Breaker having a wearing element and method for producing a wearing element of a breaker

A crusher and crushing cone technology, applied in grain processing and other directions, can solve the problems of necessary maintenance or replacement, reduced elongation at break, wear, etc., and achieve the effect of low manufacturing method and simple cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

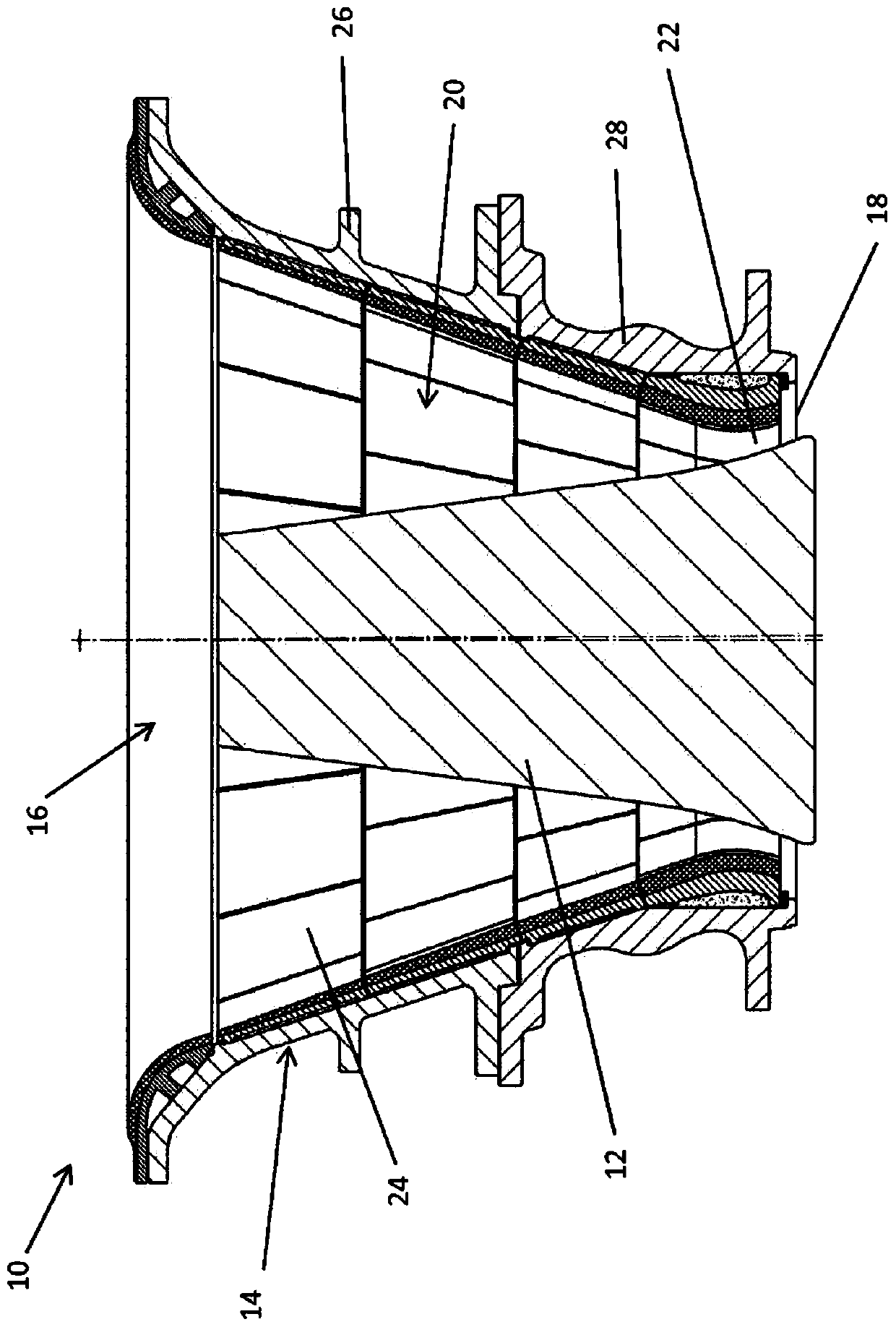

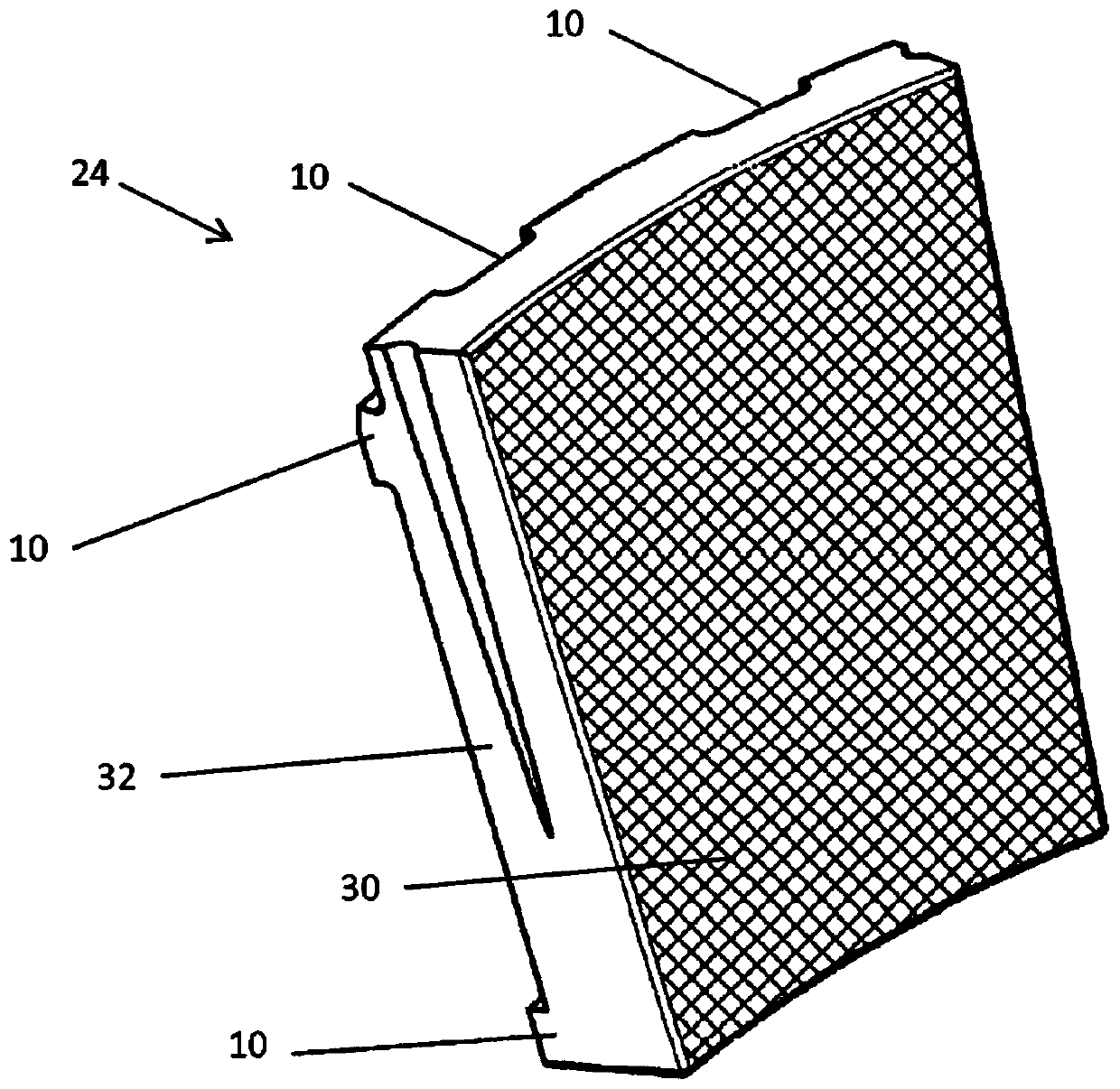

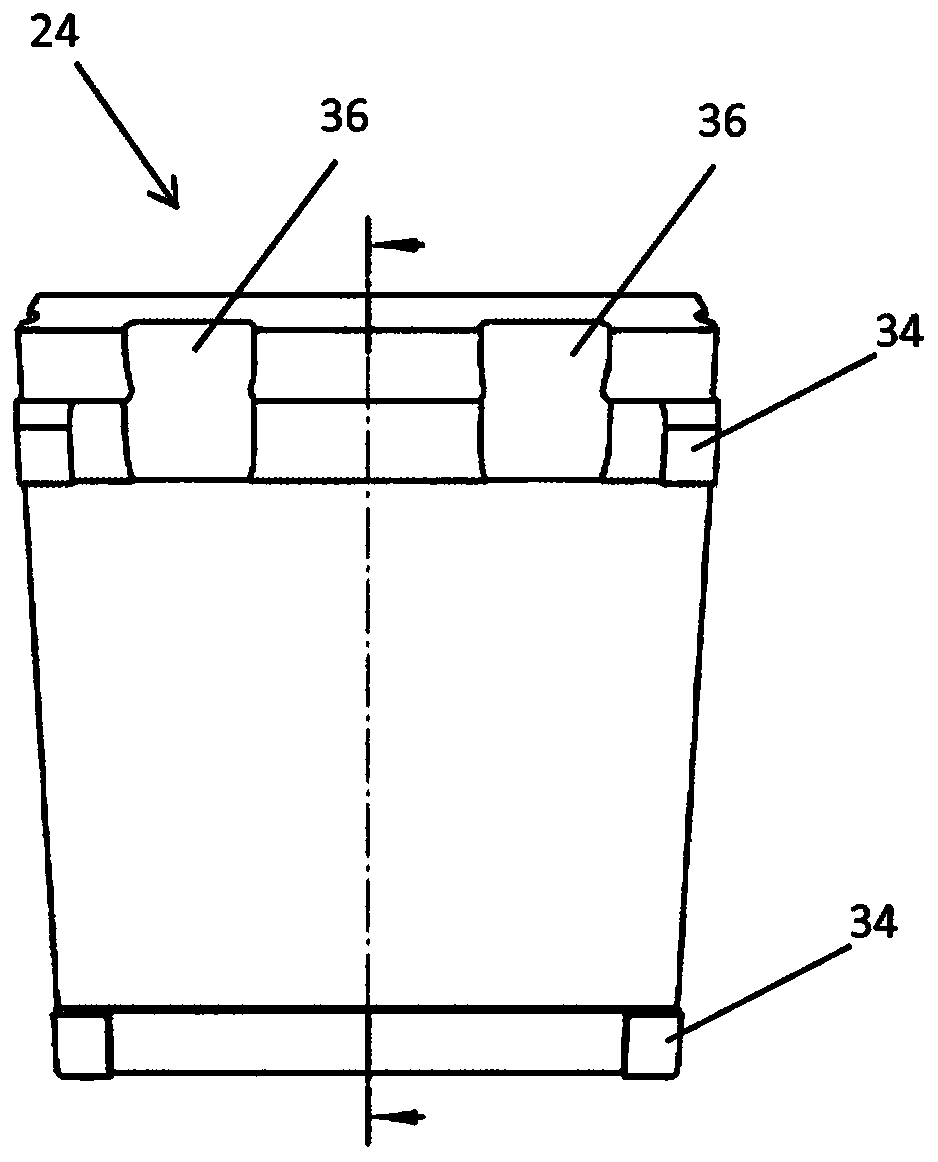

[0032] figure 1 A crusher 10 , in particular a gyratory crusher 10 , is shown with a movable crushing element, the crushing cone 12 , and a stationary crushing element, the crusher housing 14 . For the sake of simplification, for example, the drives, supports and funds of the gyratory crusher 10 are not shown. The gyratory crusher 10 is designed substantially rotationally symmetrically, the crusher housing 14 having the shape of a hollow cone and the crushing cone 12 is arranged in the hollow-conical crusher housing 14 . The crusher housing 14 has a feed area 16 into which the material to be shredded is fed. The feed area 16 is arranged on the upper side of the gyratory crusher 10 , and the crusher housing 14 has the largest diameter at the feed area 16 . The crusher housing 14 tapers in the axial direction from top to bottom, so that the lower region of the crusher housing 14 has the smallest diameter. The lower region of the crusher housing 14 forms an outlet 18 through w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com