Fruit cleaning and screening device

A screening device, fruit technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of poor screening results, low work efficiency, low efficiency, etc., to achieve the effect of avoiding damage and convenient packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further explained by specific examples below.

[0019] Include the following steps:

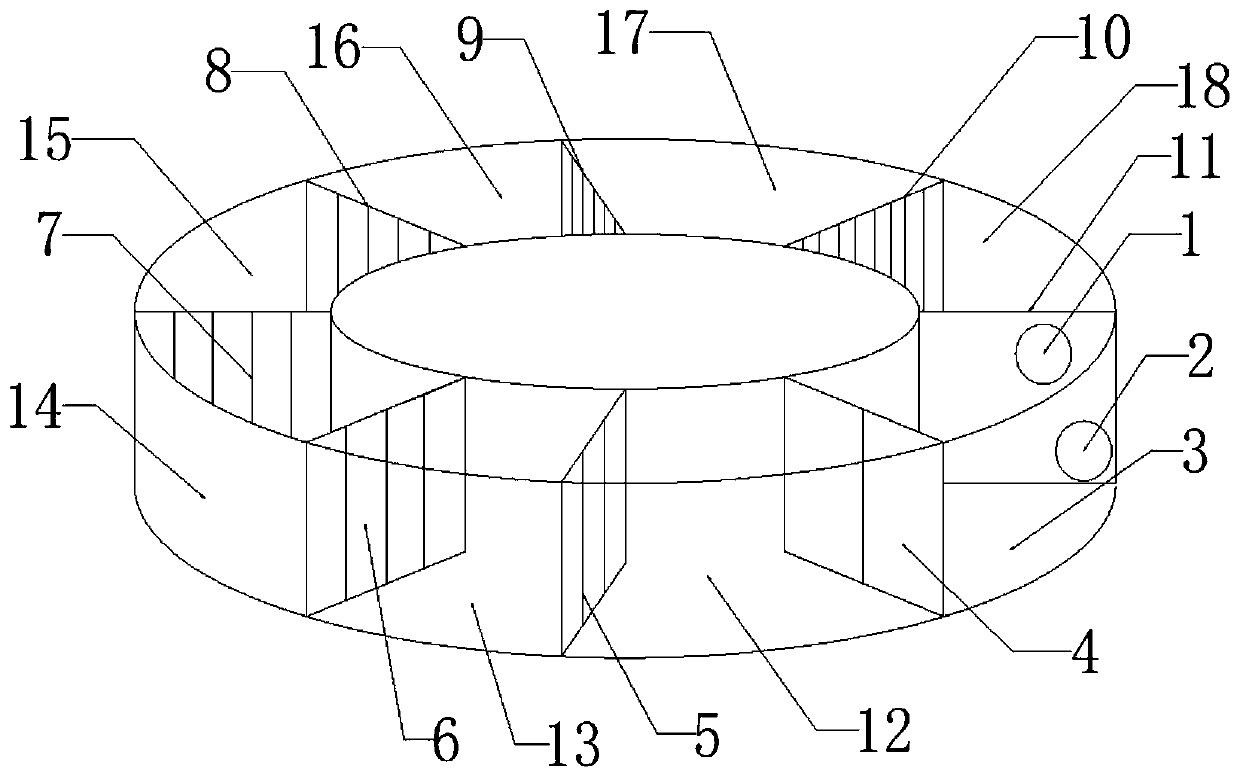

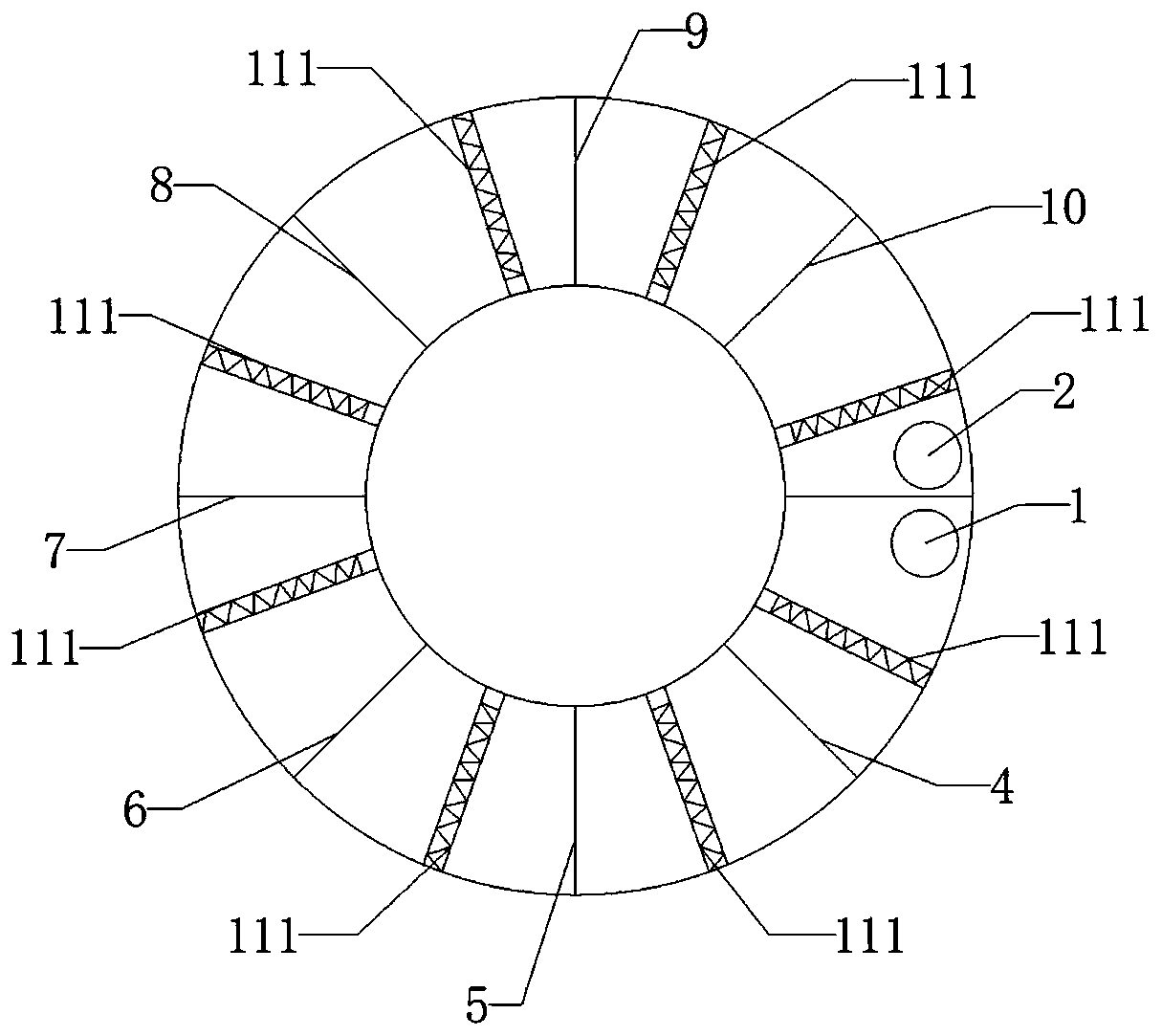

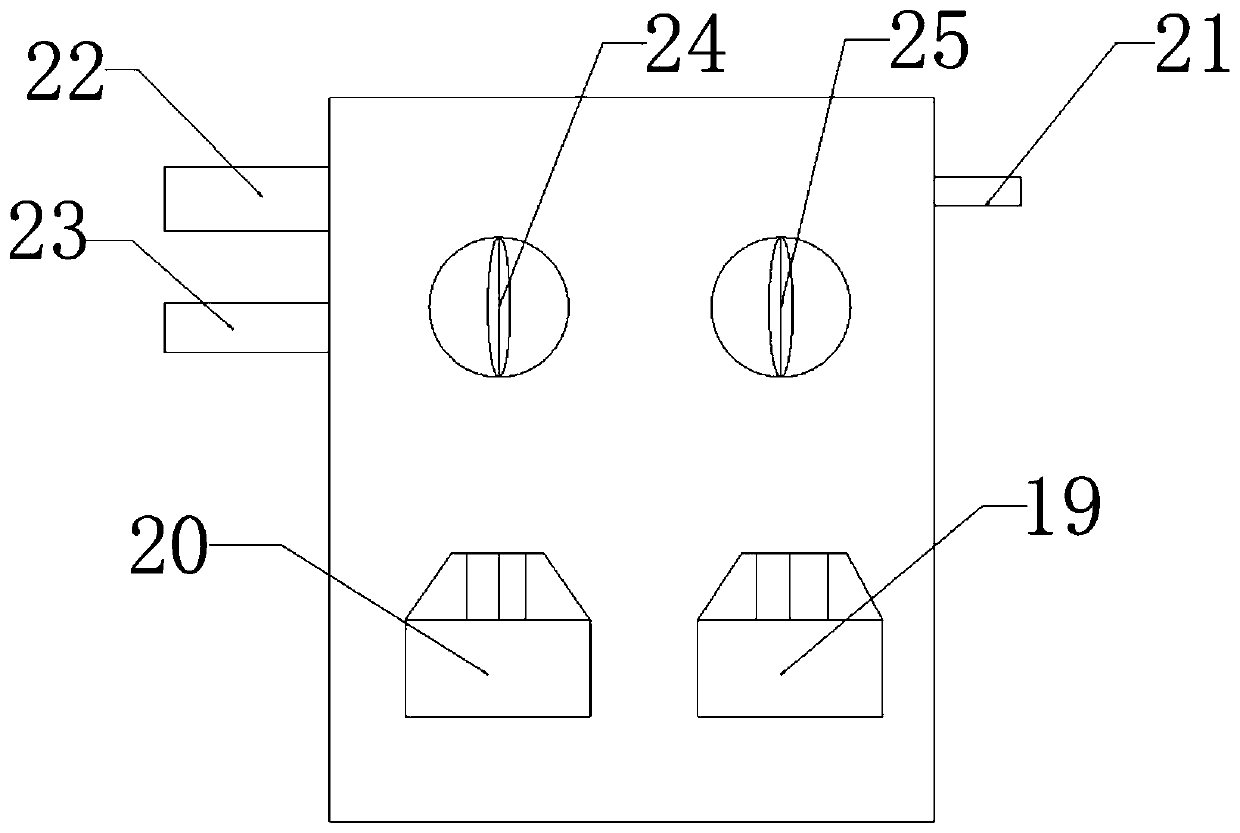

[0020] The first step is to connect the interface 1 21 and interface 3 23 with the water inlet 1 and the water outlet 2 respectively, splice the screening boxes and install the screens in the order of aperture from large to small in the contact of adjacent screening boxes. face, that is, install in a clockwise direction.

[0021] In the second step, after the fruit is put into the fruit holding box, the water pump 19 and the valve 124 are turned on to let the water enter, and a stable clockwise water flow is formed between the screening boxes, and the fruit is automatically sieved, while the roller brush 111 follows the rotation The fruit is cleaned, and the water pump 19 is closed after cleaning and sieving, and the water flows out from the water outlet.

[0022] The third step is to separate interface one 21 and interface three 23 from water inlet 1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com