Method for rapidly determining ink stability

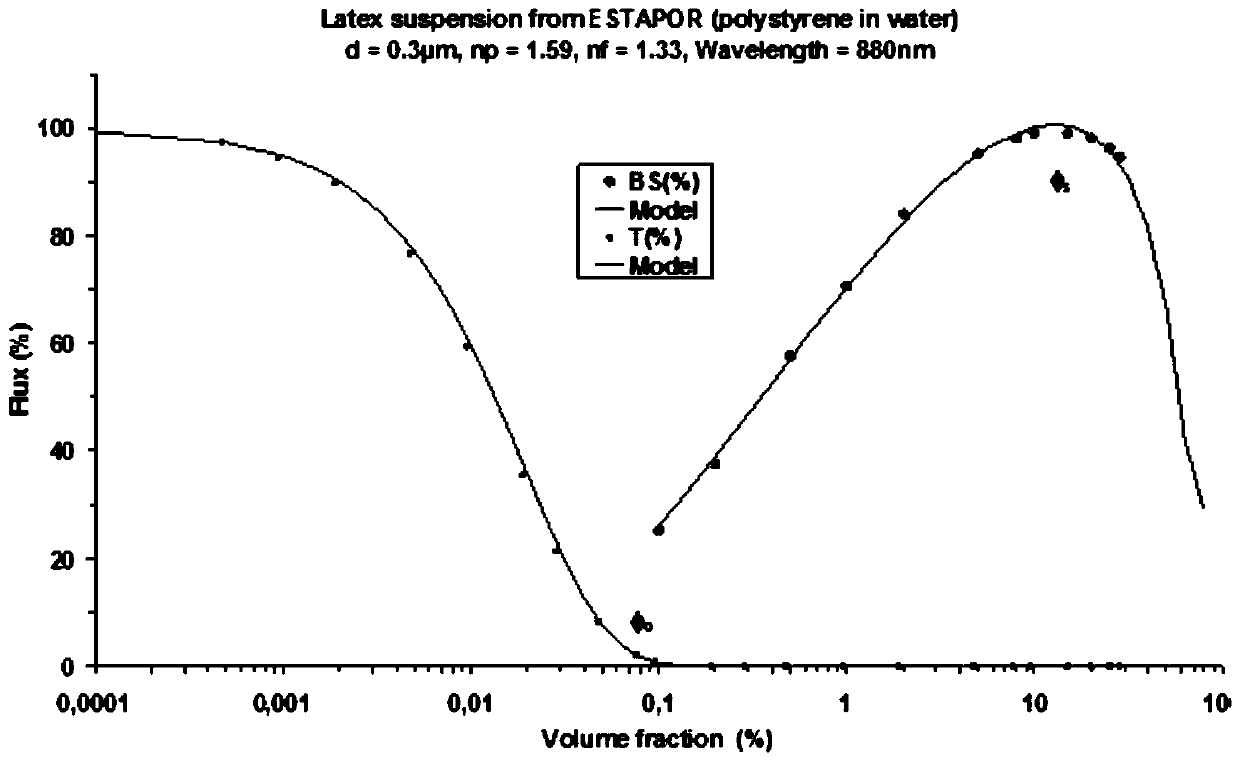

A rapid determination and stability technology, applied in measurement devices, scattering characteristics measurement, instruments, etc., can solve the problems of prolonging the ink development cycle, difficult to characterize and detect the evolution process of multiple dispersion systems, unable to observe the actual shape of the sample, etc. The effect of shortening the development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Example 1: High temperature storage time and stability parameters

[0061] The samples were placed in a 50°C electrothermal constant temperature incubator for different times, and their stability parameters were measured after returning to room temperature. The result is as Figure 8 shown. The results from the figure show that the change of ink can be significantly accelerated under high temperature storage at 50 °C. After about 29 days of high temperature storage, the stability parameters of the emulsified ink increased sharply, indicating that the stability of the emulsified ink has changed. Therefore, if the storage time at 50°C is set to more than 30 days, and the ink stability parameter has not changed, it indicates that it is still in a stable state, and the internal dispersed phase has no obvious change.

Embodiment 2

[0062] Example 2: Low temperature treatment and stability parameters

[0063] The samples were stored at -5°C for different times, and their stability parameters were determined after returning to room temperature. The result is as Figure 9 shown. It can be seen from the figure that after the emulsified ink is stored at -5℃ for different times, its stability parameters increase continuously with the extension of time, and show a relatively stable state within 6 days. After more than 6 days, the stability parameters increase sharply, indicating that the stability is greatly reduced. . Therefore, setting a storage time of 7 days can be used for the judgment of its long-term stability.

Embodiment 3

[0064] Example 3: Alternating Temperature Treatment and Stability Parameters

[0065] The samples were stored cyclically at -5°C and 50°C for 24h each time, that is, after being stored at -5°C for 24h, stored at room temperature for 24h, and then placed in a 50°C incubator for 24h, followed by cycles for several times and recovery. The stability parameters were determined after room temperature. The result is as Figure 10 shown. It can be seen from the figure that the high and low temperature alternating storage experiments have obvious effects on the stability. The emulsified ink shows good stability after one alternating storage, but its stability decreases significantly after two alternating treatments. After 3 times of alternating treatment, the stability decreased more obviously. Therefore, 3 times of alternating high and low temperature is set as the standard for stability evaluation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com