Multi-stage temperature-control ventilation production method of multi-microorganism high-temperature bacterial fragrant koji

A production method and bacterial technology, applied in the field of brewing, can solve the problems of single culture mode but not multi-stage, multiple temperature control methods and precise temperature control and ventilation culture, so as to ensure the production and accumulation of metabolic aroma substances and improve economic efficiency. Benefits, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

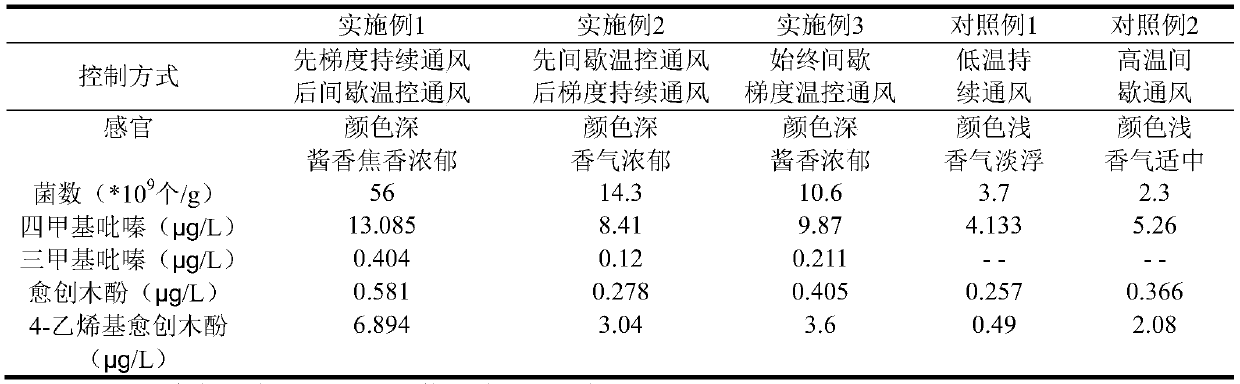

Embodiment 1

[0032] Embodiment 1: produce multi-micro high-temperature bacteria fragrant song

[0033](1) Preparation of high-temperature bacterial seed liquid: first, Bacillus subtilis (CCTCC AB 130016, CGMCC No.1.934), Bacillus licheniformis (CCTCC AB 91060, CGMCCNo. 1.813), Bacillus coagulans (CGMCC No.1.3220, CGMCC No.1.2407), Bacillus amyloliquefaciens (CGMCC No.1.1414, CGMCC No.1.398), Paenibacillus polymyxa (CGMCC No.1.2979), Bacillus circulans ( CCTCCAB 207844) totally 10 strains of high-temperature bacteria were activated on a slant, followed by respectively taking a ring of bacteria after activation and carrying out pure-blooded liquid culture in beef extract peptone liquid medium (300mL / 500mL) with a pH value of 6.5, the shaking table speed was 85r / min, The temperature is 40°C, cultivated for 20 hours, and the pure high-temperature bacterial seed solution is obtained, and the number of bacterial cells per milliliter is kept at 10 8 A / mL or so;

[0034] (2) Preparation of polym...

Embodiment 2

[0046] Embodiment 2: produce the fragrant song of many microthermia bacteria

[0047] (1) Preparation of high-temperature bacterial seed liquid: first, Bacillus subtilis (CCTCC AB 130016), Bacillus licheniformis (CCTCC AB 91060, CGMCC No.1.813), coagulation Bacillus (CCTCC AB 92066, CGMCC No.1.3220), Bacillus amyloliquefaciens (CGMCC No.1.257), and Bacillus circulans (CCTCC AB 207850, CCTCC AB 207844) were used for slant activation. The activated one-ring bacteria were cultured in a pure-bred liquid medium (300mL / 500mL) with a pH value of 6.5 in beef extract peptone medium, at a shaking table speed of 85r / min, at a temperature of 40°C, and cultivated for 20 hours to obtain a pure-bred high-temperature bacterial seed solution , the number of cells per milliliter was kept at 10 8 A / mL or so;

[0048] (2) Preparation of polymicrothermic bacteria liquid: ① firstly, prepare secondary and tertiary fermenter culture medium with 0.7% glucose, 0.8% maltose, 1% peptone and 0.6% yeast ...

Embodiment 3

[0052] Embodiment 3: produce the fragrant song of many microthermia bacteria

[0053] (1) Preparation of high-temperature bacterial seed liquid: first, Bacillus subtilis (CCTCC AB 130016, CGMCC No.1.934), Bacillus licheniformis (CCTCC AB 91060, CGMCCNo. 1.813), Bacillus coagulans (CCTCC AB 92066, CGMCC No.1.3220, CGMCC No.1.2407), Paenibacillus polymyxa (CGMCC No.1.2979), Bacillus amyloliquefaciens (CGMCC No.1.1414, CGMCC No.1.257) Circulus, Bacillus circulans (CCTCC AB 207850, CCTCC AB 207844), a total of 12 strains of high-temperature bacteria were activated on the slant, and then a circle of activated bacteria were purified in beef extract peptone liquid medium (300mL / 500mL) with a pH value of 6.5. Seed liquid culture, shaking table speed 85r / min, temperature 40 ℃, culture 20h, obtain pure high-temperature bacterial seed liquid, the number of cells per milliliter is kept at 10 8 A / mL or so;

[0054] (2) Preparation of polymicrothermic bacteria liquid: ① firstly, prepare s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com