A foam press-filled honeycomb composite panel and its preparation method

A honeycomb composite panel and foam technology, applied in the field of structural composite materials, can solve the problems of high weight of micro-perforated sound-absorbing panels, difficulty in reducing weight, and short effective service life, and achieve light weight, high foam brittleness, and low production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Polyurethane sound-absorbing foam 4 is made by foaming polyol composite material and isocyanate, the weight ratio of polyol composite material and isocyanate is 1:2.1, wherein:

[0042] Each component of polyol composite material is, in parts by weight:

[0043]

[0044]First, add the components of the weighed polyol composition, except for the inorganic filler, into the reaction kettle and stir for 2 hours to obtain a uniform system A. The temperature of the material is controlled at 28°C; the temperature of the isocyanate is controlled at 28°C. Mix system A with inorganic filler firstly, then inject isocyanate and mix evenly for foaming reaction.

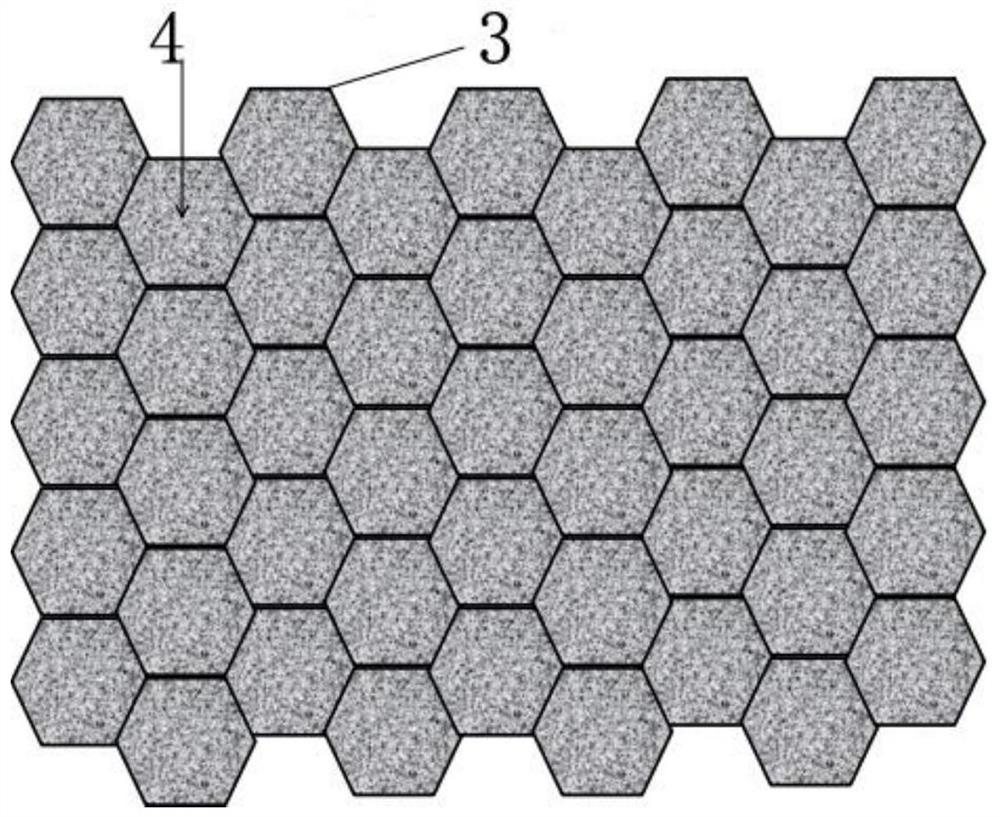

[0045] The prepared polyurethane sound-absorbing foam 4 is cut out of a bare board with a specification of 1m*1m*15mm and a cylindrical structural paper honeycomb core of the same specification is stacked between the flat plates of the flat press machine, and the foam board is stacked under the honeycomb core. The metho...

Embodiment 2

[0047] Polyurethane sound-absorbing foam 4 is made of polyol composite material and isocyanate through foaming process, the weight ratio of polyol composite material and isocyanate is 1:1.4, wherein:

[0048] Each component of polyol composite material is, in parts by weight:

[0049]

[0050]

[0051] First, add the components of the weighed polyol composition, except for the inorganic filler, into the reaction kettle and stir for 3 hours to obtain a uniform system A. Control the temperature of the material at 20°C; control the temperature of the isocyanate at 20°C, Mix system A with inorganic filler firstly, then inject isocyanate and mix evenly for foaming reaction.

[0052] The prepared polyurethane sound-absorbing foam 4 is cut out of a bare board with a specification of 1m*1m*20mm and the hexagonal structure paper honeycomb core of the same specification is stacked between the flat plates of the flat press machine, and the foam board is stacked under the honeycomb ...

Embodiment 3

[0054] Polyurethane sound-absorbing foam 4 is made of polyol composite material and isocyanate through foaming process, the weight ratio of polyol composite material and isocyanate is 1:1.65, wherein:

[0055] Each component of polyol composite material is, in parts by weight:

[0056]

[0057] First, add the components of the weighed polyol composition, except the inorganic filler, into the reaction kettle and stir for 2 hours to obtain a uniform system A. Control the temperature of the material at 23°C; control the temperature of the isocyanate at 22°C, Mix system A with inorganic filler firstly, then inject isocyanate and mix evenly for foaming reaction.

[0058] The prepared polyurethane sound-absorbing foam 4 is cut out of a bare board with a specification of 1m*2m*30mm and the hexagonal structure paper honeycomb core of the same specification is stacked between the flat plates of the flat press machine, and the foam board is stacked under the honeycomb core. The meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com