Inspection robot slip identification and intelligent self-adaptive control method

A line inspection robot and adaptive control technology, applied in the field of line inspection robots, can solve the problems of insufficient preparation for the adjustment of the pressing force of the pressing motor, insufficient smoothness of the slip control process, and affecting the efficiency of line inspection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

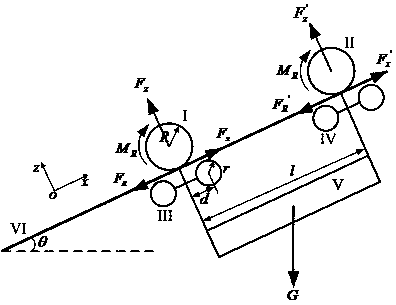

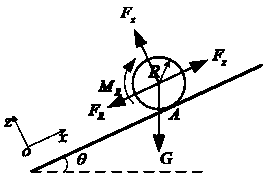

[0046] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

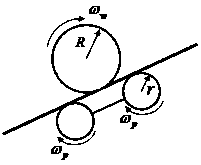

[0047] The invention provides a method of slip identification and intelligent self-adaptive control for a line inspection robot. The line inspection robot includes a walking wheel and a pressing wheel. The walking wheel rolls on the inspected wire, and the pressing wheel is located below the inspected wire. Then the wire to be inspected is tightly pressed on the traveling wheel; the method includes the following steps:

[0048] (1) During the inspection process, the line inspection robot detects whether the travel wheel is slipping in real time by comparing the angular velocity of the travel wheel and the pinch wheel. When detecting whether it is slipping, the pinch wheel is in contact with the inspected wire;

[0049] (2) If no slippage is found in the inspection, continue the inspection. If slippage is found in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com