A method of manufacturing a welding type heating device

A heating device and manufacturing method technology, applied in phototherapy, radiation therapy, treatment, etc., can solve problems such as production time delay, deformation, and increased defect rate of electronic characteristics, and achieve the effect of reducing failure and defect rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

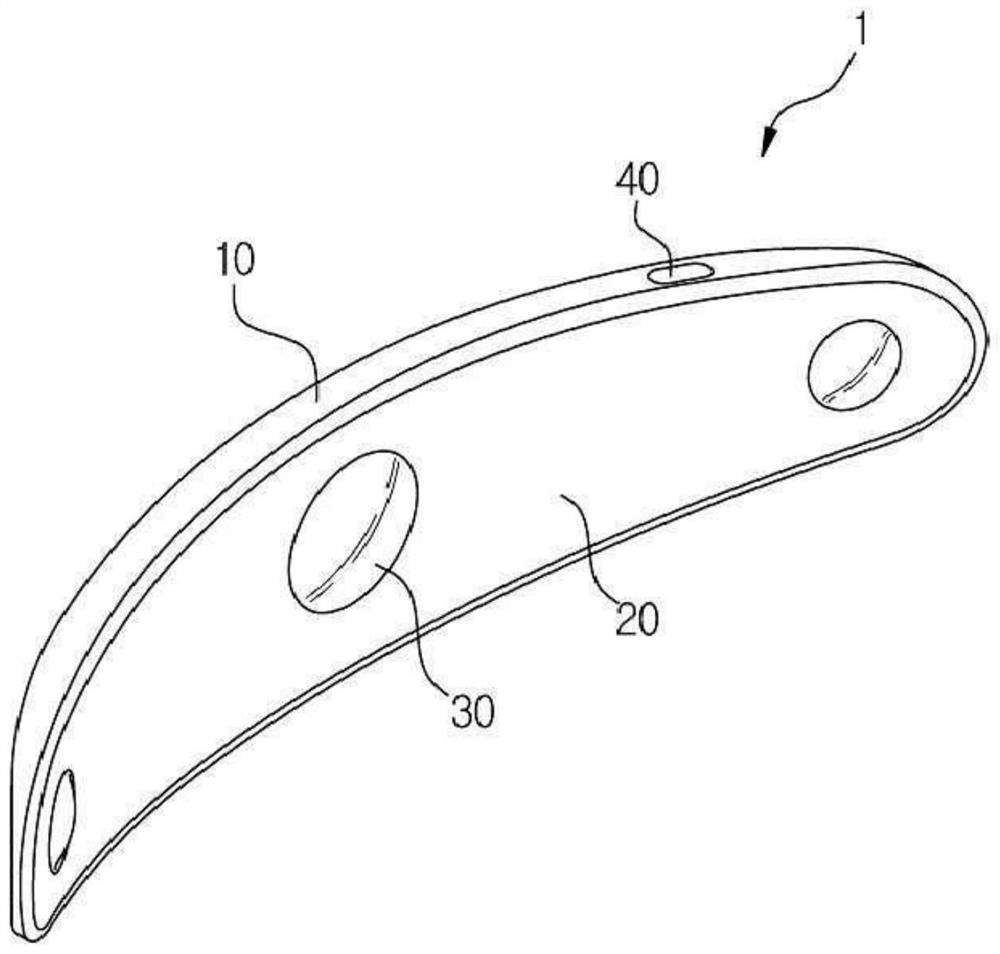

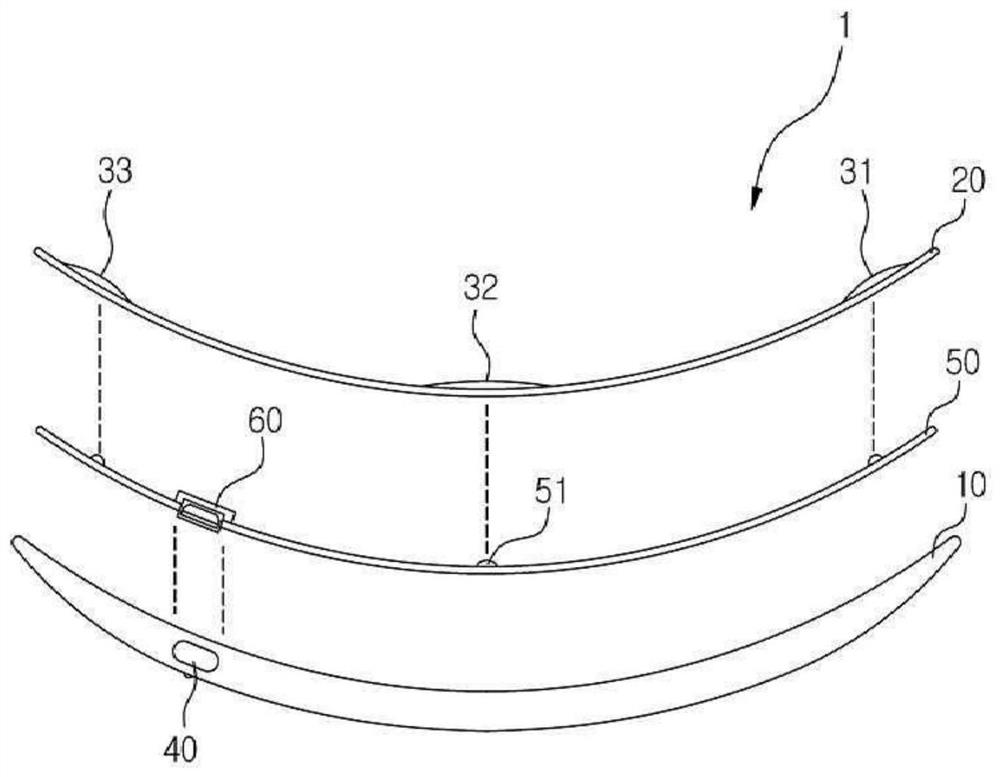

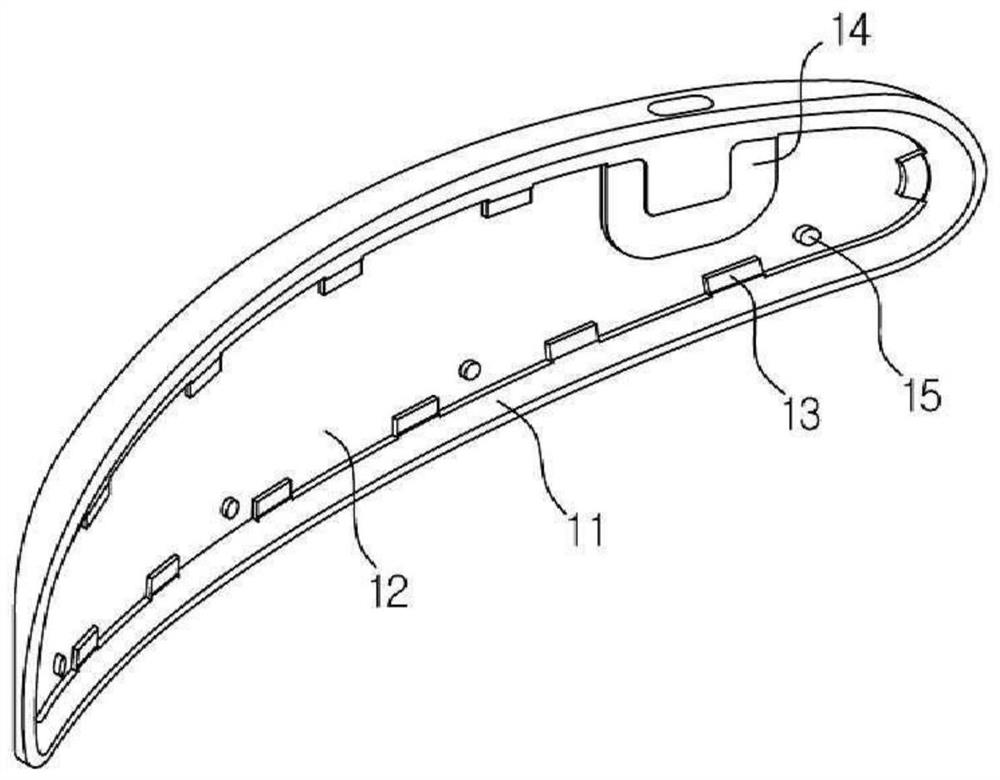

[0020] Hereinafter, specific implementation examples of the present invention will be described in detail with reference to the drawings. However, the concept of this invention is not limited to the following implementation examples, and practitioners who understand the concept of this invention can easily propose addition, modification, deletion, addition, etc. of constituent elements including other examples within the scope of the same concept. This is also included within the scope of the inventive concept.

[0021] In order to facilitate the understanding of the concept of the invention, the description of the overall structure in the accompanying drawings makes the specific parts such as the installation position different, and the same name is used in the case of the same function for easy understanding. When there are plural numbers of the same structure, only one structure will be described, and the same description will be applied to the other structures, and then th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com