Zero-dimensional lead-free perovskite fluorescent material as well as preparation and application thereof

A dimensional lead-free perovskite and fluorescent material technology, applied in luminescent materials, electrical components, circuits, etc., can solve the problems of inert environment, high-purity raw materials, high temperature and high pressure, etc., and achieve high fluorescence quantum yield and wide luminescence. Spectral, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

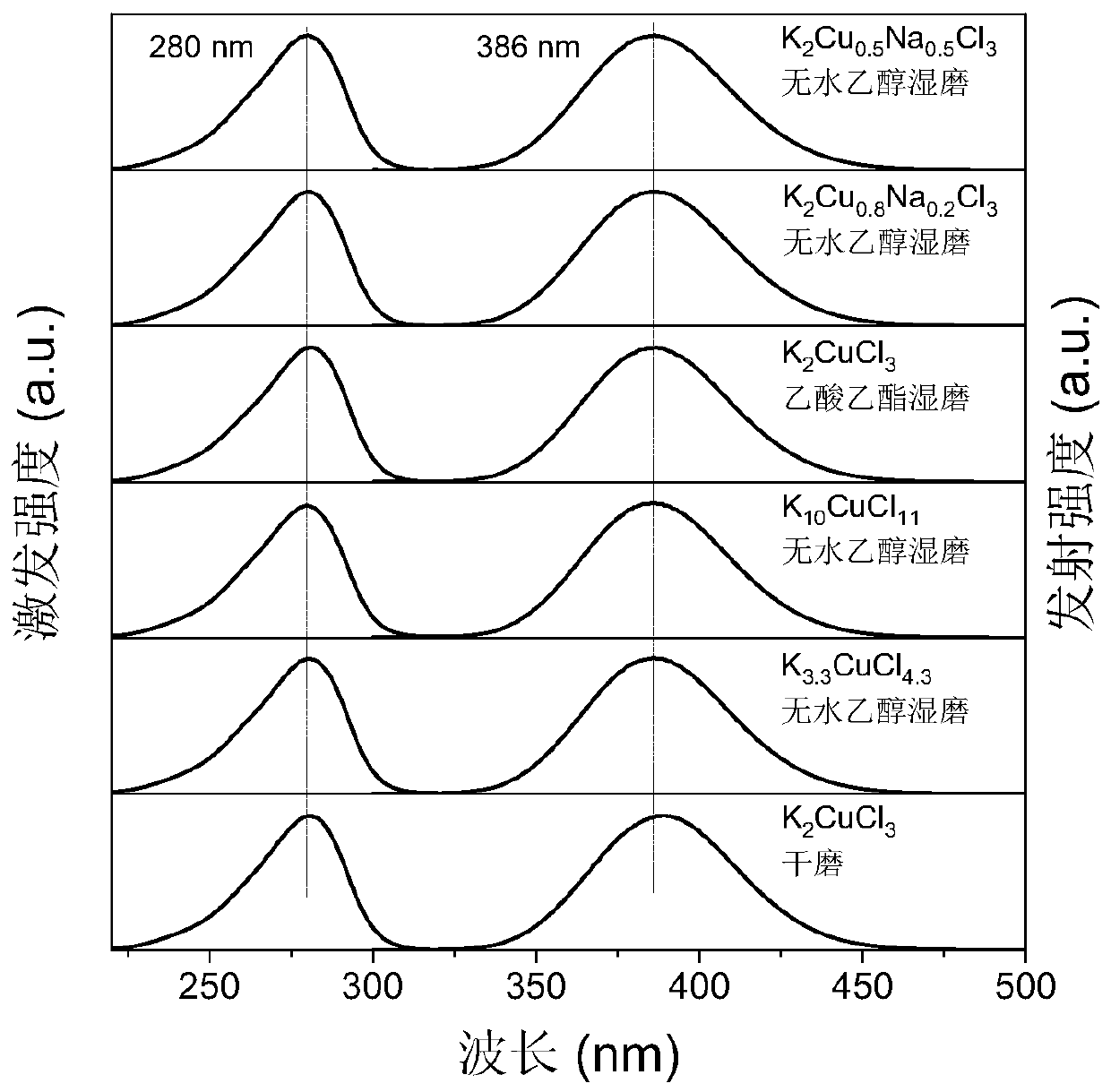

[0022] Weigh 0.2982g of KCl powder, 0.0990g of CuCl powder and 0.0584g of NaCl powder into the ball milling tank, then add 3mL of absolute ethanol and 2g of ball milling beads, set the ball milling speed to 1200r / min, and mill at room temperature for 7h, The solid-liquid separation was carried out by centrifugation, and the collected solid was dried at 80°C for 5 hours to obtain the zero-dimensional lead-free perovskite fluorescent material K 2 Cu 0.5 Na 0.5 Cl 3 , the excitation peak is 280nm, the emission peak is 386nm, and has a large Stokes shift, such as figure 2 shown.

