A high-precision conveying device suitable for ultra-high pressure dual-degree-of-freedom series coordination

A technology of conveying device and degrees of freedom, applied in the direction of transmission, transmission parts, gear lubrication/cooling, etc., can solve the problems of loss of transmission accuracy, large axial deformation of the plunger, complex transmission links, etc., to reduce the loss of precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further explained and illustrated below in conjunction with the accompanying drawings and specific embodiments.

[0032] A high-precision conveying device suitable for ultra-high pressure dual-degree-of-freedom series coordination,

[0033] A high-precision conveying device suitable for ultra-high pressure dual-degree-of-freedom series coordination, detailed as follows:

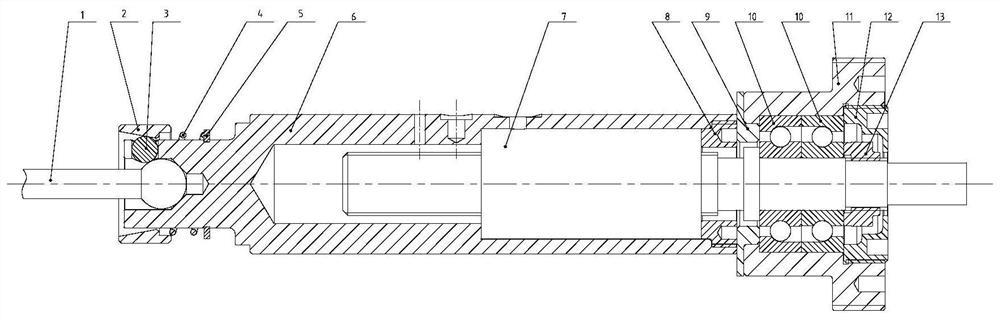

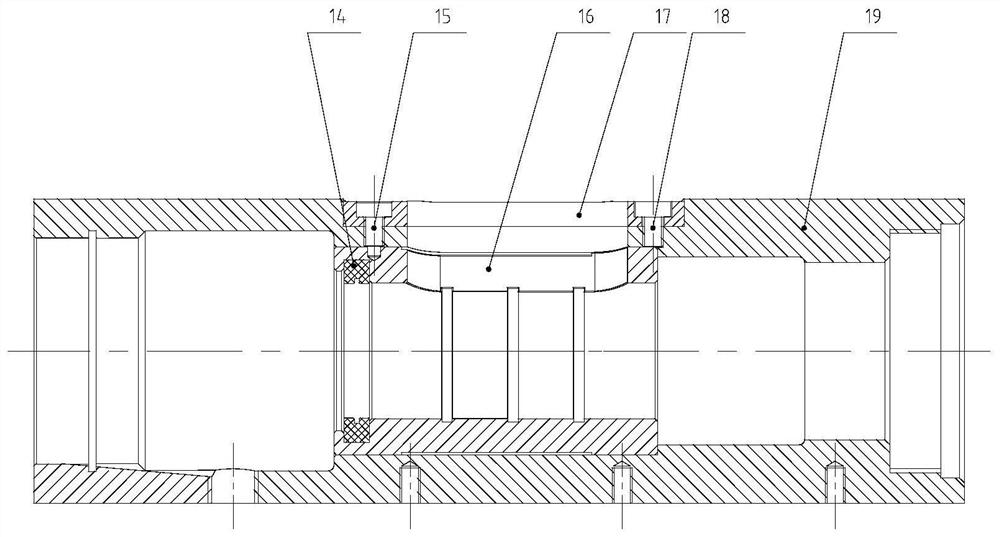

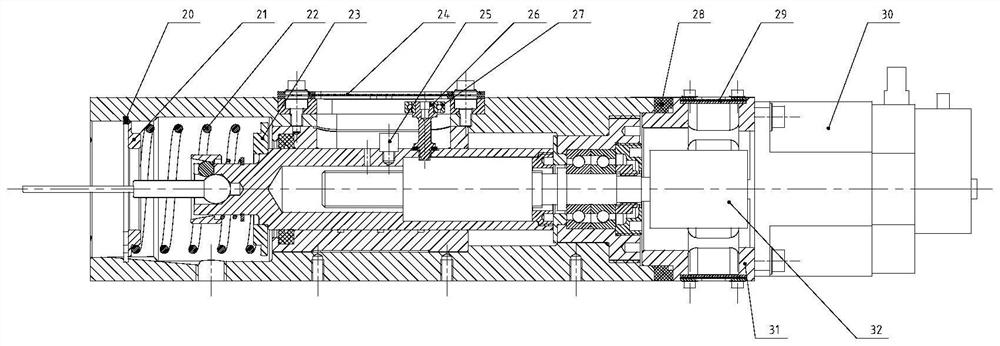

[0034] (1) A high-precision conveying device suitable for ultra-high pressure dual-degree-of-freedom series coordination is used to realize the reciprocating motion of the plunger rod, which is realized by the driving part and high-precision ball screw, and the ball screw pair uses the screw to rotate , the way the nut reciprocates, the reciprocating movement of the nut drives the plunger rod to reciprocate. It mainly includes: driving parts, transmission shaft system, constant temperature housing and buffer parts, etc. The driving part includes a motor and an encoder, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com