A dual-cavity coupled noise generator and power generation method

A coupling type and generator technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve the negative effects of electromagnetic field on human body, large volume of sound wave power generation equipment, Problems such as difficulties in practical application, to achieve the effect of large application value, increased voltage, and increased vibration amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

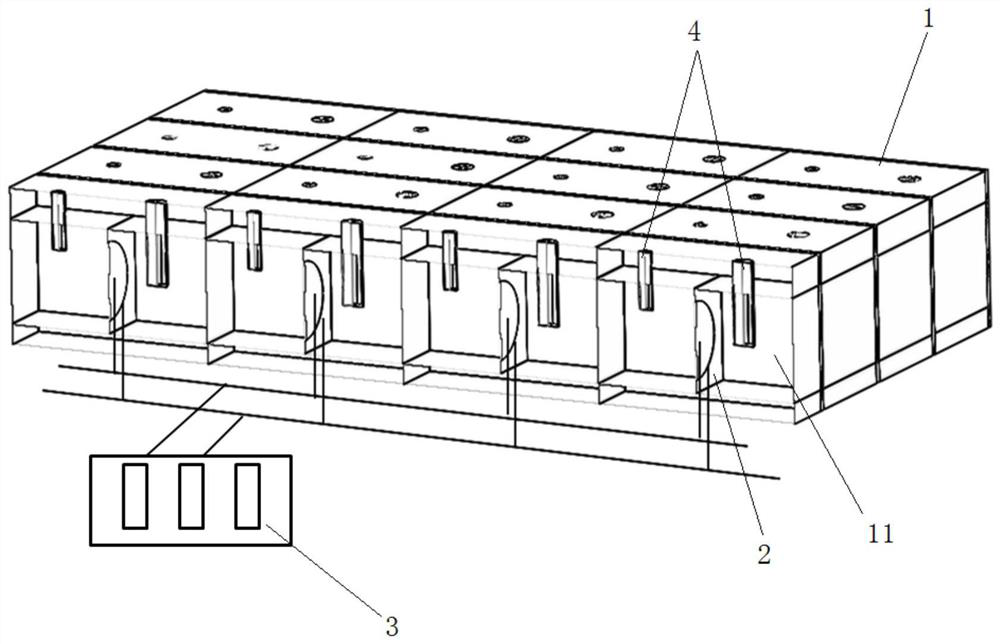

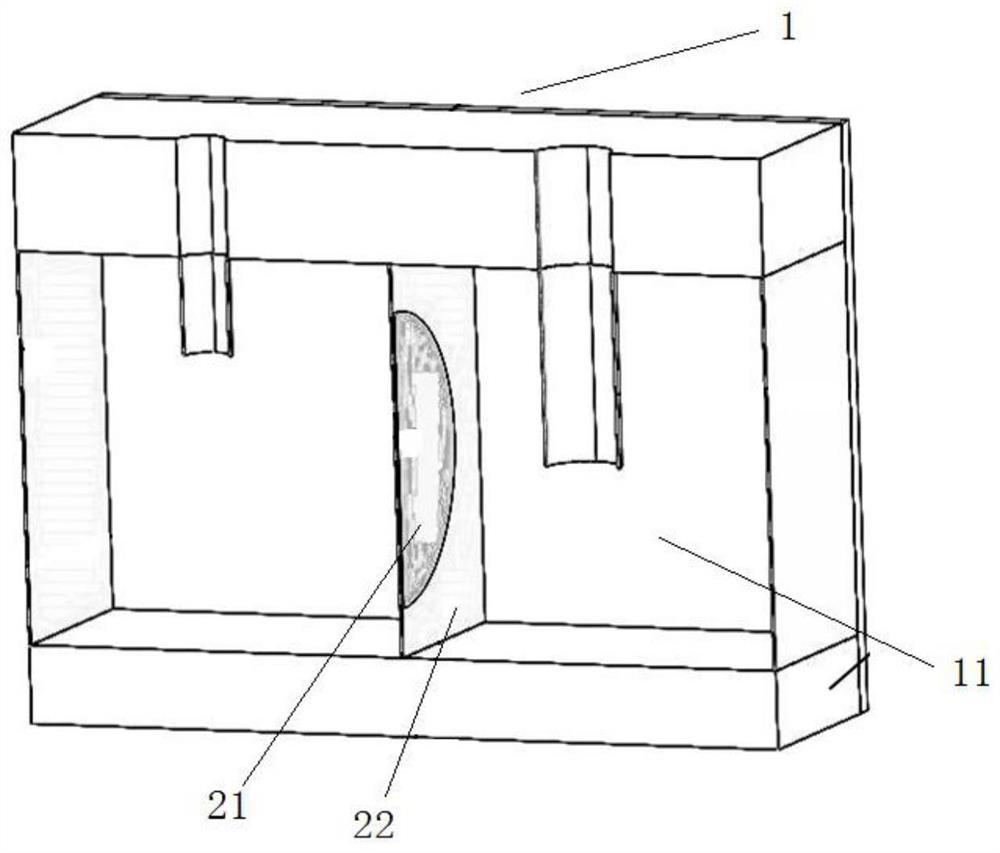

Embodiment 1

[0047] In this embodiment, the Helmholtz resonators 1 are arranged in series in a 4*4 array, and the closed resonant cavity 11 of the Helmholtz resonator 1 has an open top wall with a wall thickness of h 1 =6mm, the top wall of one closed resonant cavity 11 has a radius R 1 The small hole, the top wall of another closed resonant cavity 11 is opened with a radius R 2 large hole. For a bottom wall without openings, the wall thickness h 2 = 4 mm. The side wall between the two chambers, wall thickness h m =0.1mm, made of aluminum. Both the front panel and the rear panel used to form the closed cavity have a thickness of 1 mm. The cavity volumes of the two coupled closed resonant cavities 11 are the same, and both can be of length a 1 = 20mm, width a 2 =22mm, height a 3 = 20mm.

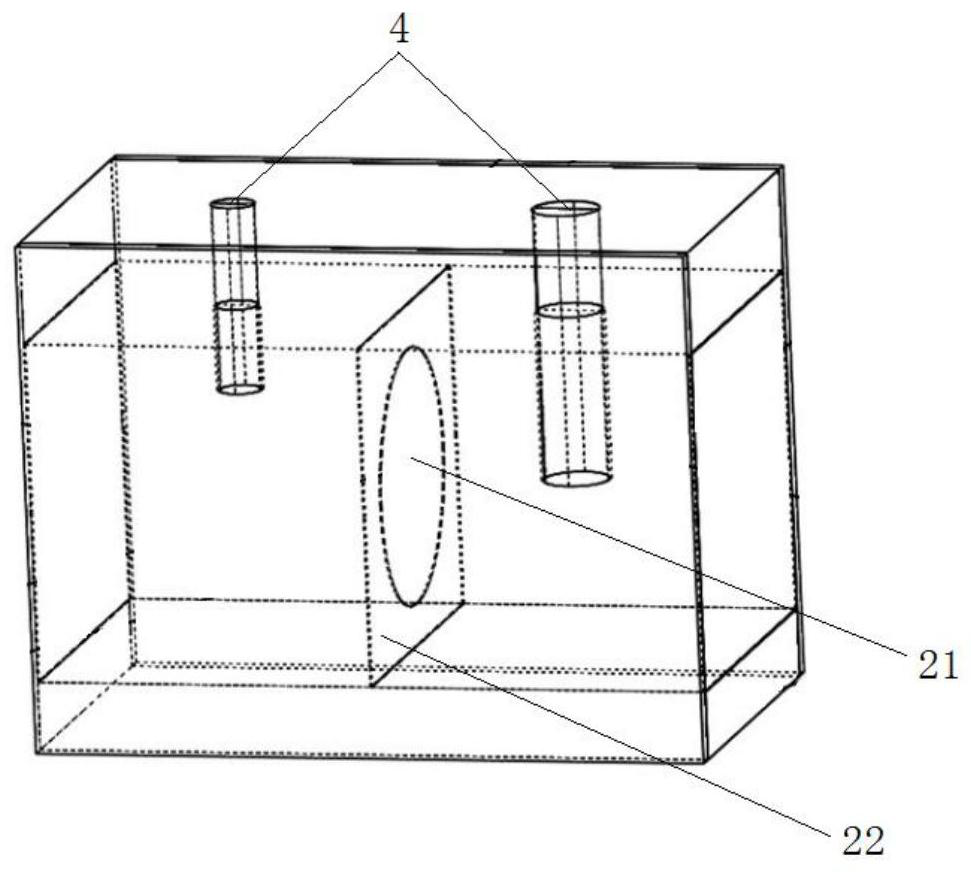

