Small and minitype household garbage gasifier

A domestic waste and gasification furnace technology, applied in incinerators, combustion types, indirect carbon dioxide emission reduction, etc., can solve the problems of high thermal ignition loss rate of ash and slag, complex flue gas composition, and unstable combustion in the secondary combustion chamber. Achieve the effects of reducing the load and cost of flue gas treatment, improving the comprehensive incineration effect, and eliminating the inclusion of pyrolysis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

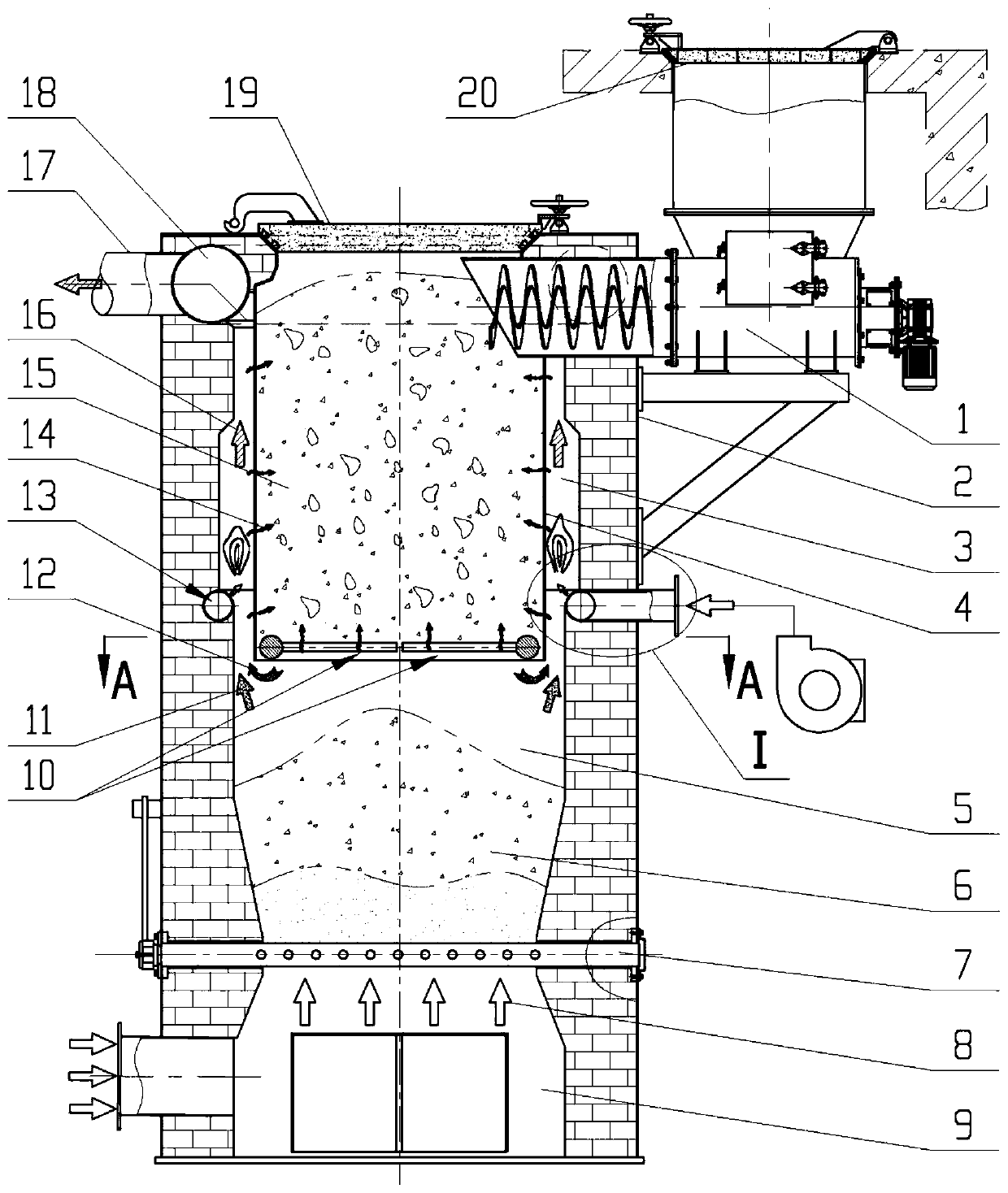

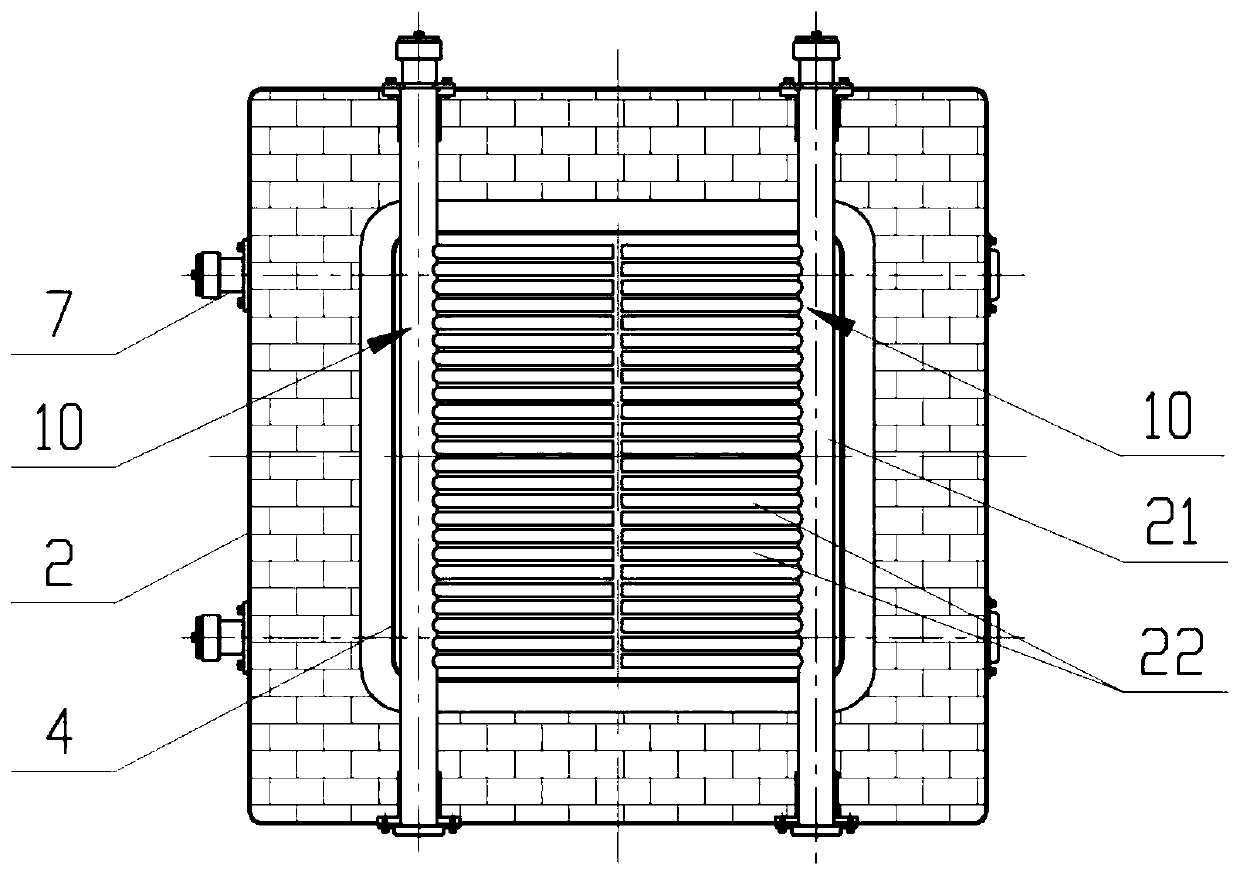

[0041] A kind of small miniature house refuse gasifier, refer to attached Figure 1-4 , comprising a body of furnace 2, the interior of the body of furnace 2 is provided with a grate 7, and the grate 7 divides the inner cavity of the body of furnace 2 into upper and lower parts, the upper part is the furnace 5, and the lower part is the ash chamber 9. The upper part of the furnace body 2 is provided with a feeding system 1 with a lock valve 20 and a smoke exhaust pipe 17, and the furnace 5 is provided with a gasification kettle 4, and the outlet of the feeding system 1 is in the gas The inside of the gasification kettle 4, the top of the gasification kettle 4 is provided with an inspection door 19 that can pass through the furnace; an annular air flow passage is left between the outer wall of the gasification kettle 4 and the inner side of the furnace 5, that is, the second combustion District 3, the bottom is provided with a discharge door 10; the lower part of the secondary ...

