A kind of imidazole pyrophosphate flame retardant and preparation method thereof

A technology of flame retardant and flame retardant nylon, which is applied in the field of phosphorus nitrogen flame retardants, can solve problems such as flammability, achieve the effects of improving flame retardant efficiency, simple and practical preparation method, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

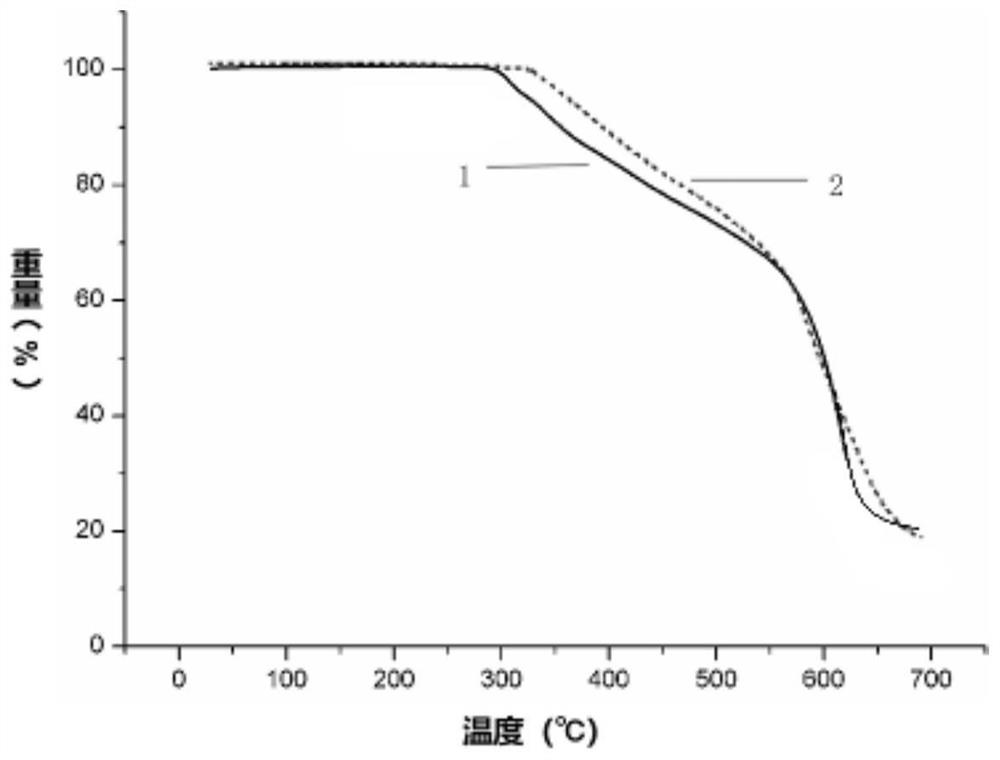

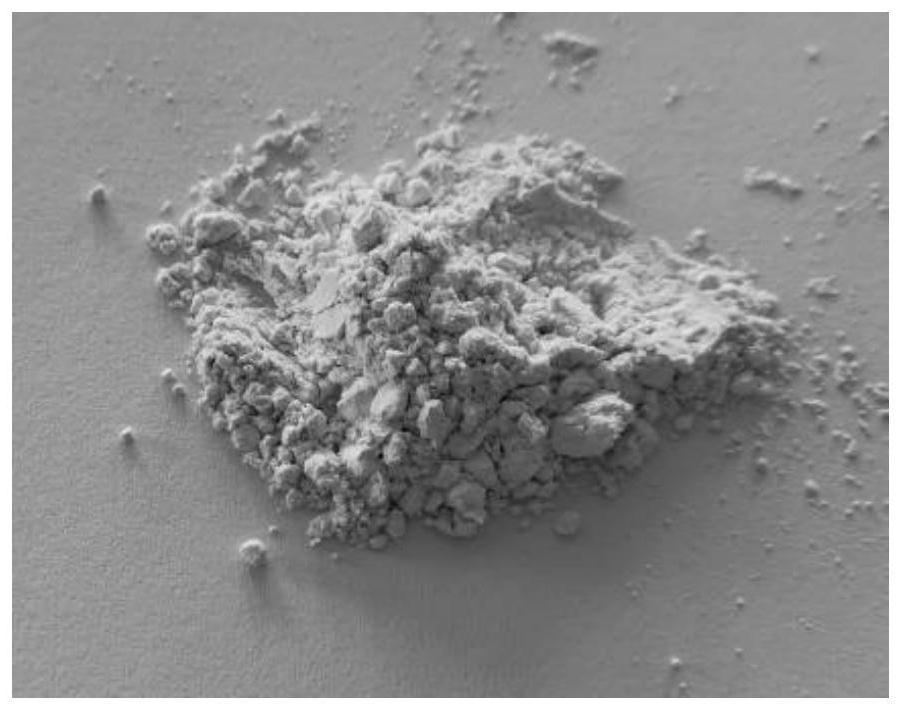

[0040] Add 10 kilograms of 85% phosphoric acid solution to the reaction kettle, the rotating speed is raised to 60rmp, and the temperature is raised to 100°C. The imidazole saturated aqueous solution was added by spraying, wherein the imidazole content was 12.25 kg. After 1 hour of reaction, the mixture was distilled under reduced pressure to remove water to obtain 20.5 kg of white solid of imidazolium phosphate. The imidazolium phosphate salt was added to the vacuum kneader, the rotation speed was increased to 50 rpm, replaced with nitrogen for more than three times, the temperature was raised to 280° C., and the reaction was carried out for 3 hours to obtain the imidazole pyropolyphosphate.

Embodiment 2

[0042] Add 10 kilograms of 85% phosphoric acid solution to the reaction kettle, the rotating speed is raised to 60rmp, and the temperature is raised to 100°C. The imidazole saturated aqueous solution was added in a spraying manner, wherein the imidazole content was 12.25 kg, and the pH of the solution was regulated to 5-6 to stop adding the imidazole saturated aqueous solution. After reacting for 1 hour, the mixture was distilled under reduced pressure to remove water to obtain 22.7 kg of a white solid of imidazolium phosphate. The imidazolium phosphate salt was added to the vacuum kneader, the rotation speed was increased to 50 rpm, replaced with nitrogen for more than three times, the temperature was raised to 280° C., and the reaction was carried out for 3 hours to obtain the imidazole pyropolyphosphate.

Embodiment 3

[0044] Add 10 kilograms of 85% phosphoric acid solution to the reaction kettle, the rotating speed is raised to 60rmp, and the temperature is raised to 100°C. The imidazole saturated aqueous solution was added in a spraying manner, wherein the imidazole content was 12.25 kg, and the pH of the solution was regulated to 5-6 to stop adding the imidazole saturated aqueous solution. After reacting for 1 hour, the mixture was distilled under reduced pressure to remove water to obtain 23.1 kg of a white solid of imidazolium phosphate. The imidazolium phosphate salt was added to the vacuum kneader, the rotating speed was increased to 50 rpm, replaced with nitrogen for more than three times, the temperature was raised to 300° C., and the reaction was carried out for 1.5 hours to obtain the imidazole pyropolyphosphate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com