Embodiment 2

[0024] Weigh 0.2982g of KCl powder, 0.1584g of CuCl powder and 0.0234g of NaCl powder into the ball milling tank, then add 3mL of absolute ethanol and 3g of ball milling beads, set the ball milling speed to 1500r / min, and mill at room temperature for 3h, The solid-liquid separation was carried out by centrifugation, and the collected solid was dried at 70°C for 4 hours to obtain the zero-dimensional lead-free perovskite fluorescent material K 2 Cu 0.8 Na 0.2 Cl 3 , the excitation peak is 280nm, the emission peak is 386nm, and has a large Stokes shift, such as figure 2 shown.

Embodiment 3

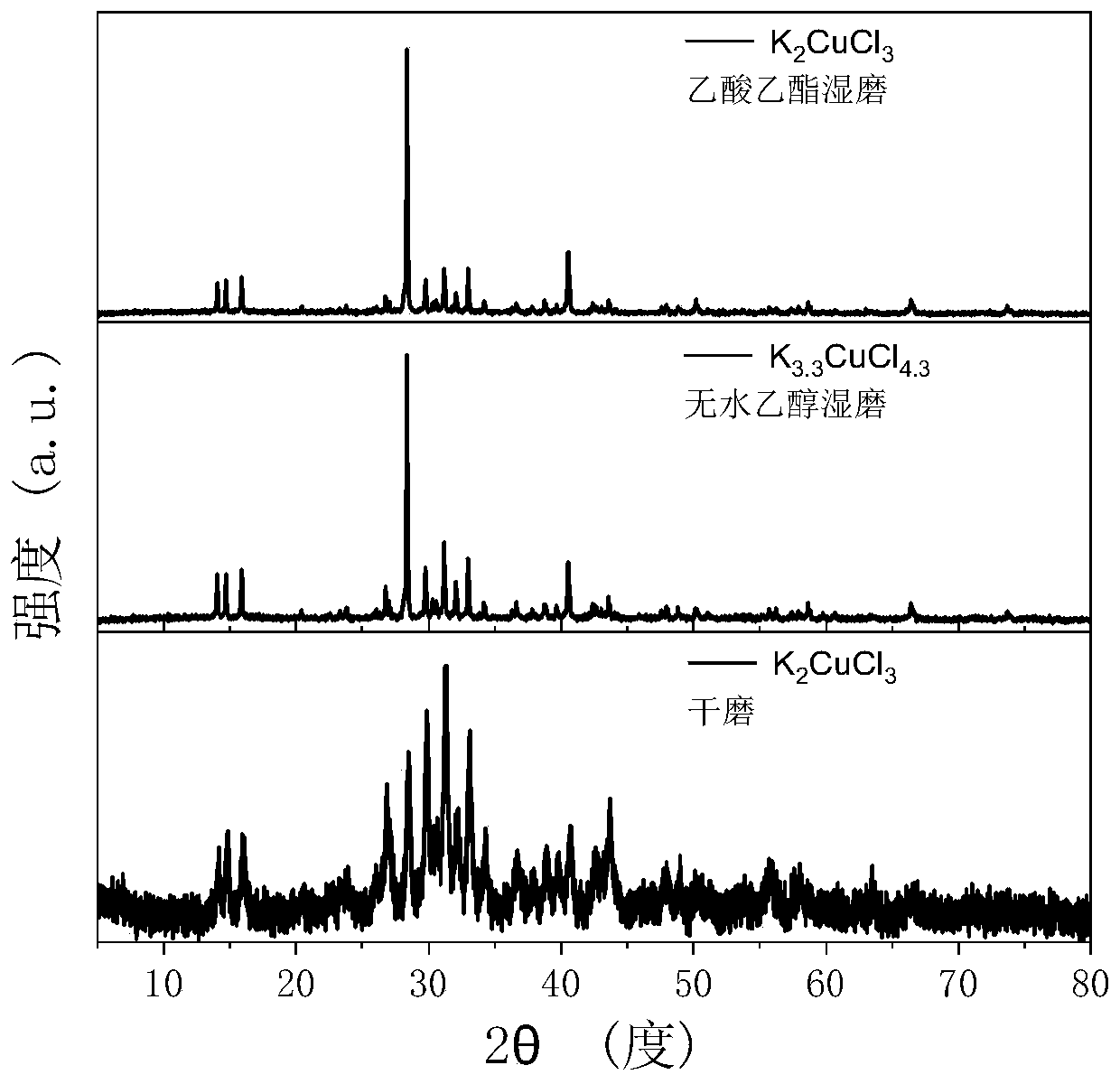

[0026]Weigh 0.2982g of KCl powder and 0.1980g of CuCl powder into the ball milling tank, then add 3mL of ethyl acetate and 4g of ball milling beads, set the ball milling speed to 1000r / min, after ball milling at room temperature for 10min, the solid-liquid Separation, and the collected solid was dried at 60°C for 3 hours to obtain the zero-dimensional lead-free perovskite fluorescent material K 2 CuCl 3 , the excitation peak is 280nm, the emission peak is 386nm, and has a large Stokes shift, such as figure 2 shown. from figure 1 It can be seen from the XRD spectrum in the figure that there is K in the solid matter after ball milling 2 CuCl 3 crystals.

PUM

| Property | Measurement | Unit |

|---|---|---|

| full width at half maximum | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com