Staggered stirring apparatus for producing instant powder, and using method thereof

A mixing equipment and staggered technology, which is applied in the field of staggered mixing equipment for the production of instant instant powder, can solve the problems of low mixing efficiency and achieve the effects of shortening mixing time, saving time, and avoiding waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

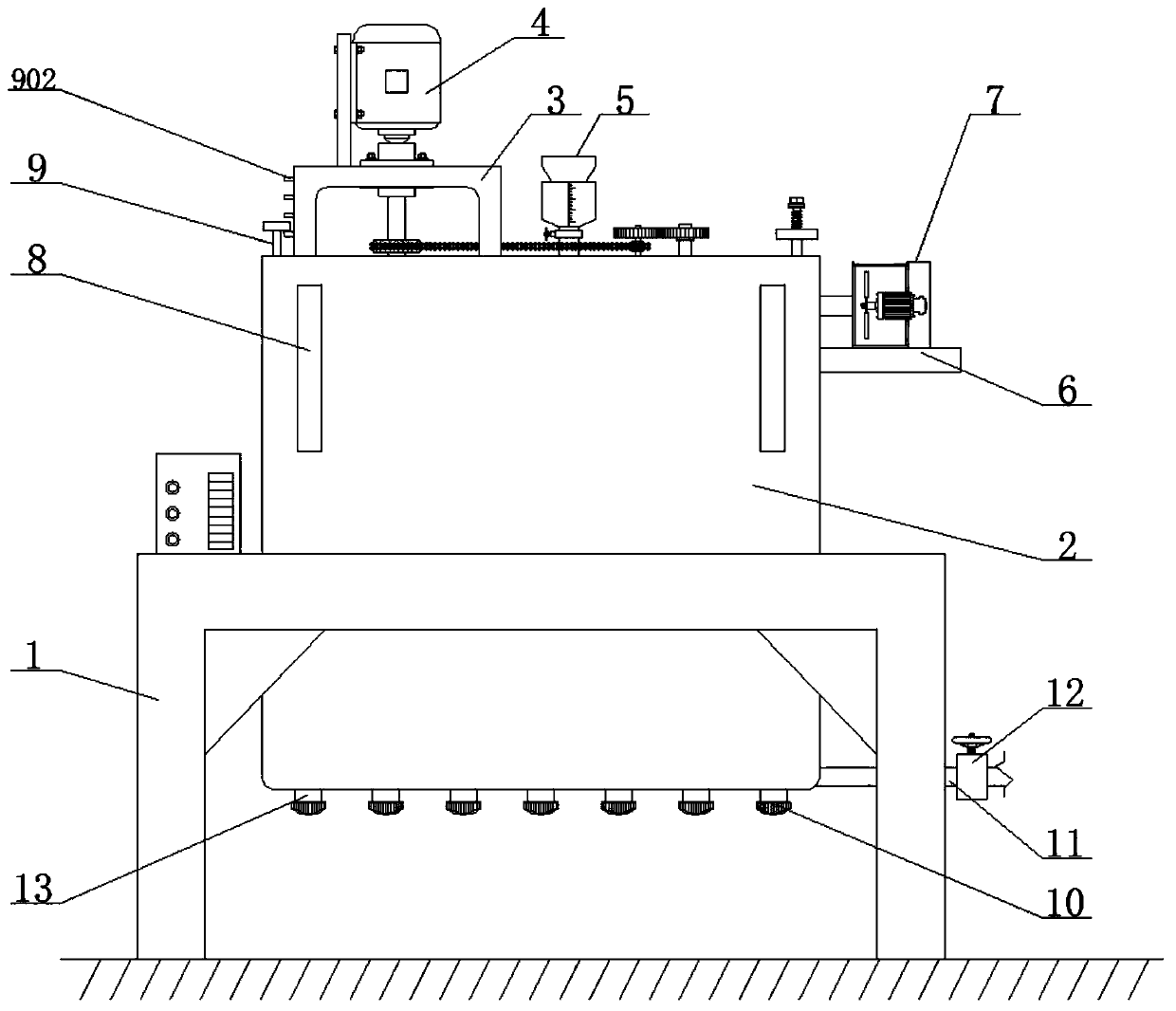

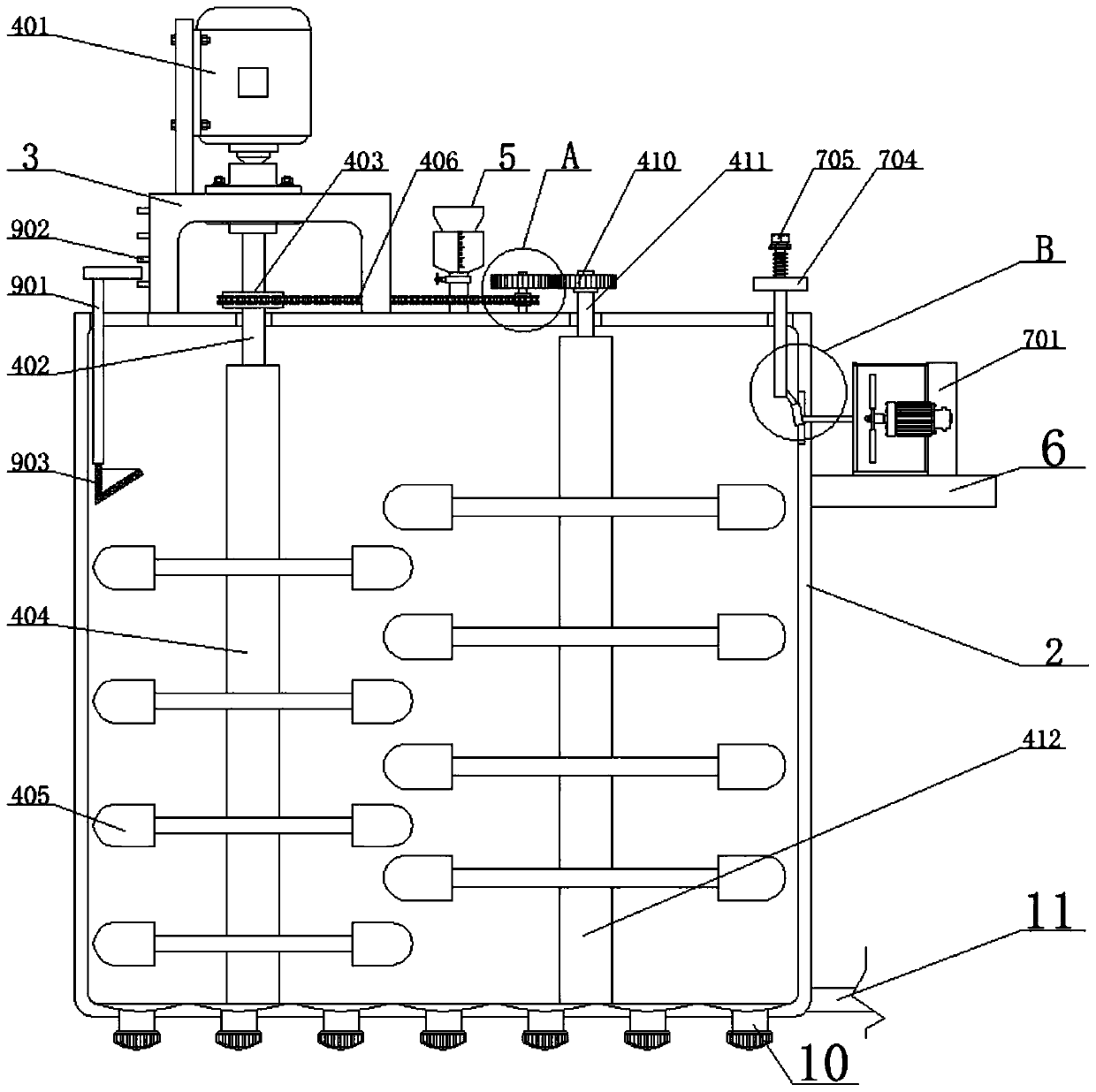

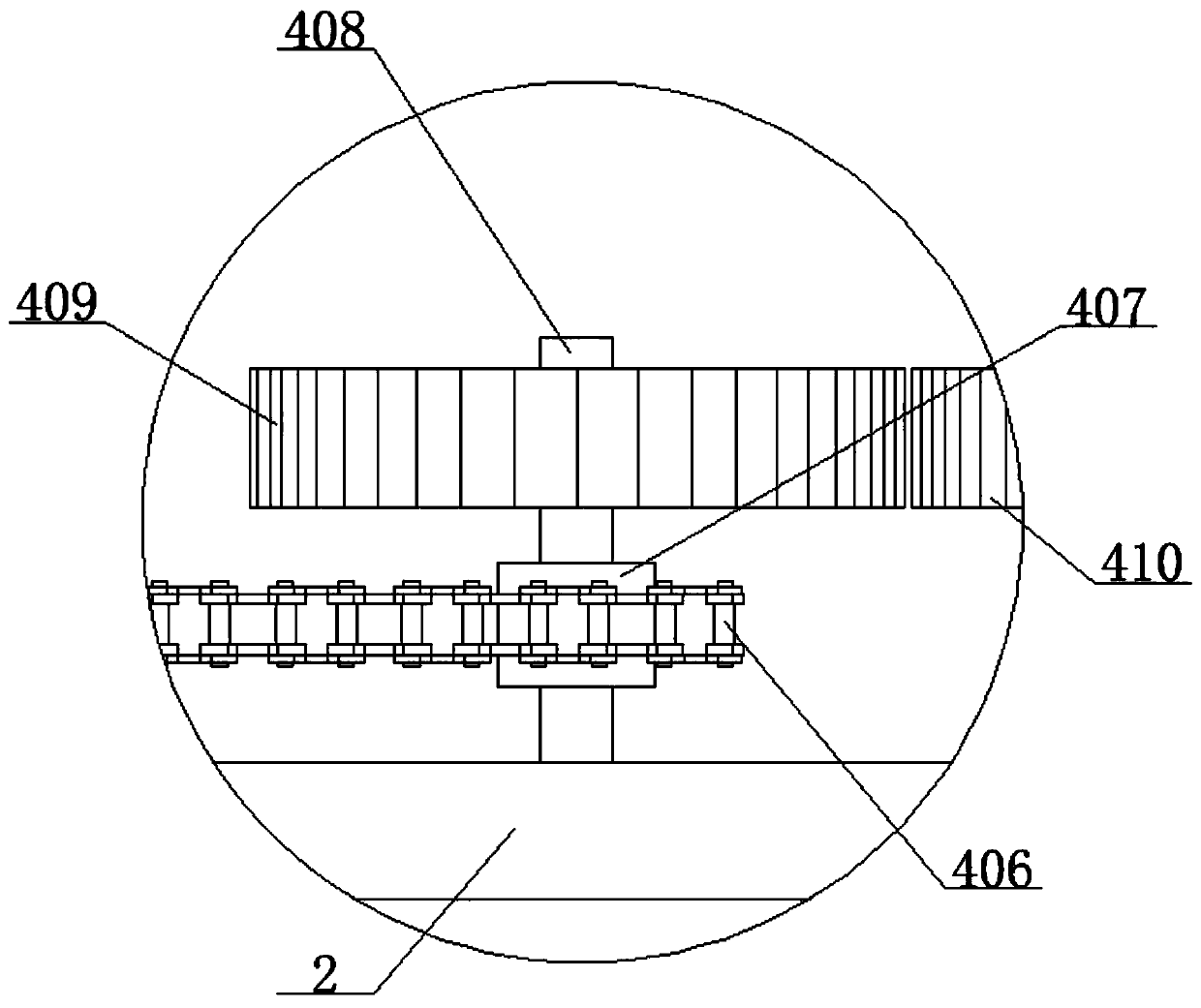

[0036] See figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 with Figure 8 , The present invention provides a technical solution:

[0037] A staggered stirring equipment for the production of instant instant powder and a use method thereof, comprising a support 1 and a stirring box 2. A stirring box 2 is fixedly connected to the inside of the support 1, and evenly distributed arc-shaped grooves are opened on the inner side of the lower end of the stirring box 2. In addition, a through pipe 13 is provided in the groove, and the lower end surface of the through pipe 13 is screwed with a sealing cover 10. This arrangement is convenient for removing the sediment by turning the sealing cover 10 after the work is completed, saving cleaning time. Observation board 8 It is composed of a transparent glass plate. This arrangement is convenient for people to observe the liquid level. The front end of the mixing box 2 is fixedly connected with an observation pla...

Embodiment 2

[0046] In embodiment 2, the same parts as in embodiment 1 will not be repeated. The difference is that this process is repeated. When batches of materials are mixed, the sealing cover 10 is rotated one by one to set the inner side of the lower end of the mixing box 3 The remaining sediment in the groove is discharged through the through pipe 13, and the cleaning can be realized by flushing with the water source. This arrangement facilitates the cleaning of the sediment, and makes it difficult for the sediment to flow into the next process with the material to ensure the quality of the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com