Porous graphene material and preparation method thereof, capacitor electrode, capacitor and electromotive device

A technology of porous graphene and capacitor electrodes, which is applied in the field of graphene, can solve the problems that the performance cannot meet the needs of use, and achieve the effects of excellent cycle stability, high yield, and controllable specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

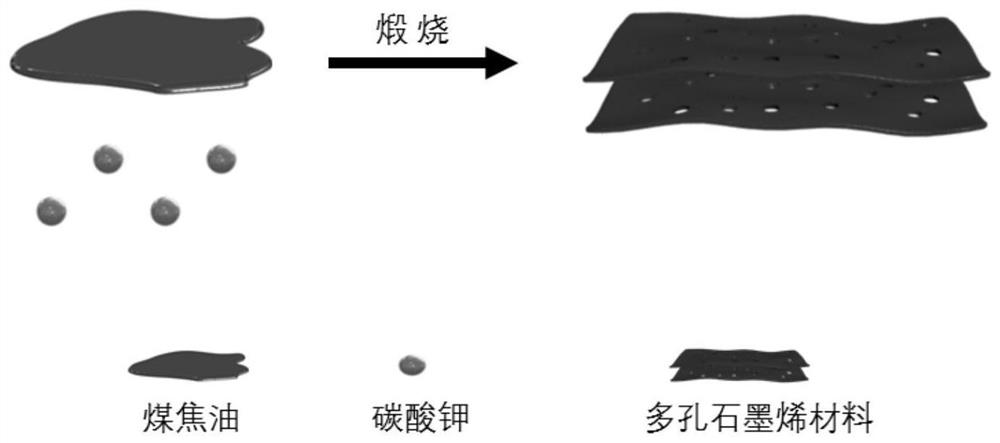

[0056] According to the first aspect of the invention, a method of preparing a porous graphene material comprising the steps of:

[0057] (a) provide a mixture of coal tar and potassium carbonate;

[0058] (b) Calcination of the mixture of coal tar and potassium carbonate is calcined in a protective atmosphere to obtain a porous graphene material.

[0059] Coal tar is mainly a black or dark brown viscous liquid having irritating odor when the coal is dried, referred to as tar. Coal tar prices is low and rich in production, which uses it as a carbon source, which can greatly save production costs.

[0060] Potassium carbonate acts as a mild and environmentally friendly activator to activate the aperture during the calcination (carbonization) process of the coal tar, and exerts a hard template-oriented molding effect.

[0061] The preparation method is used as an activator and a template for potassium carbonate to prepare a porous graphene material by calcining the coal tar as a car...

