Waste gas treatment environment-friendly box

A waste gas treatment and environmental protection box technology, which is applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of inconvenient equipment disassembly and transportation, troublesome disassembly and assembly, etc., achieve easy disassembly and assembly, and improve connection air tightness , to ensure the effect of stable support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

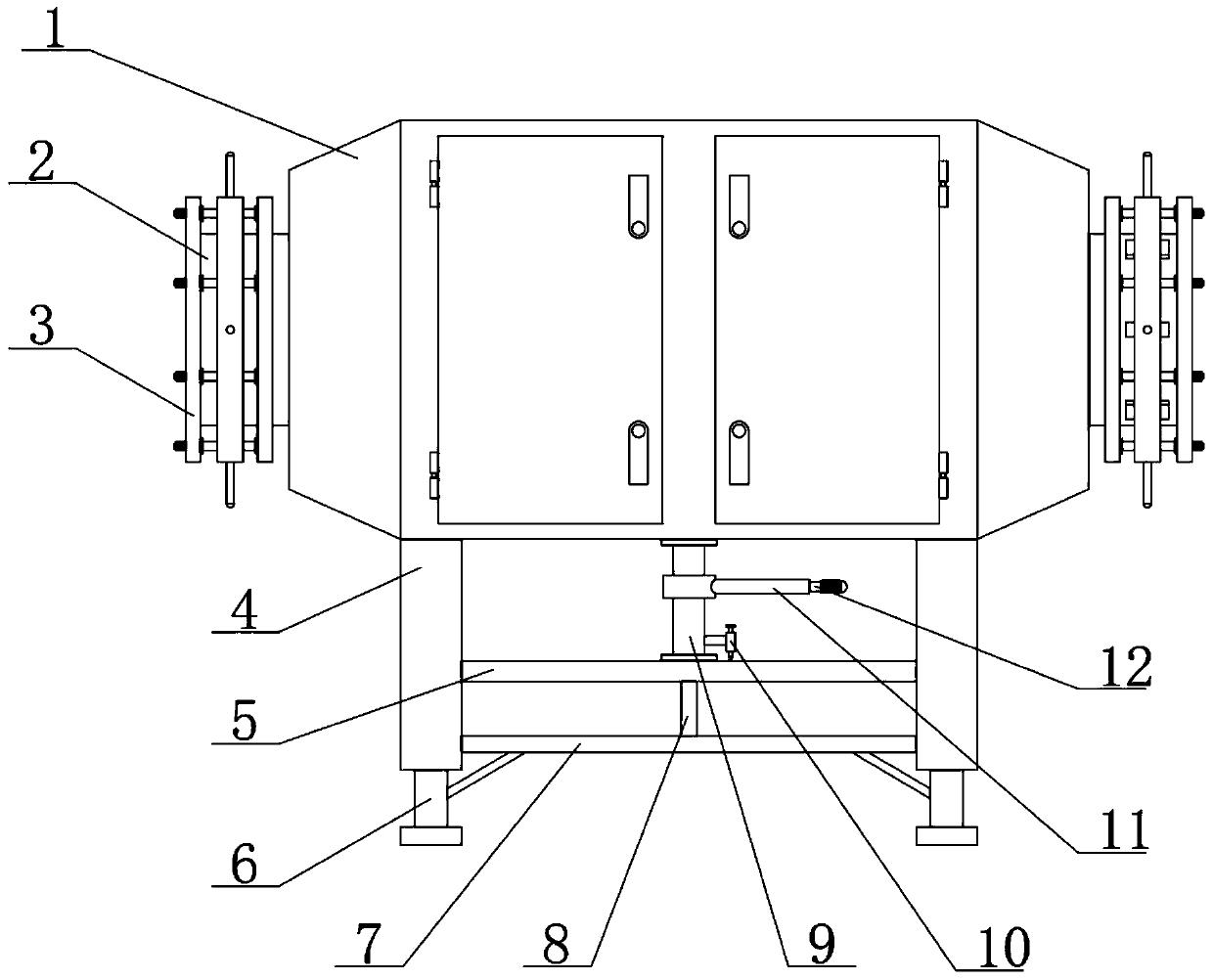

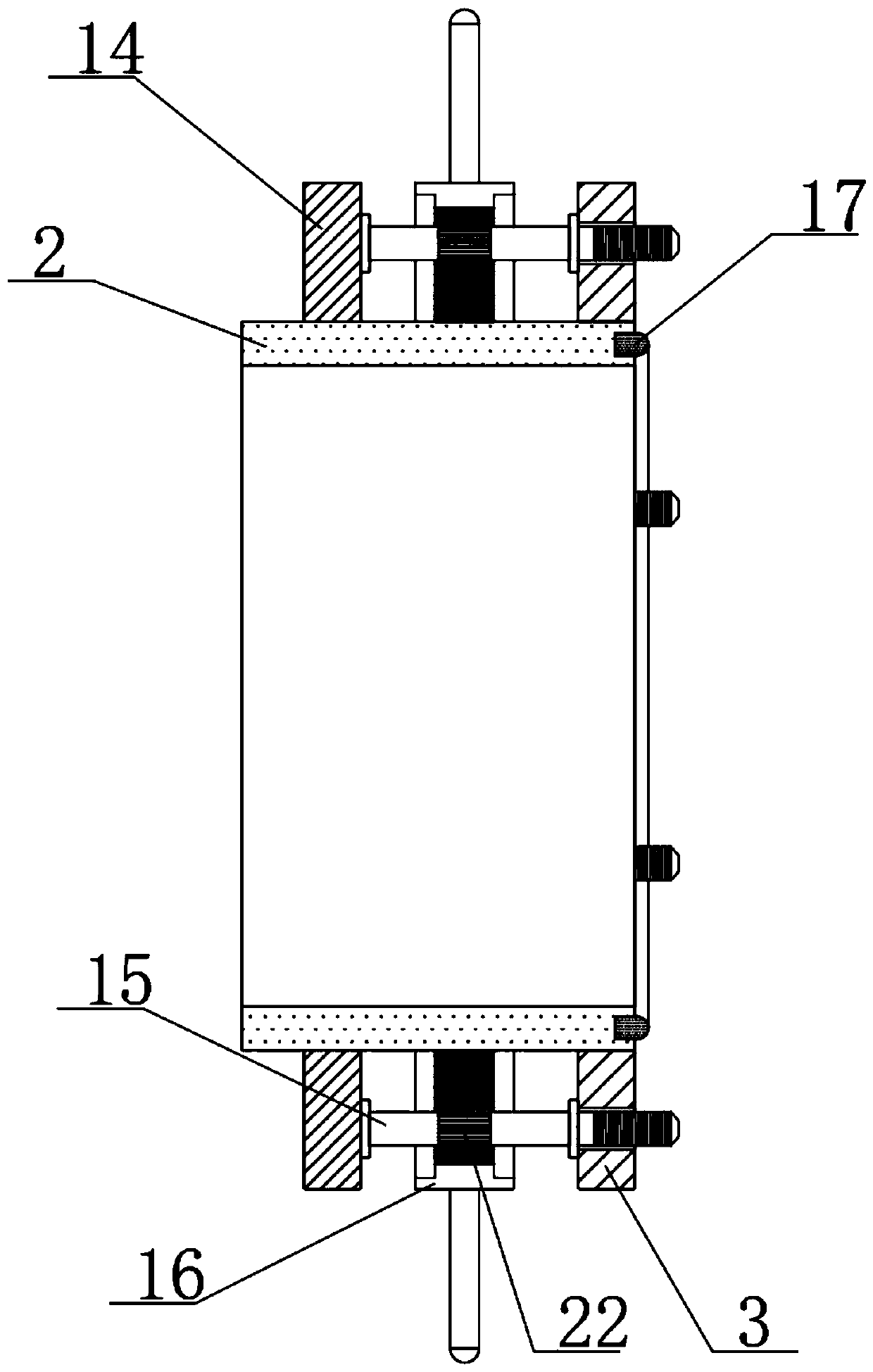

