Material distribution method for blast furnace opening

A blast furnace and cloth technology, applied in blast furnaces, blast furnace details, furnaces, etc., can solve the problems of slag and iron not being discharged smoothly, poor furnace opening, and high slag material.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

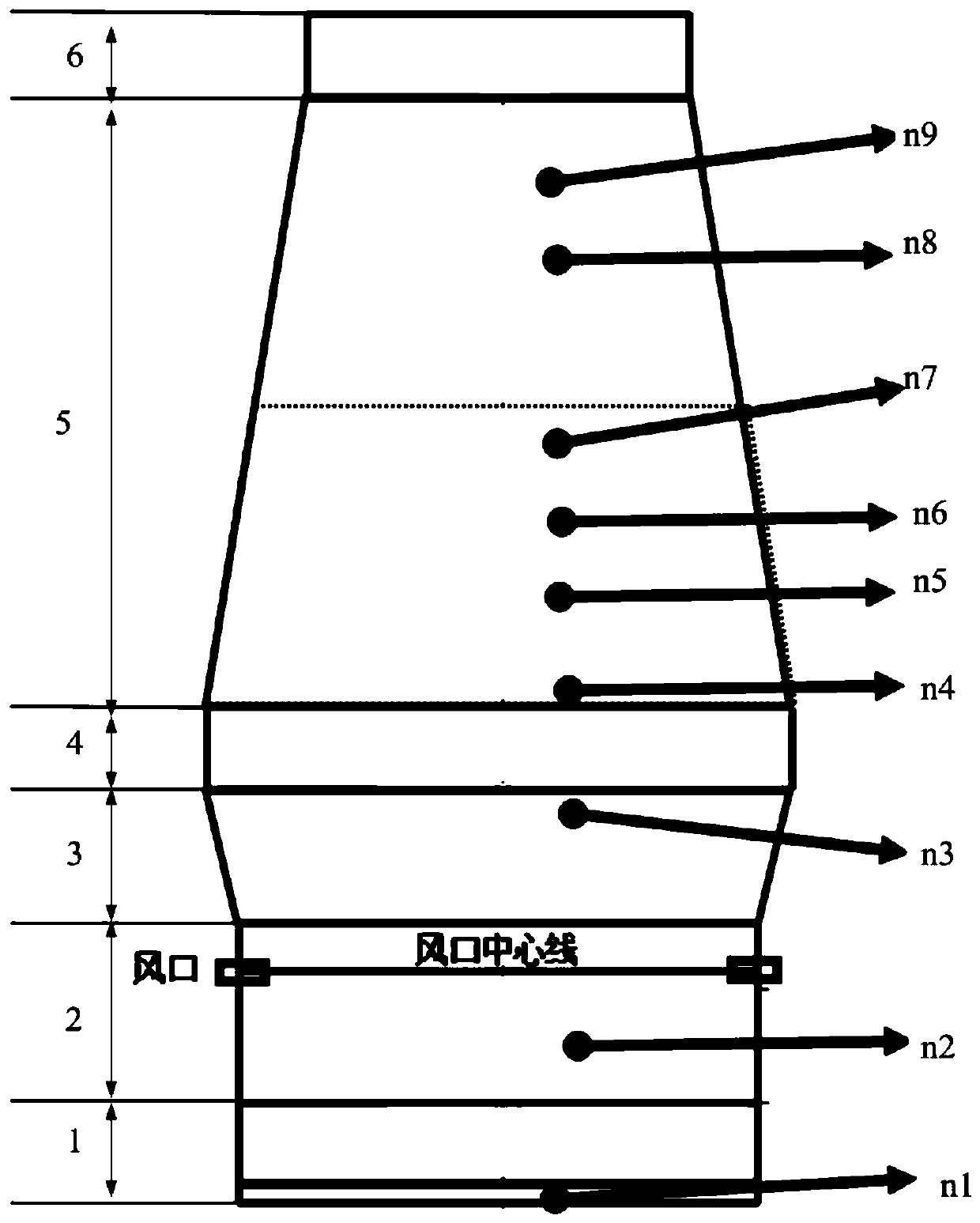

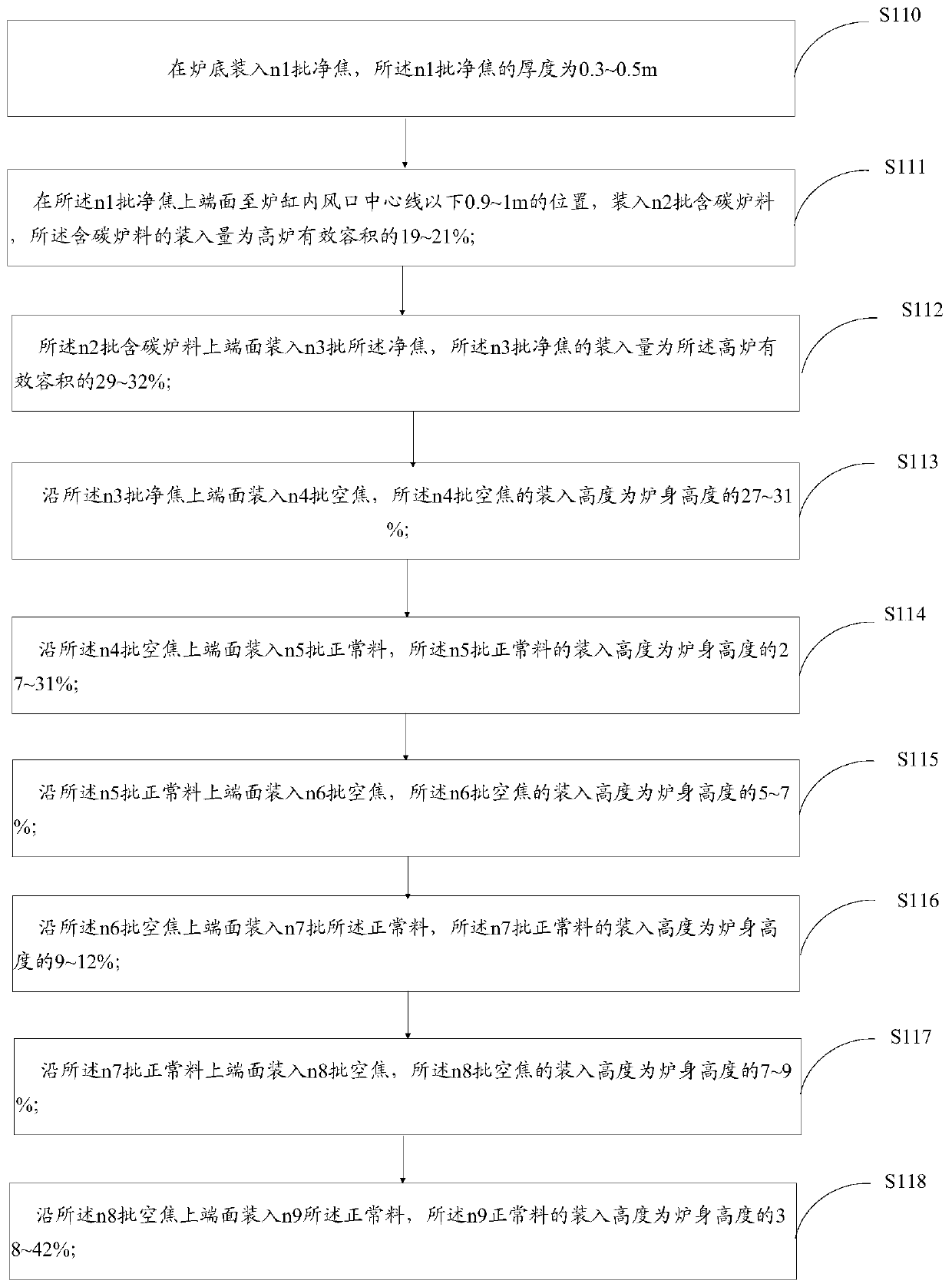

[0028] This embodiment provides a method for distributing materials for blast furnace opening, which is applied in a blast furnace. In order to better understand the technical solution of this application, refer to figure 1 , the blast furnace includes from bottom to top: furnace bottom 1, furnace hearth 2, furnace bosh 3, furnace waist 4, furnace body 5 and furnace throat 6; the center line of blast furnace tuyere is located on the upper edge of furnace hearth 2, as figure 2 As shown, the method includes:

[0029] S110, loading n1 batches of clean coke at the bottom of the furnace, the thickness of the n1 batches of clean coke being 0.3-0.5m;

[0030] Load n1 batches of clean coke into the bottom of the furnace, the thickness of the n1 batches of clean coke is 0.3-0.5m; the function of the clean coke here is to protect the bottom coke, mainly for protecting the castable at the bottom of the furnace. The value of n1 can be determined according to the actual situation.

[00...

Embodiment 2

[0055] In practical application, for 5500m 3 When the blast furnace is opened and the material is distributed, the specific implementation is as follows:

[0056] The first layer: 2 batches of clean coke are loaded into the bottom of the furnace with a thickness of 0.49m.

[0057] The second layer: From the upper end of the first layer of clean coke to the position 1m below the center line of the tuyere in the furnace hearth, n2 batches of carbon-containing charge are loaded, and the charge amount of carbon-containing charge is 20% of the effective volume of the blast furnace. In this embodiment, the carbon-containing charge is hard miscellaneous wood.

[0058] The third layer: 28 batches of clean coke are loaded along the upper end surface of the carbon-containing charge of the second layer, and the charging amount of the 28 batches of clean coke is 30.2% of the effective volume of the blast furnace;

[0059] The fourth layer: 18 batches of empty coke are loaded along the u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com