Printed circuit board hole copper abnormity monitoring method

A printed circuit board and abnormal monitoring technology, which is applied in the direction of electronic circuit testing, electrical connection formation of printed components, electrical measurement, etc. Unable to use and other problems, to achieve the effect of testing the ability of the electroplating line, intuitive observation, and ingenious conception

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

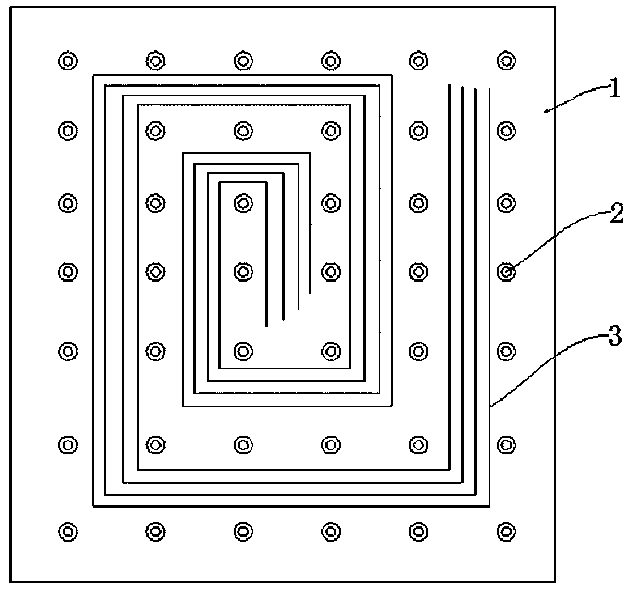

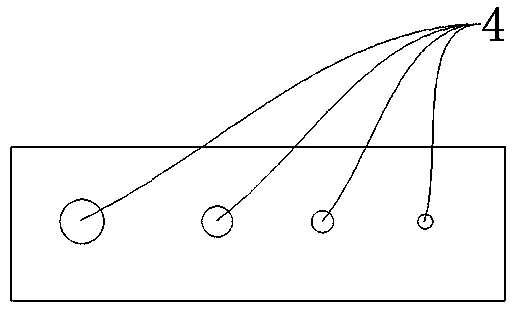

[0032] The method for monitoring the copper via hole abnormality of the printed circuit board of the present invention will be described in further detail below with reference to specific embodiments and drawings.

[0033] The present invention provides a method for monitoring copper hole abnormalities of printed circuit boards. The copper hole copper is monitored by the method for monitoring copper holes of printed circuit board. When the monitoring result shows abnormal conditions, the production can be stopped at the first time, and the cause of the defects can be checked immediately , To prevent bad circuit boards from leaving the plating process; and this monitoring method can also be used to detect blind holes, through holes 4 and the uniformity of copper plating.

[0034] Reference figure 1 with figure 2 , A non-limiting embodiment of the present invention, a method for monitoring copper anomalies in a printed circuit board hole includes the following steps:

[0035] S1: Pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com