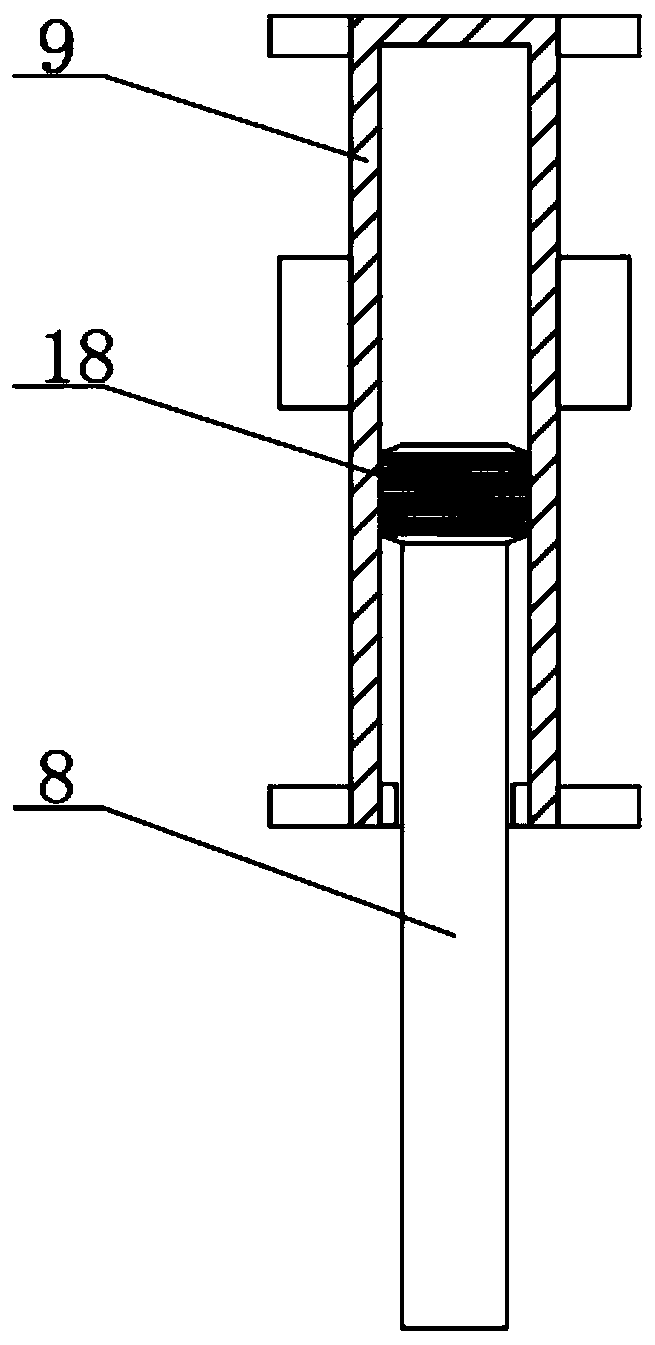

[0023] See Figure 1-Figure 5 , The present invention provides a technical solution: an environmental protection box for waste gas treatment, including an environmental protection box body 1, a connecting pipe 2, a flange 3, and a support tube 4. The support tube 4 is fixedly installed on the four corners of the lower surface of the environmental protection box body 1, and the connecting tube 2 Welding and fixing to the air inlet and exhaust opening of the environmental protection box body 1, the flange 3 is welded and fixed to the end of the connecting pipe 2, and the outer surface of the connecting pipe 2 is fixed with a fixing ring 14, which is connected to the flange A round rod 15 is arranged between the flanges 3 through a bearing rotation, and the end of the round rod 15 is fixedly provided with bolts. The bolts penetrate the outer surface of the flange 3, and the round rods 15 are evenly spaced around the outer surface of the connecting pipe 2. The outer surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com