Intelligent rolling mill liquid supply control system

A technology of controller and rolling force, applied in the direction of temperature control, etc., can solve problems such as poor plate shape, damage to the plate surface, and plate surface slippage, so as to improve the quality of the plate surface, increase the rate of first-class products, and reduce the liquid supply The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

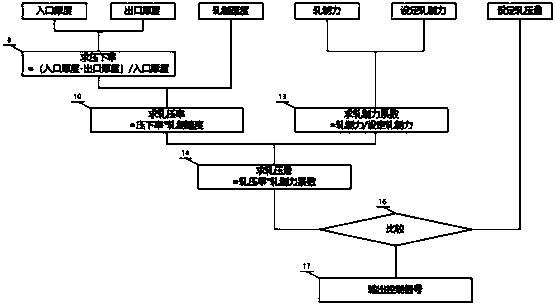

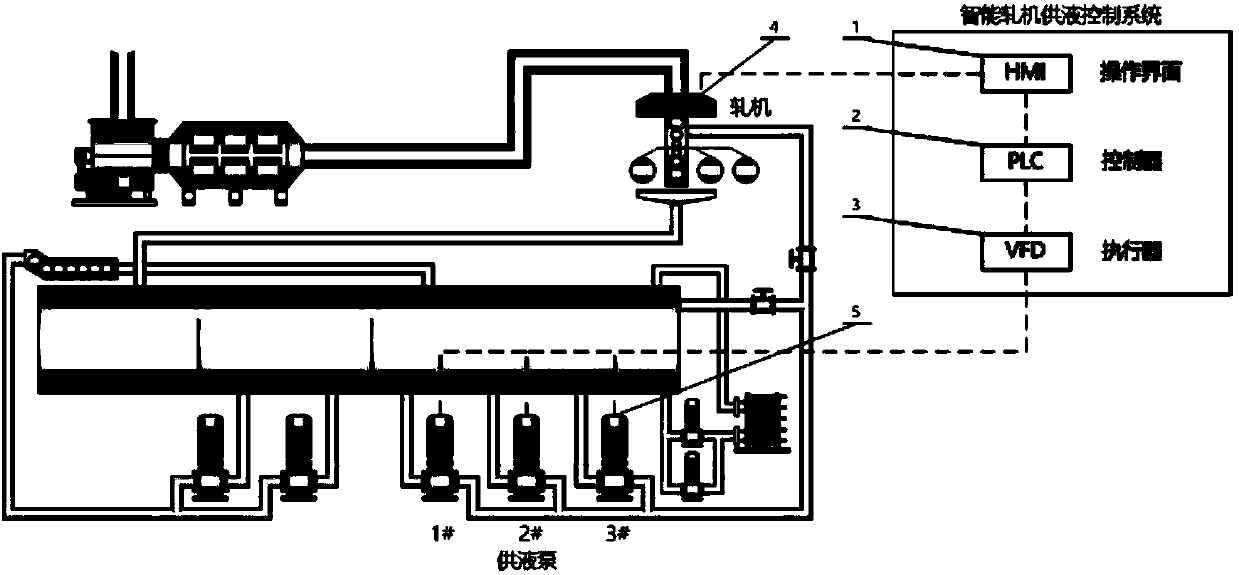

[0011] The entrance thickness (6) and exit thickness (7) of the rolling mill (4) are collected through the operation interface (1), the reduction rate (8) is calculated in the controller (2), and the rolling mill (4) is collected through the operation interface (1). rolling speed (9), calculate the rolling pressure rate (10) in the controller (2), collect the rolling force (11) and set rolling force (12) of the rolling mill (4) through the operation interface (1), and control Calculate the rolling force coefficient (13) in the device (2), calculate the rolling force (14) in the controller (2), set the rolling force (15) through the operation interface (1), and set the rolling force (15) in the controller (2) Comparing (16) with the calculated rolling pressure (14), the output control signal (17) is given to the actuator (3), and the actuator (3) outputs a notification command to the liquid supply pump (5), thereby controlling the liquid supply system of the rolling mill intell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com