Stator winding support

A stator winding and winding support technology is used in the manufacture of motor generators, electrical components, electromechanical devices, etc., which can solve the problems affecting the installation and use of motors, low production efficiency, and only manual operation, and achieve enhanced electrical insulation. performance, increased productivity, reduced damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

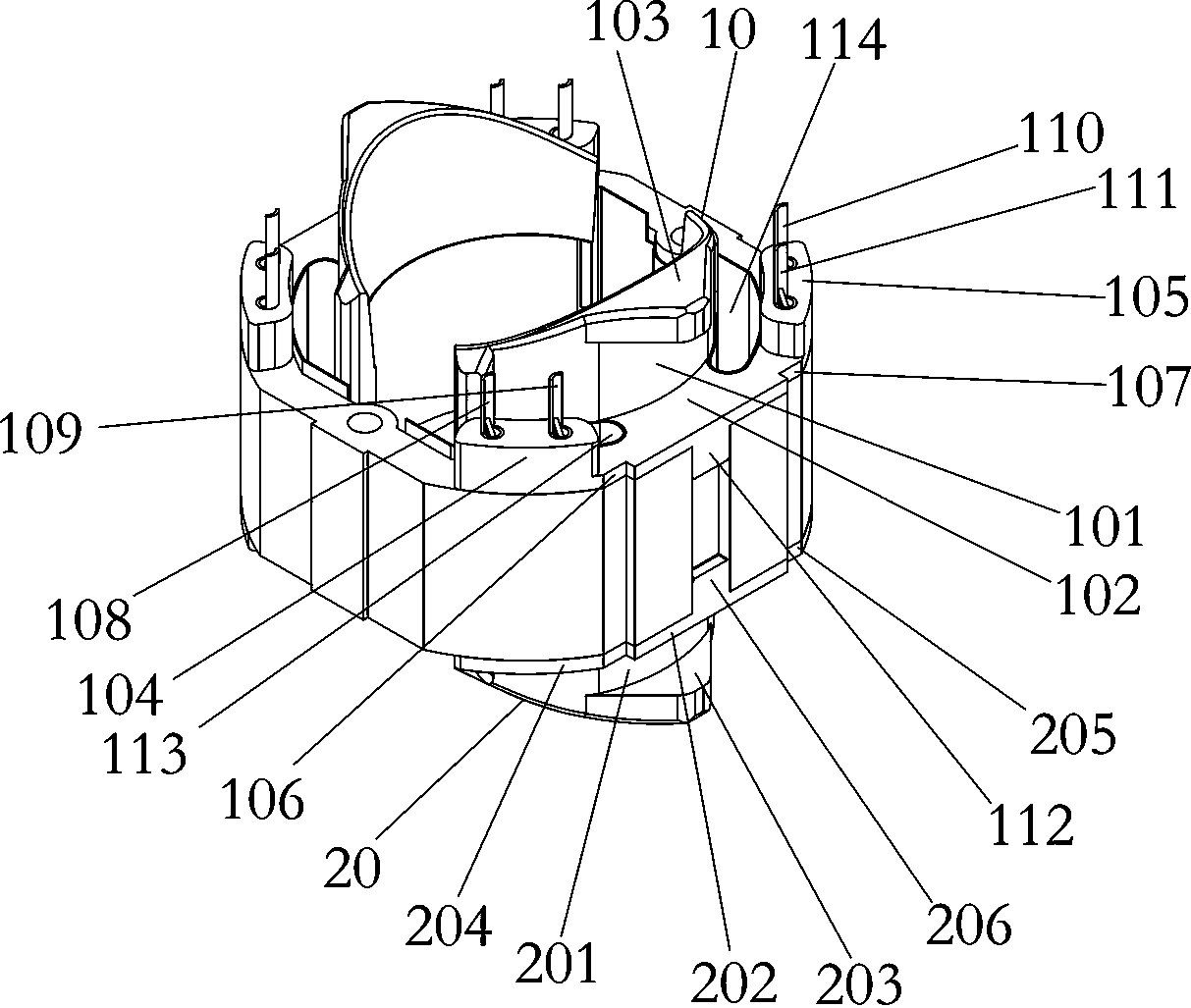

[0021] See figure 1 , a stator winding support of the present invention, comprising two opposite upper winding supports 10 and two opposite lower winding supports 20, the upper winding support 10 includes an upper arc portion 101, an upper horizontal portion 102, the upper limiting part 103 and the upper protrusions 104 and 105, the upper horizontal part 102 is provided in the middle of the outer wall of the upper arc part 101, and the two ends of the upper horizontal part 102 extend along the arc direction with upper extensions respectively. parts 106 and 107, an upper winding space 113 is formed between the upper extension part 106 and the upper arc part 101, and an upper winding space is formed between the upper extension part 107 and the upper arc part 114, the upper extension 106 is provided with the upper protrusion 104, the upper extension 107 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com