A welding method for single-sided welding and double-sided forming of a940 steel

A single-sided welding double-sided, welding method technology, applied in welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve the problems of high alloy composition, poor fluidity of the molten pool, etc., to ensure the inherent quality of the weld, The effect of satisfying the magnetic permeability and improving the fluidity of the molten pool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The single-sided welding and double-sided forming welding of the steel plate includes the following steps:

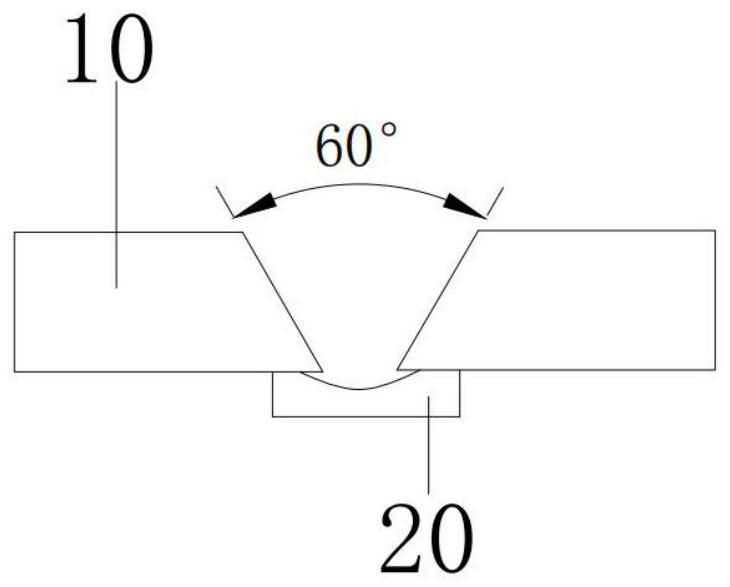

[0036] (1) The groove of A940 steel plate 10 should be processed by plasma cutting or carbon arc gouging. See the attached manual for the picture figure 1 .

[0037] (2) The gas shielded welding method is used for welding, using a welding machine with pulse function, the welding wire is 1.0mmA940MIG welding wire, and the shielding gas is 97.5% Ar+2.5% CO 2 Mixed gas, flow rate 25L / min.

[0038] (3) The welding direction adopts the left-hand method, and the temperature between passes is ≤100°C. After the slag removal of the bottom pass, it must be ground to reveal the metallic luster, and then the weld bead should be ground according to the slag removal condition.

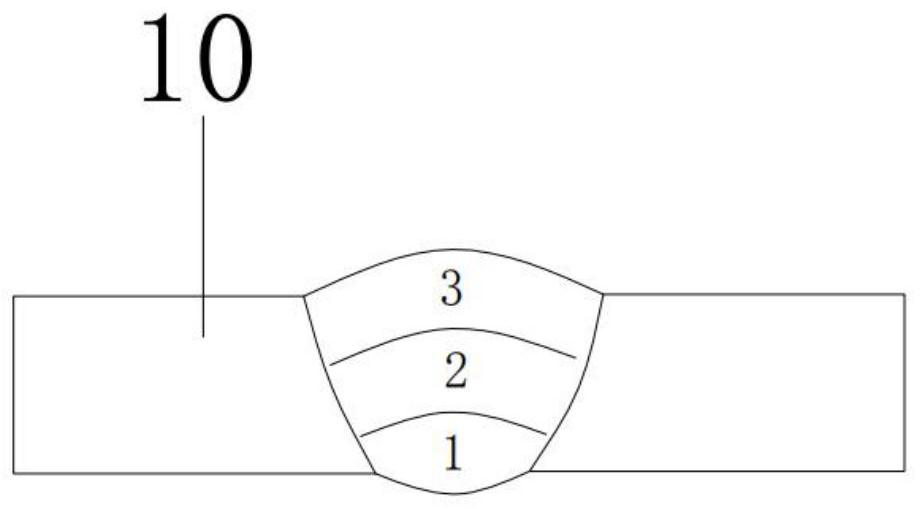

[0039] (4) The welding parameters are shown in Table 1 below, and the weld bead distribution and weld appearance dimensions are shown in the appendix of the manual. figure 2 .

[0040] Table 1 We...

Embodiment 2

[0045] In embodiment 2, only the shielding gas is changed to 99.9% Ar+0.1% CO2 mixed gas, all other test parameters are the same as embodiment 1, and the test welding is carried out.

Embodiment 3

[0047] In Example 3, only the shielding gas was changed to pure argon, and all other test parameters were the same as in Example 1, and the welding test was carried out.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com