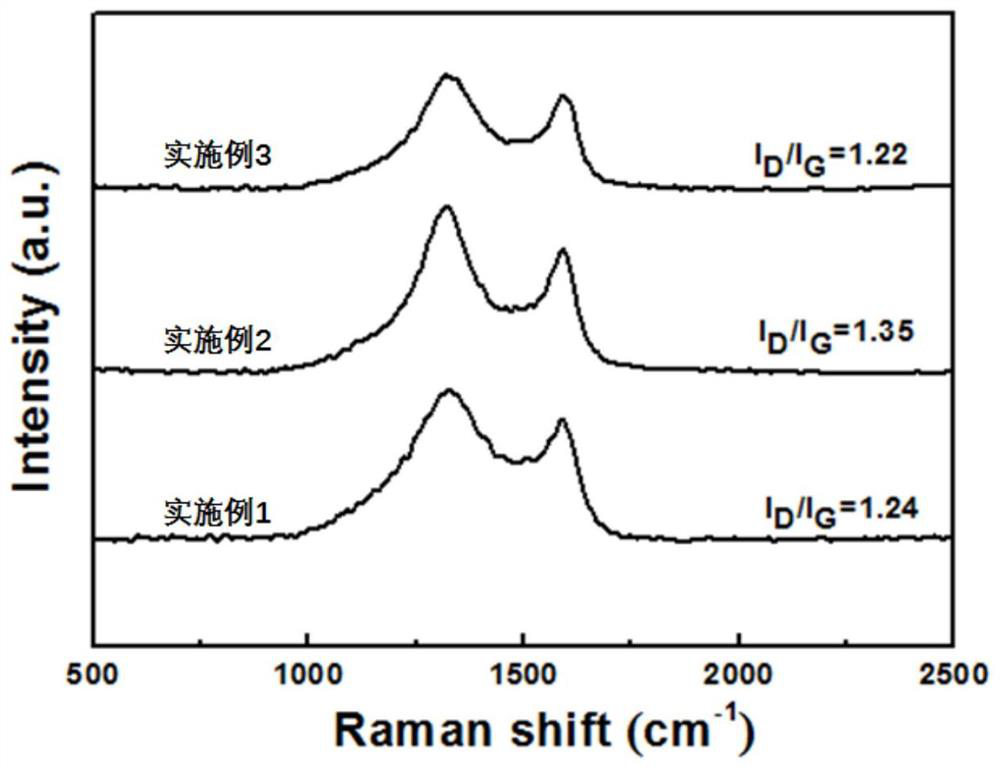

Embodiment 1

[0092] This embodiment provides a method of preparing a porous graphene material comprising the steps of:

[0093] (a) provide a mixture of coal tar and potassium carbonate;

[0094] 1 g of coal tar was ground to the powder to be used in a mortar, and then 3 g of potassium carbonate was sufficiently polished in a mortar, ensuring that coal tar and potassium carbonate was mixed well to obtain a mixture of coal tar and potassium carbonate;

[0095](b) Transfer the mixture of coal tar and potassium carbonate to the rigid jade boat, at a level of 5 ° C / min at a level of 5 ° C / min to 800 ° C constant temperature 2h, then naturally fell to room temperature;

[0096] After the product obtained after the calcined product was cleaned, then washed to neutral with water, and then dried in a hem drying oven at 60 ° C for 8 h to give a porous graphene material.

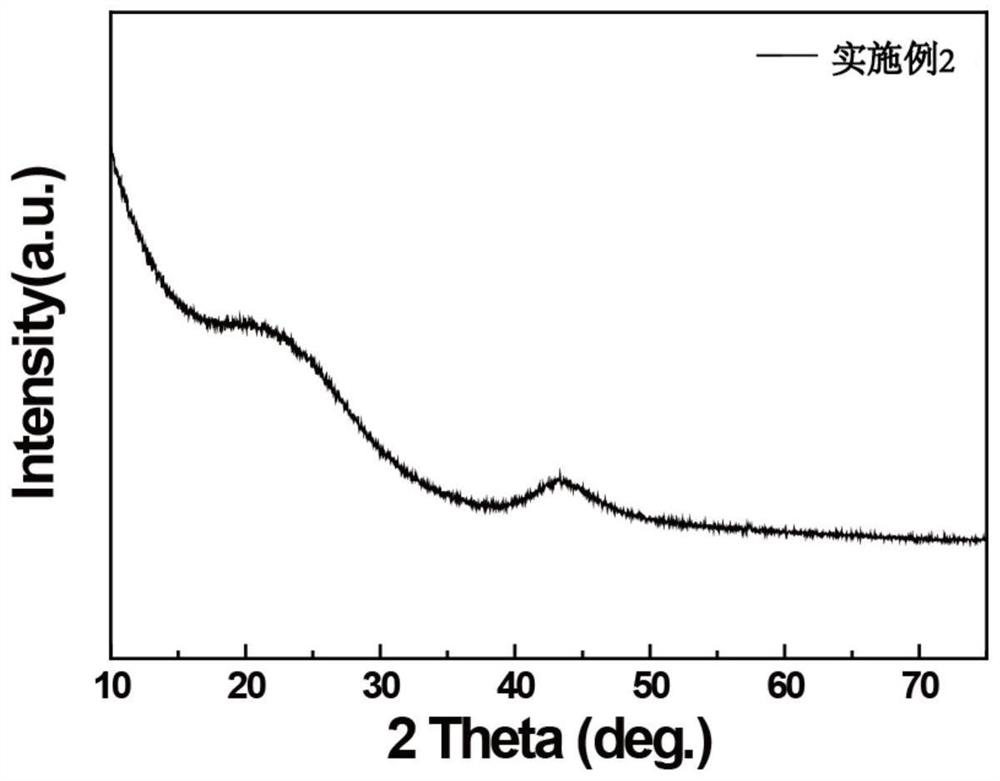

Embodiment 2

[0098] This embodiment provides a method of preparing a porous graphene material, and the amount of potassium carbonate in step (a) is 4 g, the remaining raw materials, amounts, and the preparation method are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com