Method for directly preparing basic cobalt carbonate by membrane electrolysis method

A technology of cobalt carbonate and membrane electrolysis, which is applied in the direction of electrolysis process, electrolysis components, cells, etc., can solve the problems of unfavorable manual operation environment, single raw material, long process, etc., and achieve the effect of cost reduction, simple operation and short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

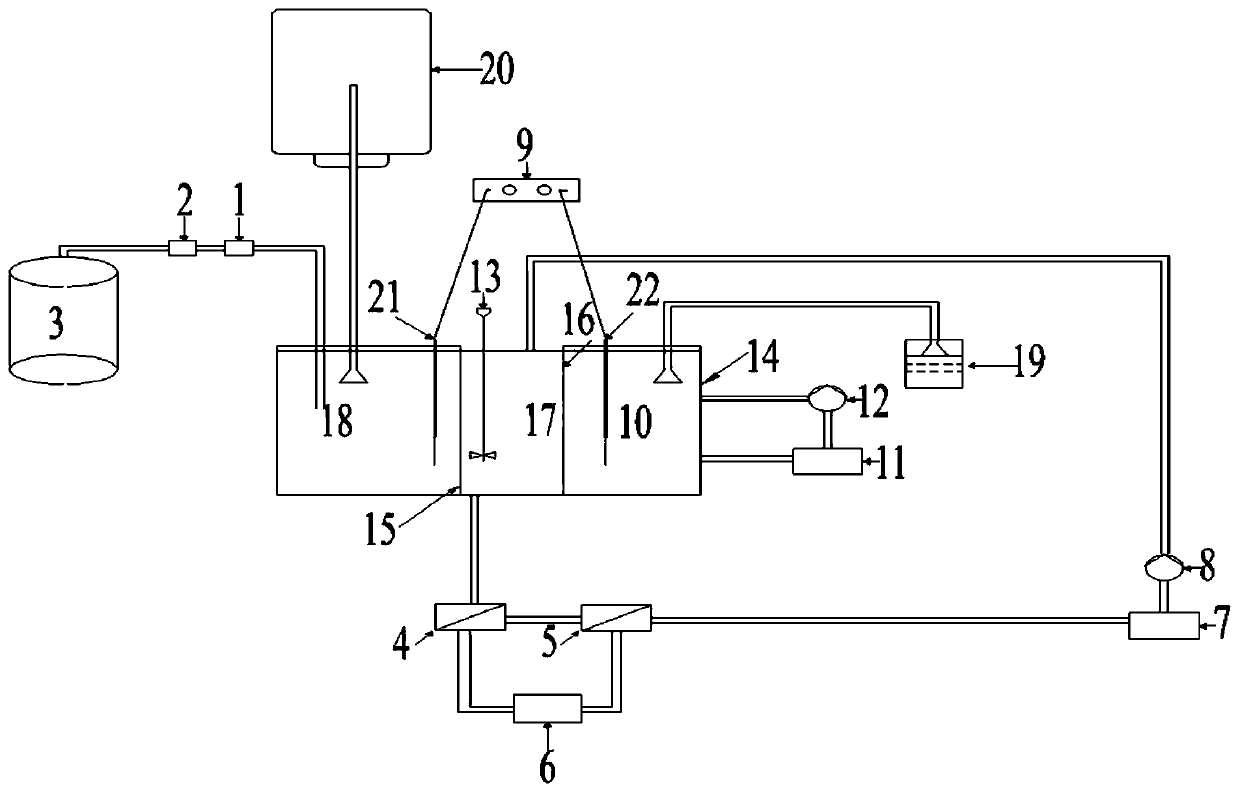

[0050] Using the electrolytic cell system, the cobalt chloride solution is placed in the anode chamber, and the electrolyte is placed in the cathode chamber and the middle chamber respectively; the anode plate in the anode chamber and the cathode plate in the cathode chamber are respectively connected to the two poles of the power supply through wires; the anode chamber and The middle chambers are separated by a cation exchange membrane, and the cathode chamber and the middle are separated by an anion exchange membrane; the middle chamber is equipped with a stirring paddle; the electrolyte is a sodium chloride solution with a concentration of 0.1mol / L; the initial concentration of the cobalt chloride solution is 0.1mol / L;

[0051] Turn on the power supply to apply direct current to the anode plate and the cathode plate, and control the current density of the anode plate to 200A / m 2 ;

[0052] Pass carbon dioxide gas into the cathode chamber, the purity of carbon dioxide gas i...

Embodiment 2

[0060] Method is with embodiment 1, and difference is:

[0061] (1) The electrolyte is a sodium chloride solution with a concentration of 0.08mol / L;

[0062] (2) the initial concentration of cobalt chloride solution is 0.3mol / L;

[0063] (3) Control the current density of the anode plate to 300A / m 2 ;

[0064] (4) Add sodium chloride to the filtrate in the second dissolving tank to make a sodium chloride solution with a concentration of 0.08 mol / L as the electrolyte and transport it to the middle chamber.

Embodiment 3

[0066] Method is with embodiment 1, and difference is:

[0067] (1) The electrolyte is a sodium chloride solution with a concentration of 0.04mol / L;

[0068] (2) the initial concentration of cobalt chloride solution is 0.5mol / L;

[0069] (3) Control the current density of the anode plate to 400A / m 2 ;

[0070] (4) Add sodium chloride to the filtrate in the second dissolving tank to make a sodium chloride solution with a concentration of 0.04 mol / L as the electrolyte and transport it to the middle chamber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com