Vision-based spherical fruit automatic grader

An automatic grading and fruit technology, applied in sorting, material analysis, material analysis through optical means, etc., can solve the problems of poor accuracy, low work efficiency, large floor space, etc., and achieve low manufacturing cost, simple structure, The effect of occupying a small area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

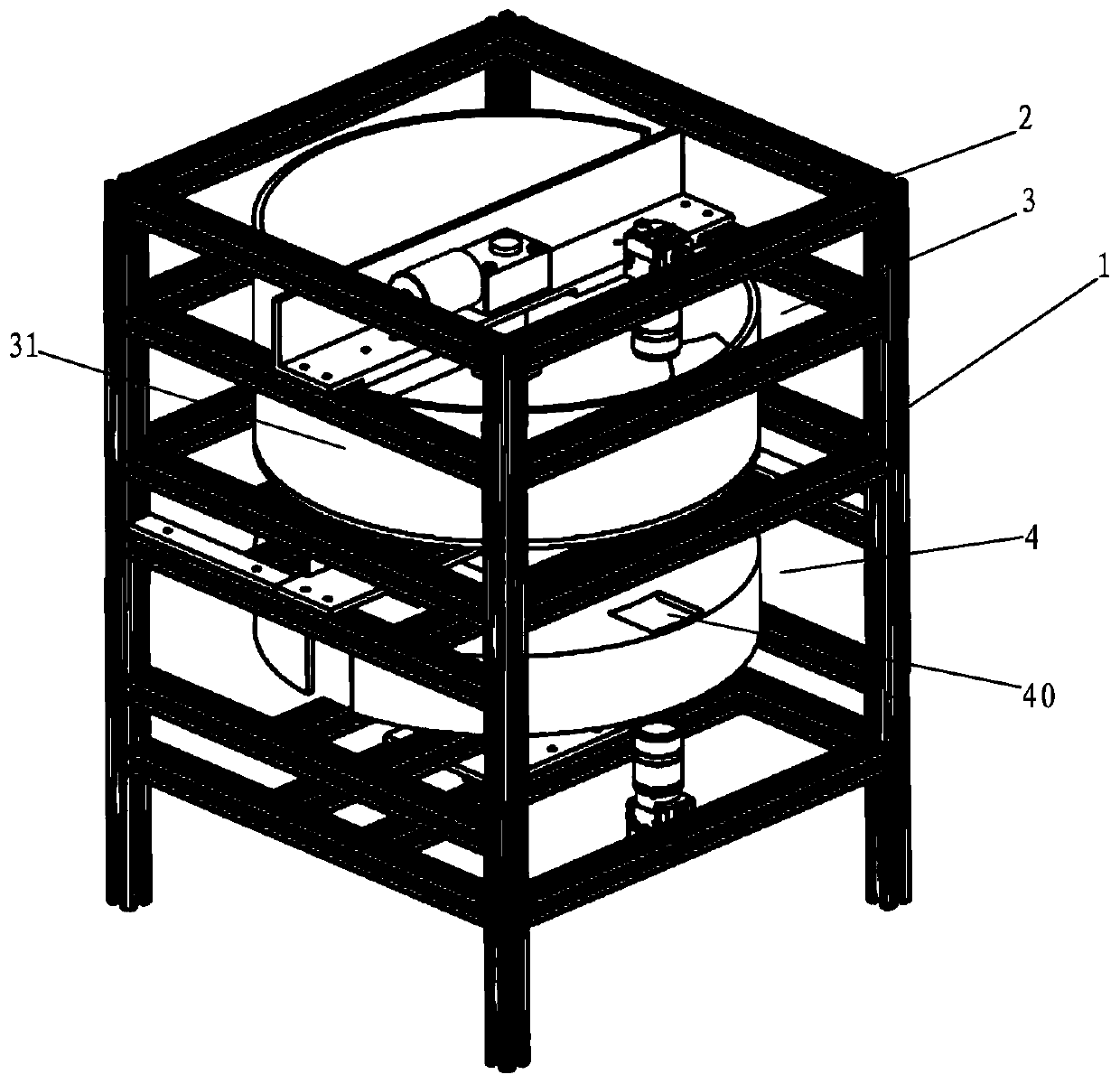

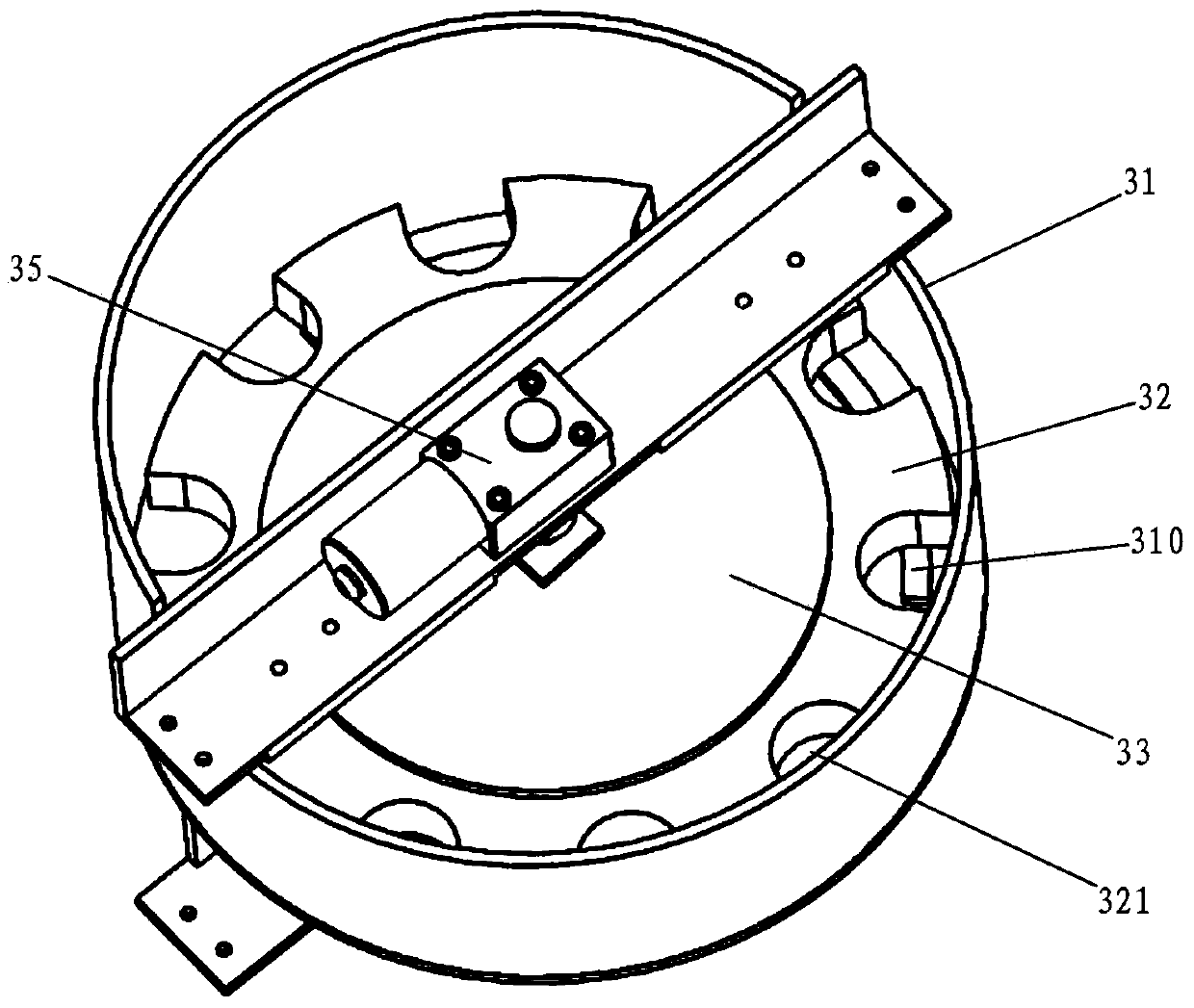

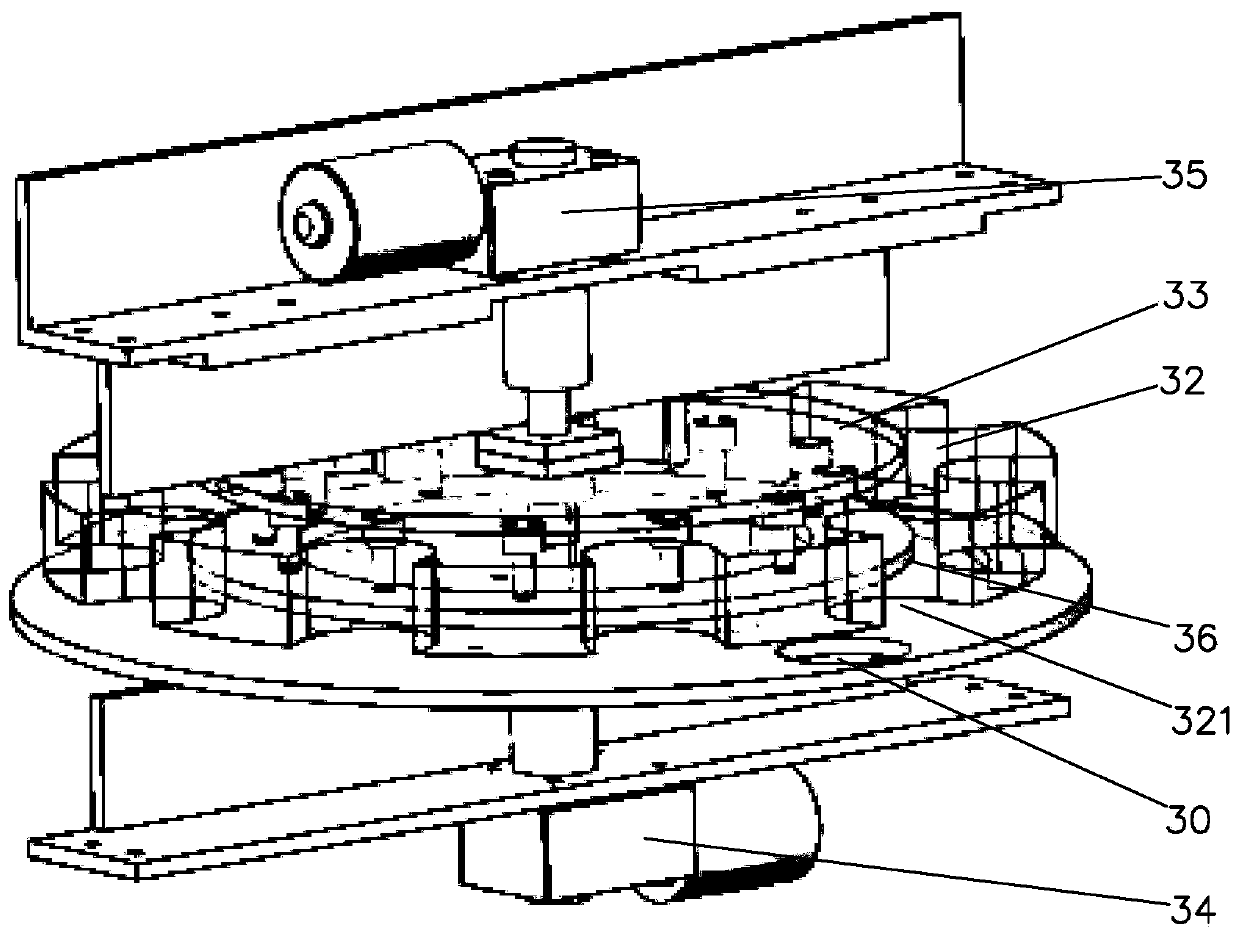

[0029] refer to Figure 1 to Figure 7 , the present embodiment relates to a vision-based spherical fruit automatic grading machine, including a frame 1, a detection device 2 installed on the frame 1, a monomer arrangement conveying device 3 and a grading execution device 4, and a detection device 2 for receiving data and control the controller 5 of the monomer arrangement conveying device 3 and the grading execution device 4, the detection device 2, the monomer arrangement conveying device 3 and the grading execution device 4 are distributed from top to bottom, and the monomer arrangement The fruit outlet 30 of the conveying device 3 communicates with the fruit inlet 40 of the classification execution device 4; the detection device 2 is arranged above the fruit outlet 30 to detect the surface information of the fruit, and the monomer arrangement conveying device 3 is used for The fruits are individually arranged and the fruits are transported to the fruit outlet 30 one by one....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com