Construction residual mud pavement brick and preparation method thereof

A pavement brick and cement technology, applied in the field of pavement bricks, can solve the problems of huge ecological environment impact, consumption of natural resources, occupation of land resources, etc., and achieve the effects of saving natural resources, improving connection strength, and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

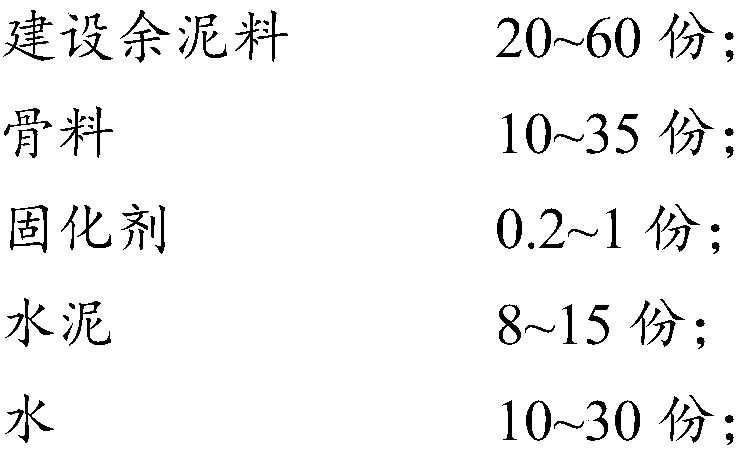

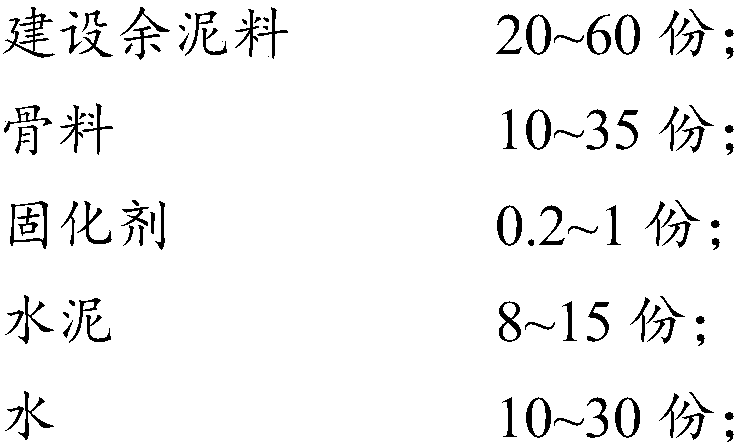

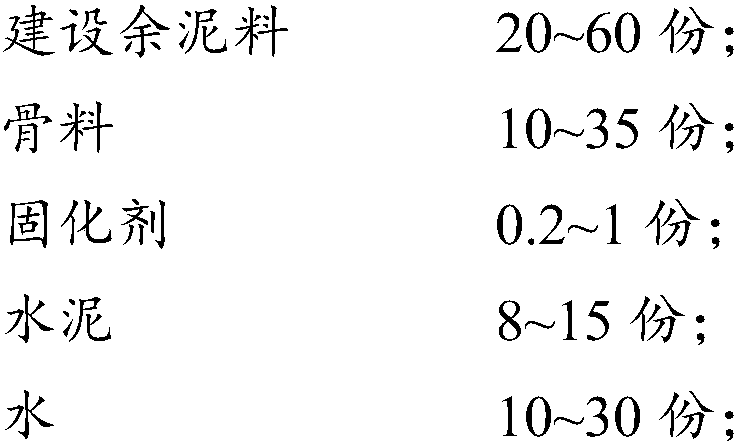

Method used

Image

Examples

Embodiment 1

[0027] Ingredients: a building mud pavement brick, the raw material ratio is as follows in parts by weight: 250kg of building mud, 125kg of aggregate, 4kg of curing agent, 50kg of cement, and 60kg of water.

[0028] The construction mud in this embodiment is a wet material or slurry obtained after simple dehydration and removal of sundries.

[0029] The aggregate in this embodiment is a fine aggregate with a particle size of 5-10 mm obtained after crushing, screening, and removing debris from construction waste.

[0030] The curing agent in this example is SIC soil curing agent dissolved in water at a ratio of 1:15 and then added.

[0031] The cement in this embodiment is Portland cement, sulphoaluminate cement, iron-aluminate cement or white cement.

[0032] The preparation method of building mud pavement brick in the present embodiment, it may further comprise the steps:

[0033] Mix and stir the construction mud, aggregate, cement, curing agent solution, and water obtaine...

Embodiment 2

[0037] Preparation of construction residue mud pavement bricks

[0038] Ingredients: a kind of construction residual mud pavement brick, according to the following raw material ratio by weight: 300 kg of construction residual mud, 150 kg of aggregate, 5 kg of curing agent, 60 kg of cement, and 75 kg of water.

[0039] The construction mud in this embodiment is a wet material or slurry obtained after simple dehydration and removal of sundries.

[0040] The aggregate in this embodiment is a fine aggregate with a particle size of 5-10 mm obtained after crushing, screening, and removing debris from construction waste.

[0041] The curing agent in this example is SIC soil curing agent dissolved in water at a ratio of 1:15 and then added.

[0042] The cement in this embodiment is Portland cement, sulphoaluminate cement, iron-aluminate cement or white cement.

[0043] The preparation method of building mud pavement brick in the present embodiment, it may further comprise the steps:...

Embodiment 3

[0048] Preparation of construction residue mud pavement bricks

[0049] Ingredients: a building mud pavement brick, the raw material ratio is as follows in parts by weight: 350 kg of building mud, 170 kg of aggregate, 6 kg of curing agent, 70 kg of cement, and 90 kg of water.

[0050] The construction mud in this embodiment is a wet material or slurry obtained after simple dehydration and removal of sundries.

[0051] The aggregate in this embodiment is a fine aggregate with a particle size of 5-10 mm obtained after crushing, screening, and removing debris from construction waste.

[0052]The curing agent in this example is SIC soil curing agent dissolved in water at a ratio of 1:15 and then added.

[0053] The cement in this embodiment is Portland cement, sulphoaluminate cement, iron-aluminate cement or white cement.

[0054] The preparation method of building mud pavement brick in the present embodiment, it may further comprise the steps:

[0055] Mix and stir the constru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com