Water injection device and method of an internal combustion engine

An internal combustion engine and water injection technology, applied in the field of water injection devices, can solve problems such as component function failure, filter clogging, and structural shedding, and achieve high economic efficiency, extend maintenance intervals, and avoid odors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

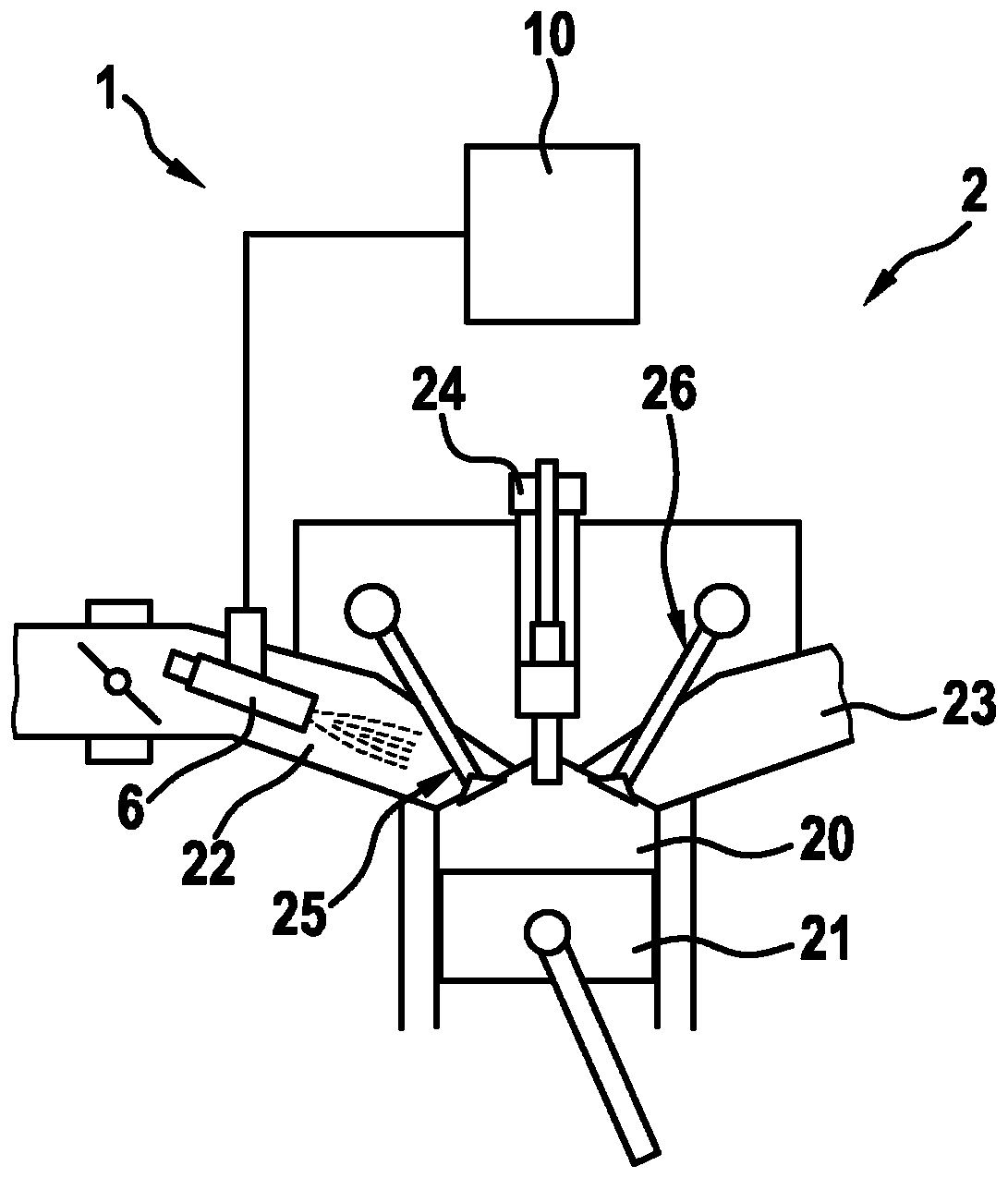

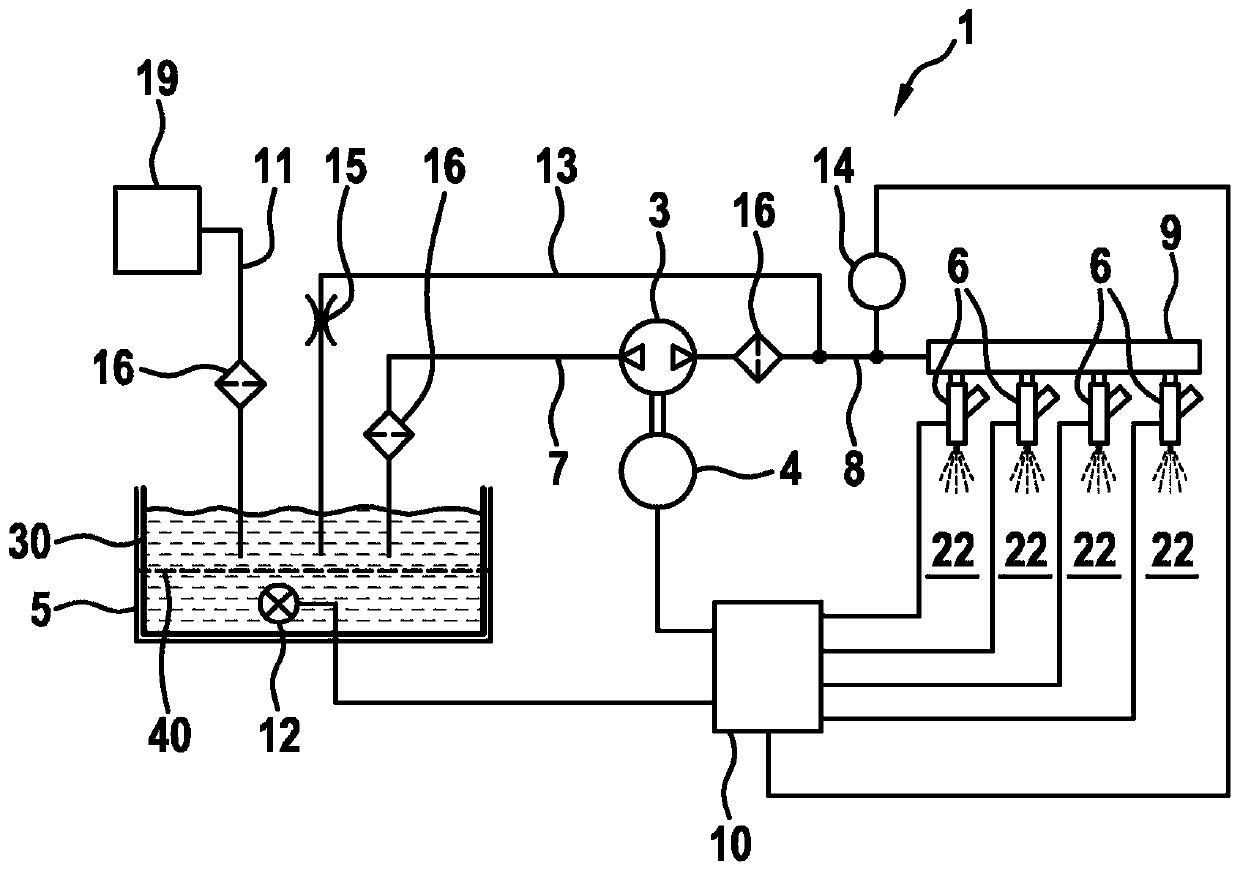

[0025] Refer below figure 1 and 2The device 1 for injecting water of the internal combustion engine 2 according to the first embodiment will be described in detail. The internal combustion engine 2 is operated in particular according to the Otto principle and with direct gasoline injection. Such an internal combustion engine is to be understood as an internal combustion engine in which the combustion of gasoline or a gasoline-air mixture is effected by ignition from an external source in the form of a spark plug. Since in such internal combustion engines the point of ignition is precisely predetermined by external ignition and the combustion is improved by water injection, a fail-safe operation of the internal combustion engine 2 is guaranteed by the use of cationic acid-forming metals and by the use of ultraviolet radiation for water purification Way.

[0026] exist figure 1 An internal combustion engine 2 is schematically shown in , which has a plurality of cylinders. E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com