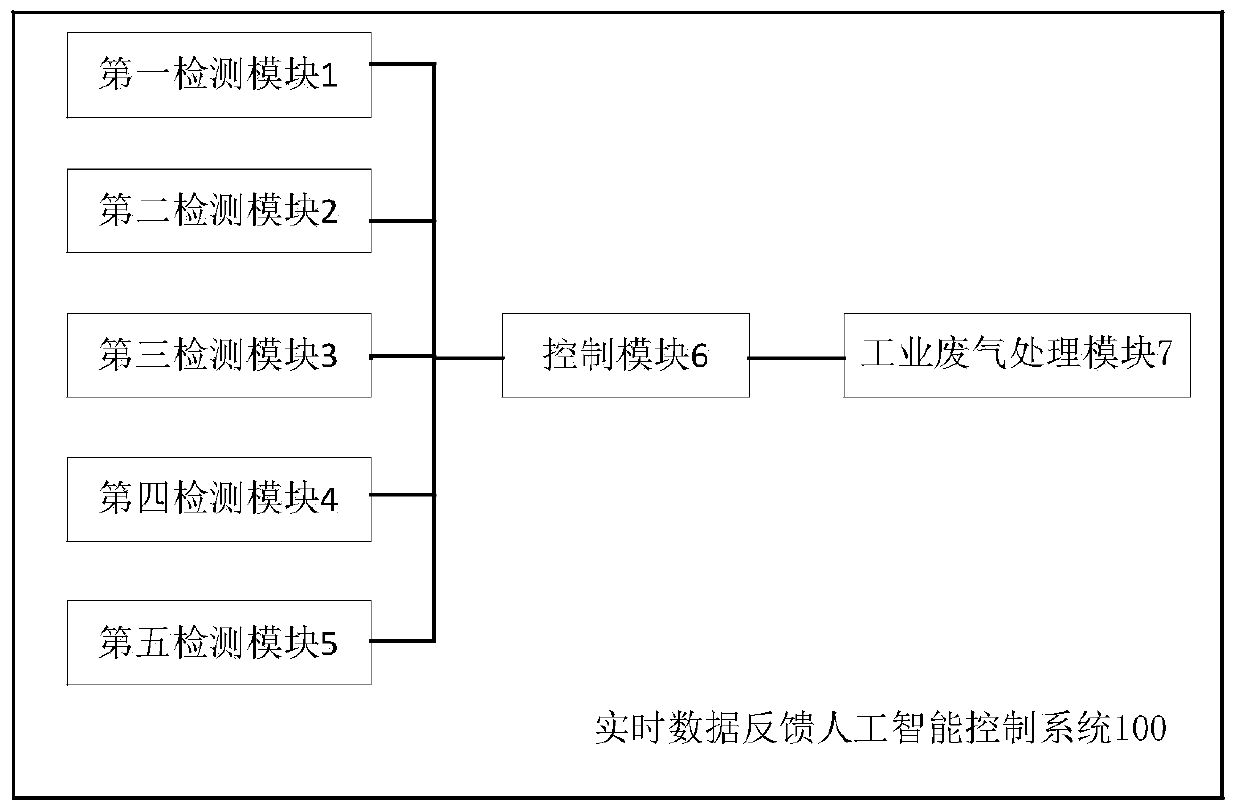

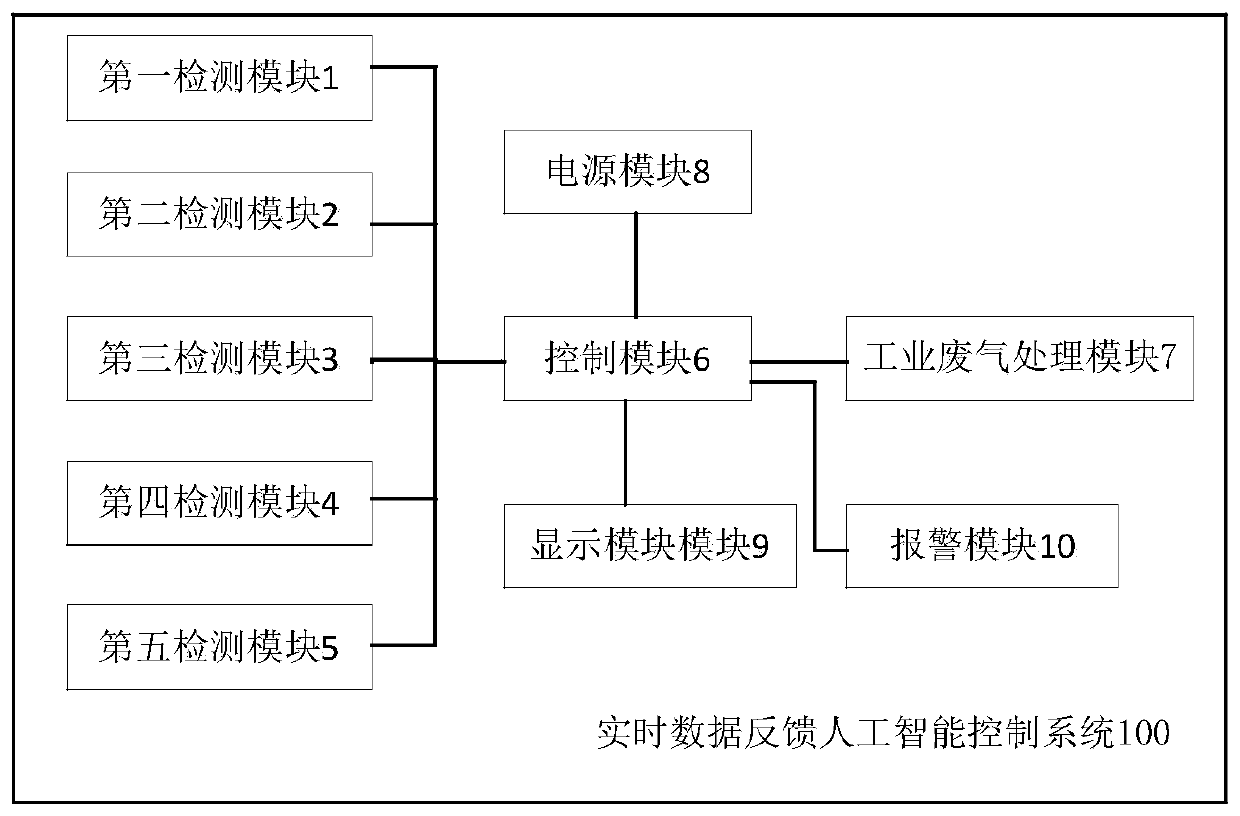

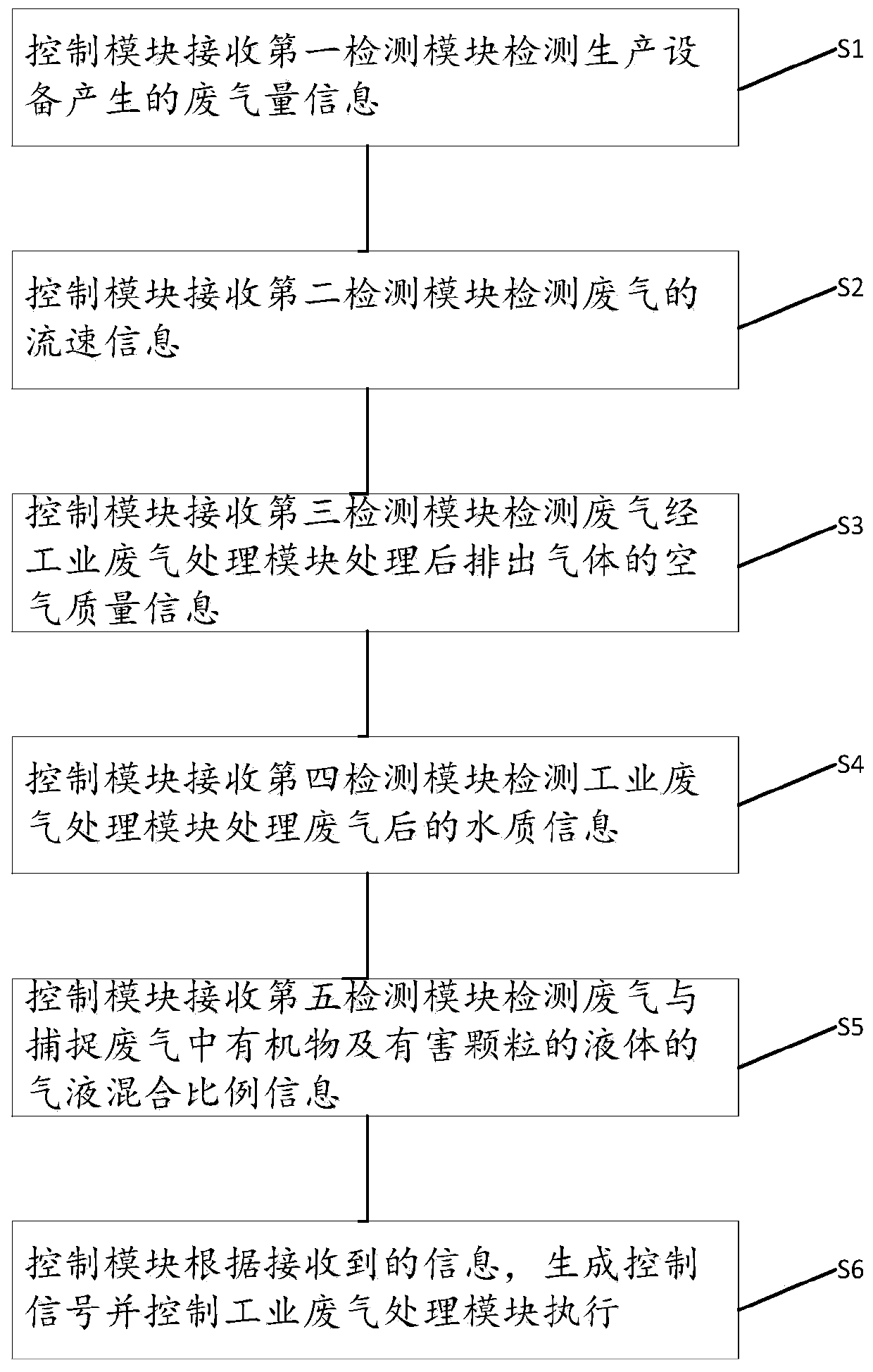

[0060] Reference below Figure 1 to Figure 3 The real-time data feedback artificial intelligence control system 100 and the control method thereof provided by the embodiments of the present invention will be described.

[0061] Before introducing the real-time data feedback artificial intelligence control system 100 and its control method provided by the present disclosure, the application scenarios involved in the various embodiments of the present disclosure are firstly introduced. In the application scenario, the industrial waste gas treatment module 7 mainly processes the industrial organic waste gas VOCs, so that the treated waste gas meets the industrial waste gas emission...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com