High-cushioning-performance composite foam material and preparation method thereof

A compound foaming and high-resistance technology, applied in the field of materials, can solve problems such as user injury, achieve the effects of increasing wear resistance, ensuring mechanical properties and resilience performance, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

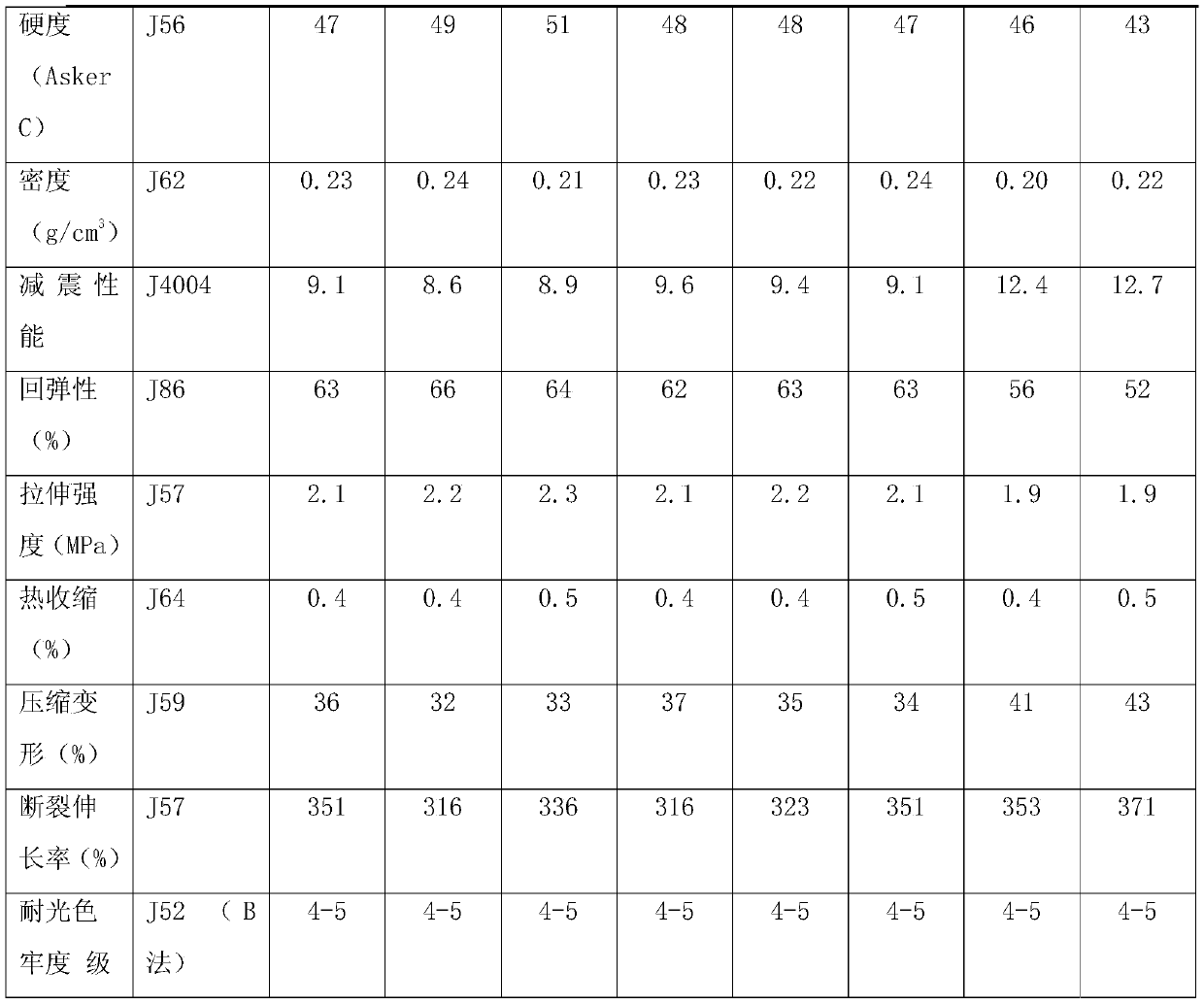

Embodiment 1

[0032] The invention provides a high shock-absorbing composite foaming material, which comprises 25 parts of ethylene-vinyl acetate copolymer, 12 parts of polyolefin thermoplastic elastomer, 10 parts of modified polypropylene, and 15 parts of polyester elastomer in parts by mass. part, 20 parts of natural latex, 0.5 part of surfactant, 0.6 part of borate coupling agent, 0.2 part of crosslinking auxiliary agent, 1 part of crosslinking agent and 2.5 parts of foaming agent.

[0033] Among them, the model of ethylene-vinyl acetate copolymer is 470M produced by Formosa Plastics; the polyolefin thermoplastic elastomer is a mixture of Engage8180 and Engage8450 produced by DuPont, wherein the mass ratio of Engage8180 and Engage8450 is 2:1; modified polypropylene It is Exxon Mobil 7684KN; the type of polyester elastomer is DSM EL430; the active agent is a mixture of stearic acid and fatty acid; natural latex is commercially available; borate coupling agent is produced by Qingdao Siwei C...

Embodiment 2

[0043] A high cushioning composite foaming material, in parts by mass, including 20 parts of ethylene-vinyl acetate copolymer, 12 parts of polyolefin thermoplastic elastomer, 15 parts of modified polypropylene, 12 parts of polyester elastomer, natural 25 parts of latex, 0.5 parts of surfactant, 0.8 parts of borate coupling agent, 0.3 parts of cross-linking auxiliary agent, 1.2 parts of cross-linking agent and 3 parts of foaming agent.

[0044] Among them, the model of ethylene-vinyl acetate copolymer is 7470M produced by Formosa Plastics; the model of polyolefin thermoplastic elastomer is a mixture of Engage8180 and Engage8450 produced by DuPont, wherein the mass ratio of Engage8180 and Engage8450 is 1:1; modified polypropylene It is Exxon Mobil AP7885; the type of polyester elastomer is a mixture of DSM EL430 and EL250, and the mass ratio of EL430 and EL250 is 1:1; the active agent is a mixture of stearic acid and fatty acid; the natural latex It is commercially available; th...

Embodiment 3

[0047] A high cushioning composite foaming material, in parts by mass, including 40 parts of ethylene-vinyl acetate copolymer, 15 parts of polyolefin thermoplastic elastomer, 5 parts of modified polypropylene, 12 parts of polyester elastomer, natural 30 parts of latex, 0.5 parts of surfactant, 0.8 parts of borate coupling agent, 0.3 parts of cross-linking auxiliary agent, 1.2 parts of cross-linking agent and 3.5 parts of foaming agent.

[0048] Among them, the model of ethylene-vinyl acetate copolymer is 7470M produced by Formosa Plastics; the model of polyolefin thermoplastic elastomer is a mixture of Engage8180 and Engage8450 produced by DuPont, wherein the mass ratio of Engage8180 and Engage8450 is 1:1; modified polypropylene It is Exxon Mobil AP7885; the type of polyester elastomer is a mixture of DSM EL430 and EL250, and the mass ratio of EL430 and EL250 is 1:1; the active agent is a mixture of stearic acid and fatty acid; the natural latex It is commercially available; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com