A printed circuit substrate with high-precision rectangular positioning micro-grooves and its manufacturing method

A technology of circuit substrate and manufacturing method, which is applied in the direction of printed circuit manufacturing, printed circuit, printed circuit, etc., can solve the problems that the positioning micro-groove spacing accuracy cannot be guaranteed, the cumulative error is large, and the yield rate is reduced, so as to reduce stress and reduce Effect of transmission loss and improvement of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

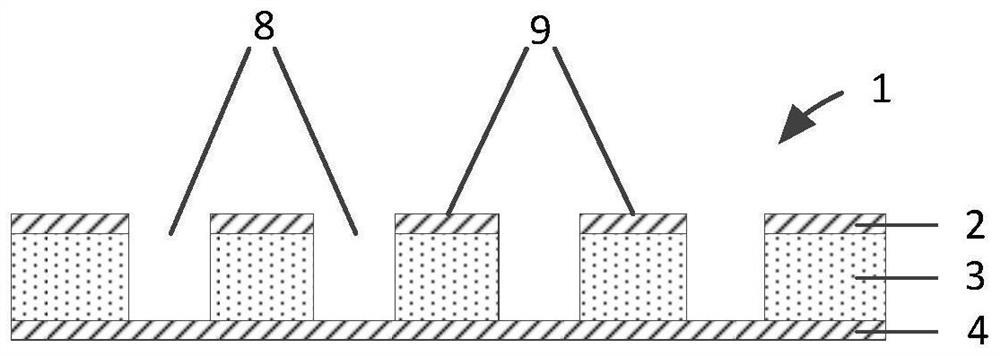

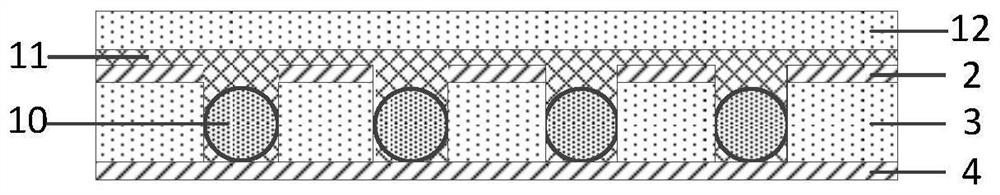

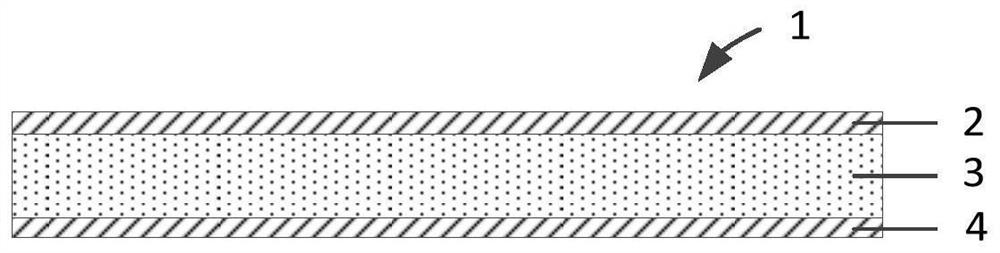

[0028] A printed circuit substrate with high-precision rectangular positioning microgrooves, such as figure 1 As shown, it includes a printed circuit substrate 1; the printed circuit substrate 1 includes a base material layer 3, a first copper foil layer 2 and a second copper foil layer 4 arranged on the opposite surface of the base material layer; The first copper foil layer 2 is provided with several uniformly distributed rectangular openings 7 (such as Figure 7 shown), the rectangular opening penetrates the first copper foil layer 2 and the substrate layer 3 to the upper surface of the second copper foil layer 4 to form a rectangular positioning microgroove 8 (such as Figure 9 shown), the depth and width of the rectangular positioning microgroove 8 are slightly larger than the diameter of the bare optical fiber 10, to ensure that a bare optical fiber can be fully accommodated (such as figure 2 As shown), two adjacent rectangular positioning microgrooves are separated by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com