Embodiment 2

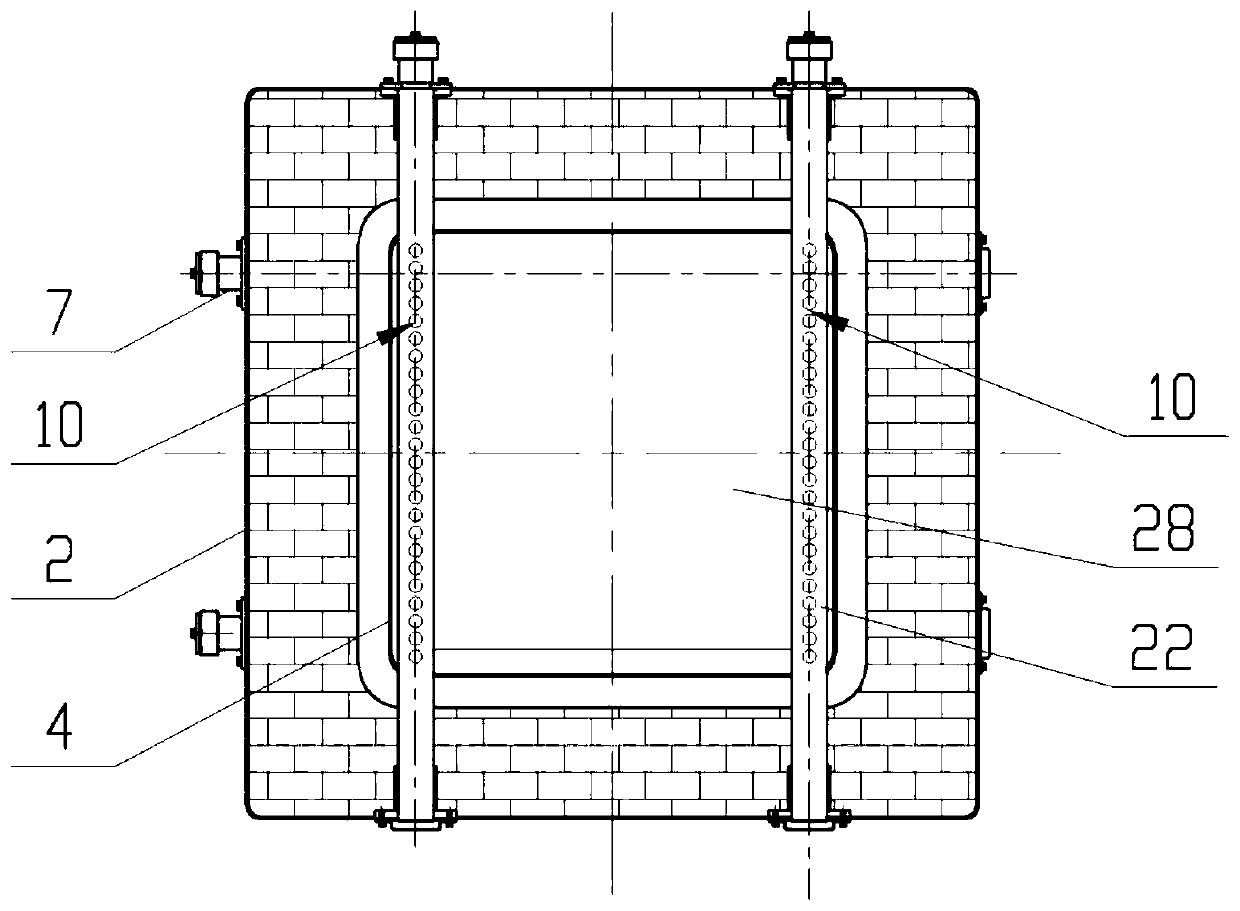

[0046] Embodiment two, referring to the attached Figure 1-3 and 5, the difference between the second embodiment and the first embodiment is that the structure of the secondary air supply system 13 has another possible structure, in figure 1 combined on the basis of Figure 4 , the annular pipe 24 is located outside the body of furnace 2, and is provided with a secondary air inlet pipe 25 communicating with it and a certain number of manifolds 27, and the manifolds 27 all pass through the body of the furnace 2. The side wall extends into the secondary combustion zone 3, and an air supply hole 23 leading to the secondary combustion zone 3 is opened on it; the secondary air 26 can enter the replacement tube 24 from the secondary air inlet pipe 25, and then pass through the manifold respectively 27, enter the secondary combustion zone 3 from the air supply hole 23.

[0047] With the above-mentioned structure, when the incinerator feeds, the air lock valve 20 on the feeding syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com