[0048] The electrode sheet 22 of this embodiment is also an aluminum rectangular sheet with a length of 20 mm, a width of 22 mm, a height of 20 mm, and a thickness of 0.1 mm. The piezoelectric ce...

Embodiment 2

[0052] In this embodiment, the top wall of the opening of the Helmholtz cavity 1 has a wall thickness h 1 =6mm, the top wall of one closed resonant cavity 11 has a radius R 1 The small hole, the top wall of another closed resonant cavity 11 is opened with a radius R 2 large hole. For a bottom wall without openings, the wall thickness h 2 = 4 mm. The side wall between the two chambers, wall thickness h m =0.1mm, made of aluminum. Both the front panel and the rear panel used to form the closed cavity have a thickness of 1 mm. The cavity volumes of the two coupled closed resonant cavities 11 are the same, and both can be of length a 1 = 20mm, width a 2 =22mm, height a 3 = 20mm.

[0053] The electrode sheet 22 of this embodiment is also a copper rectangular sheet with a length of 20 mm, a width of 22 mm, a height of 20 mm, and a thickness of 0.1 mm. The piezoelectric ceramic sheet 21 is a circular piezoelectric ceramic sheet 21 with a radius of 9 mm and a thickness of 0....

Embodiment 3

[0058] In the present embodiment, the thickness of extension neck 4 is a thin circular tube of 0.1 mm, and the diameters are R 1 = 1.2mm, R 2 =1.9mm, the lengths of the extension neck 4 in the cavity are L respectively 1 = 0 mm, L 2 = 9 mm.

[0059] Others are all the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com