Product packaging material pressing device facilitating material taking

A product packaging and pressing device technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of increased labor intensity and low work efficiency, and achieve the effect of improving work efficiency and reducing handling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

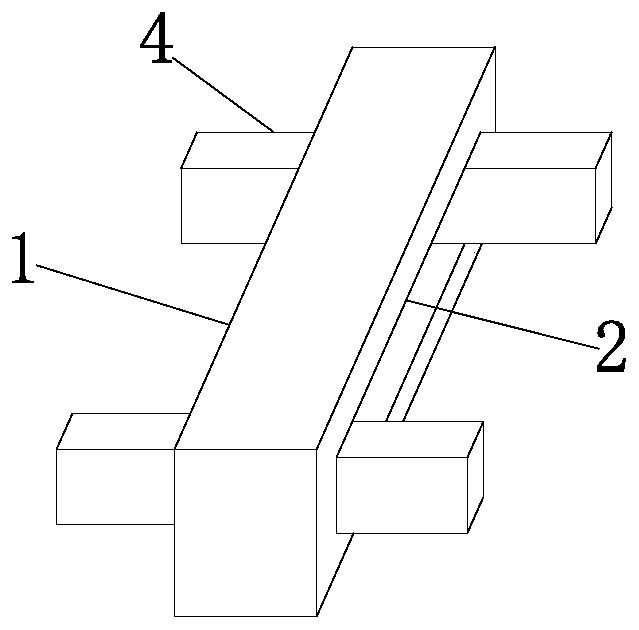

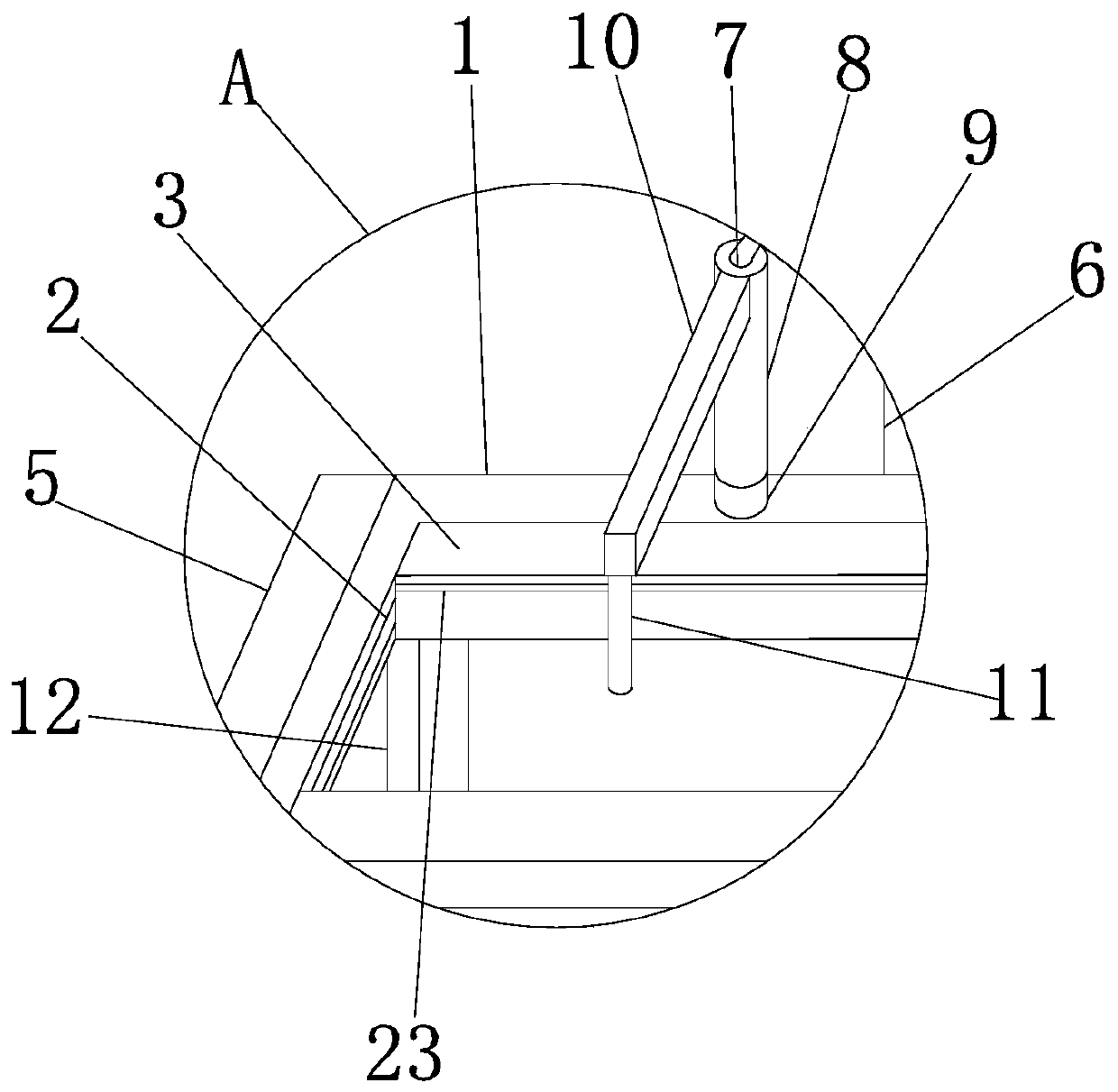

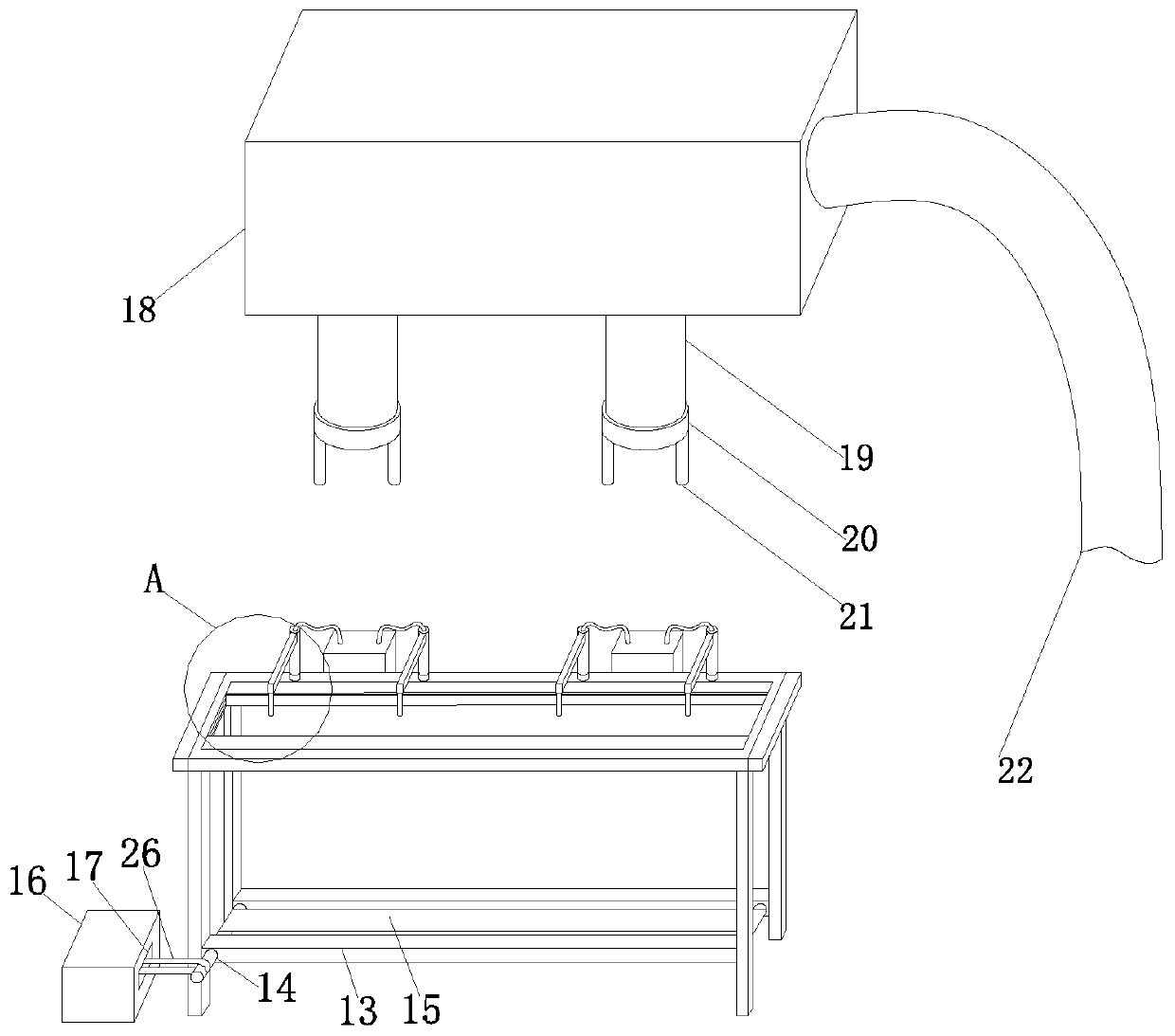

[0021] Embodiment: a kind of product packing that is convenient to take material is used pressing device, as Figure 1-Figure 5As shown, it includes a workbench 1, the workbench 1 is a rectangular workbench, and the inside of the workbench 1 is hollow, and the inner left and right sides of the workbench 1 are provided with chute 2, and the chute 2 is Rectangular chute, a shearing binder 3 is movably connected between the corresponding sides of the two groups of said chute 2, the shearing binder 3 is a rectangular shearing binder, and the shearing binder 3 There are two groups in total, the left side walls of the shearing binder blocks 3 of the two groups are fixedly equipped with a moving block 4, the moving block 4 is a rectangular moving block, and the moving blocks 4 of the two groups pass through the chute 2 and Extending to the left wall surface of the chute 2, the parts of the two groups of moving blocks 4 located on the left side of the chute 2 are movably connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com