Intelligent assembly line for buckle screws

An assembly line and buckle technology, which is applied in non-electric welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of production line functional limitations and inability to meet the production needs of automobile door panels, and meet the needs of efficient processing, good locking effect, and optimized Effect of Die Locking Mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

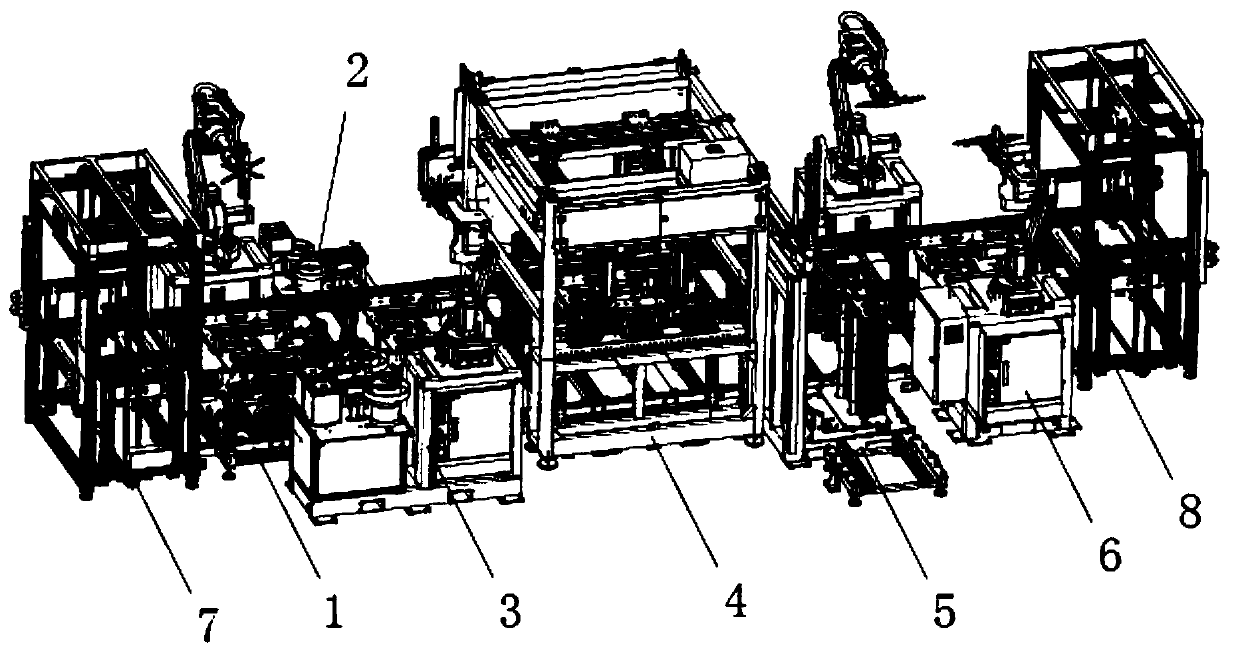

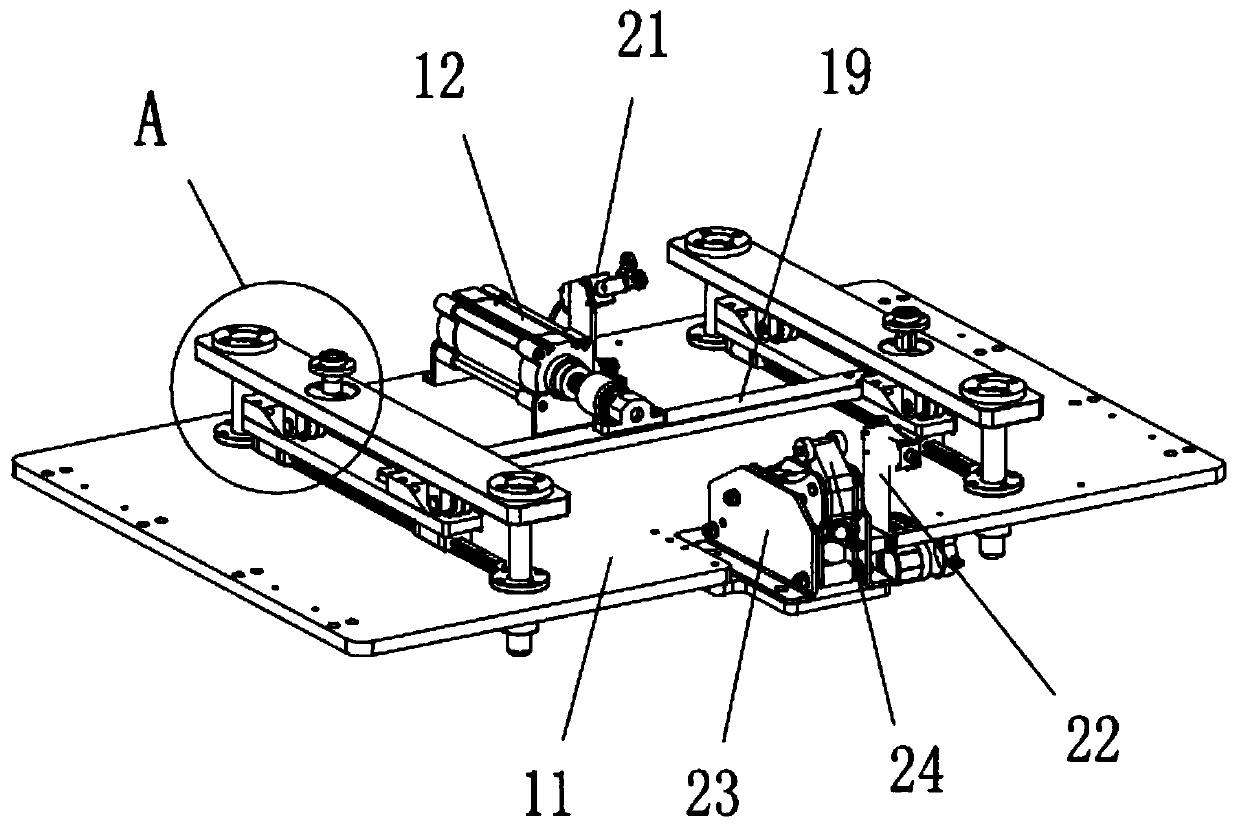

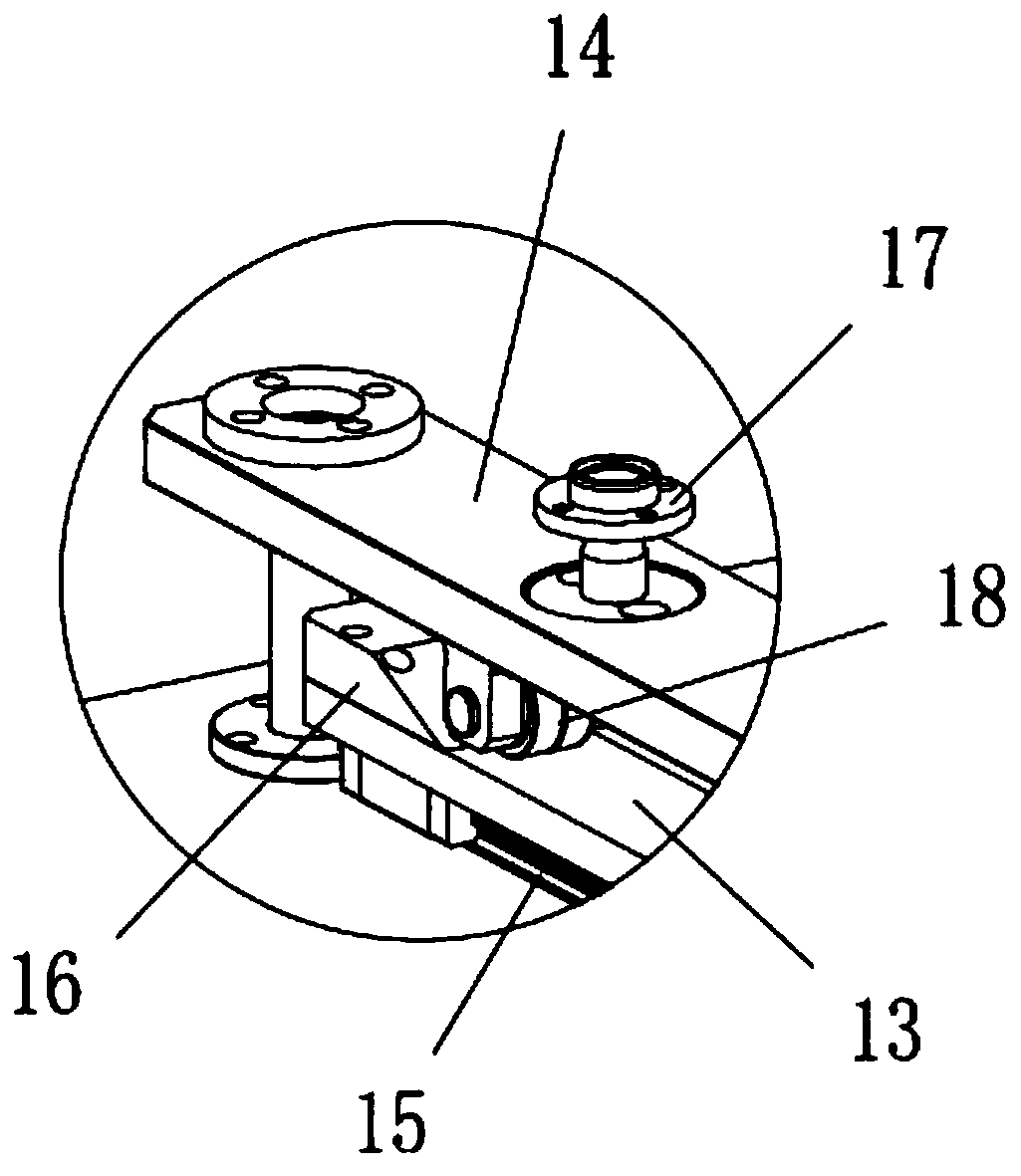

[0026] like figure 1 As shown, a snap screw intelligent assembly line according to the present invention includes a conveying line 1, a snap screw installation station, a snap installation station, a multi-axis welding station, a sound-absorbing cotton feeding station and an ultrasonic welder position; the conveying line 1 is used to transport the mold carrying the workpiece, and the mold passes through the above-mentioned stations in sequence, and the conveying line 1 is provided with a mold locking mechanism corresponding to each station, and the mold locking mechanism is used to lock the mold carrying the workpiece At the current station; the snap screw installation station is provided with a snap screw installation mechanism 2, the snap installation station is provided with a snap installation mechanism 3, and the multi-axis weldi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com