Efficient oil-water separation device for chemical engineering

An oil-water separation device and high-efficiency technology, applied in the direction of liquid separation, separation methods, chemical instruments and methods, etc., can solve the problems of low oil-water separation efficiency, inability to assist oil-water separation, and inability to accurately adjust the oil-water boundary line, etc., to improve The effect of oil-water separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

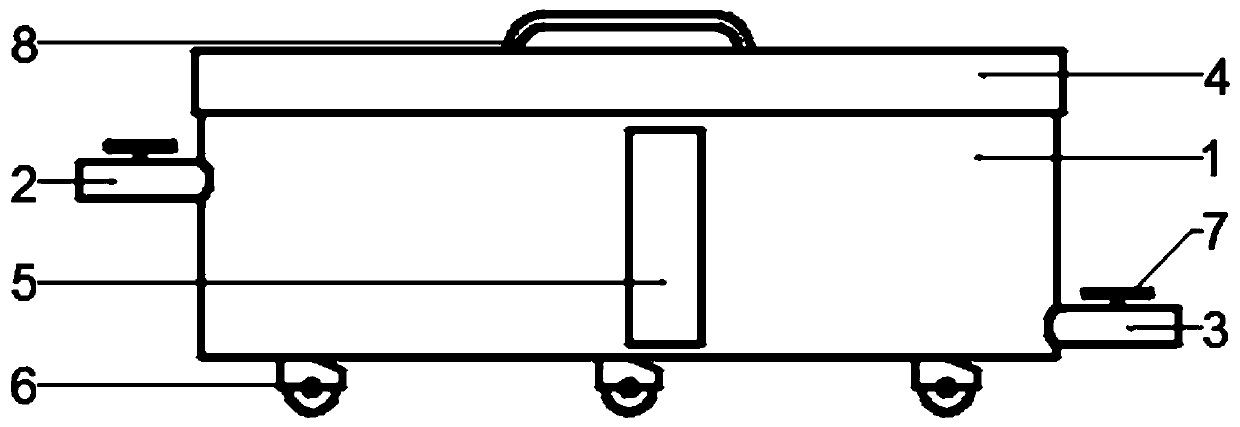

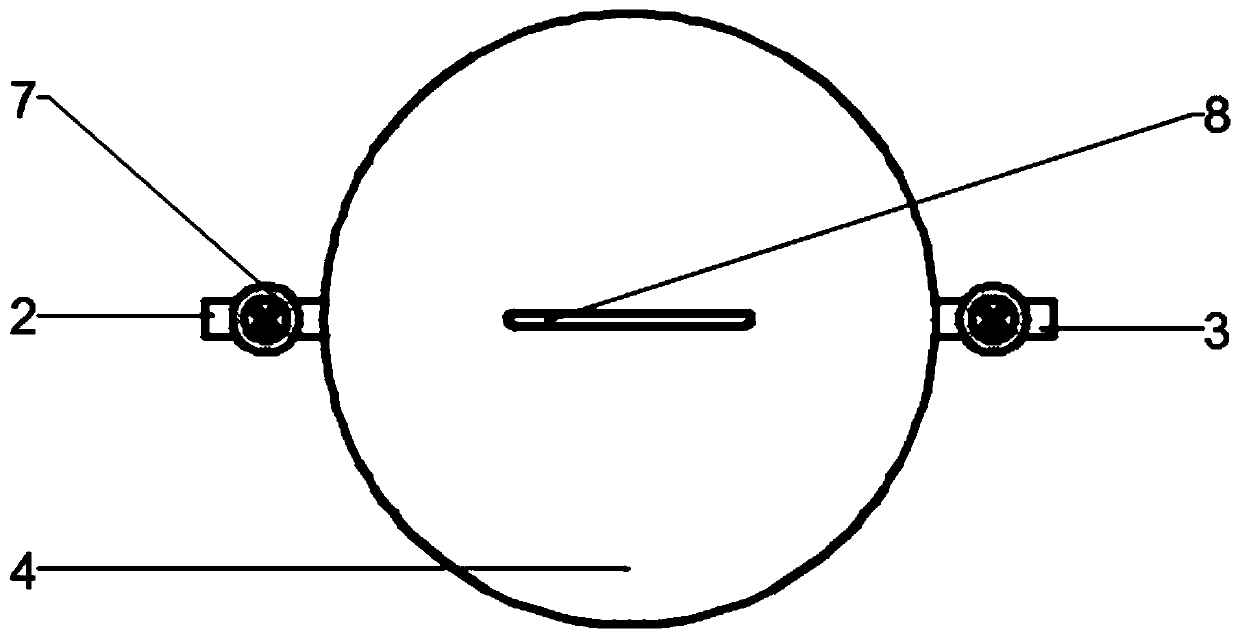

[0011] As shown in the figure, the high-efficiency oil-water separation device for chemical industry includes: separation barrel 1, oil discharge pipe 2 and drain pipe 3. The separation barrel 1, oil discharge pipe 2 and drain pipe 3 are all made of stainless steel, which is durable and corrosion-resistant Good performance, the separation barrel 1 is a cylinder, the top surface of the separation barrel 1 is provided with a bung 4, the surface of the bung 4 is provided with a handle 8, and the circumferential surface of the separation bucket 1 is longitudinally provided with an observation mirror 5, The observation mirror 5 is made of transparent tempered glass with high hardness and good light transmission. The observation mirror 5 is sealed and connected to the separation barrel 1 through a waterproof adhesive, and an oil discharge pipe is arranged on the upper end of the circumference of the separation barrel 1. 2. A drain pipe 3 is provided at the lower end, and both the oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com