Cable water blocking method

A cable and water blocking technology, which is used in equipment for connecting/terminating cables, repairing equipment for insulated/armored cables, etc. It can solve the problems of cable failure, low reliability and safety, and achieve improved reliability and increased service life. , the effect of increasing the longitudinal water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

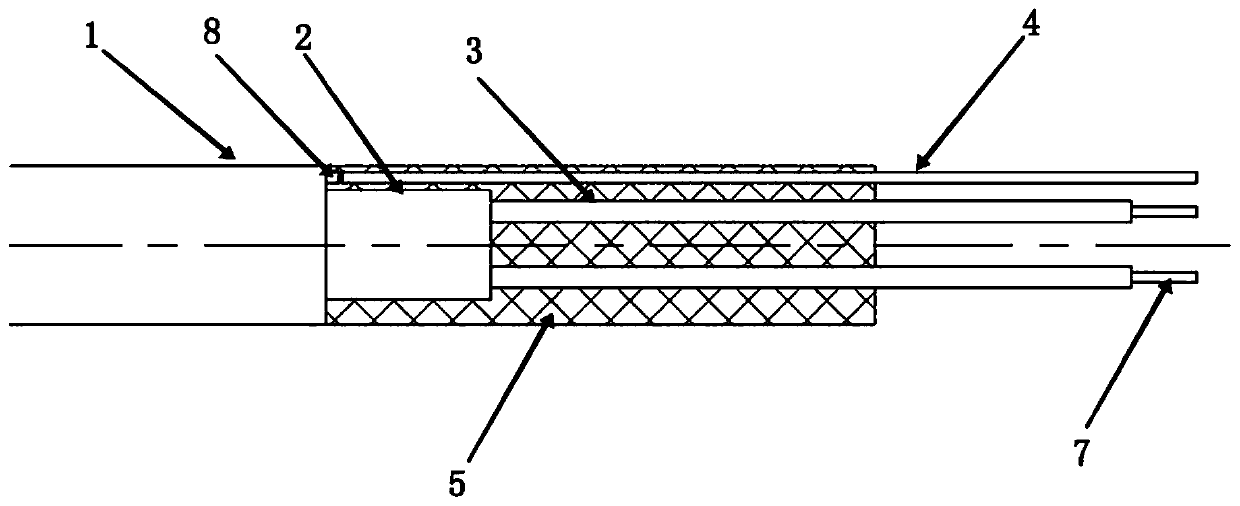

[0019] Embodiment 1: A kind of cable water blocking method, such as figure 1 Applied to the cable end, the method includes the following steps:

[0020] Step 1: Strip off the outer sheath 1, inner sheath 2, core wire insulation layer 3 of a certain length of cable in turn at the end of the cable and expose the core wire 7, so that the outer sheath 1, inner sheath 2 and core wire The stripped length of the insulating layer 3 along the length direction decreases successively;

[0021] Step 2: When water-blocking treatment is performed on the end of the cable, the shielded wire 8 is cut off at the end face near the outer sheath 1, and the broken point is connected to the bare copper wire 4 with solder.

[0022] Step 3: Using rubber 5 or polyurethane 6 to rebond the outer sheath 1, the inner sheath 2 and the core wire insulation layer 3 together.

Embodiment 2

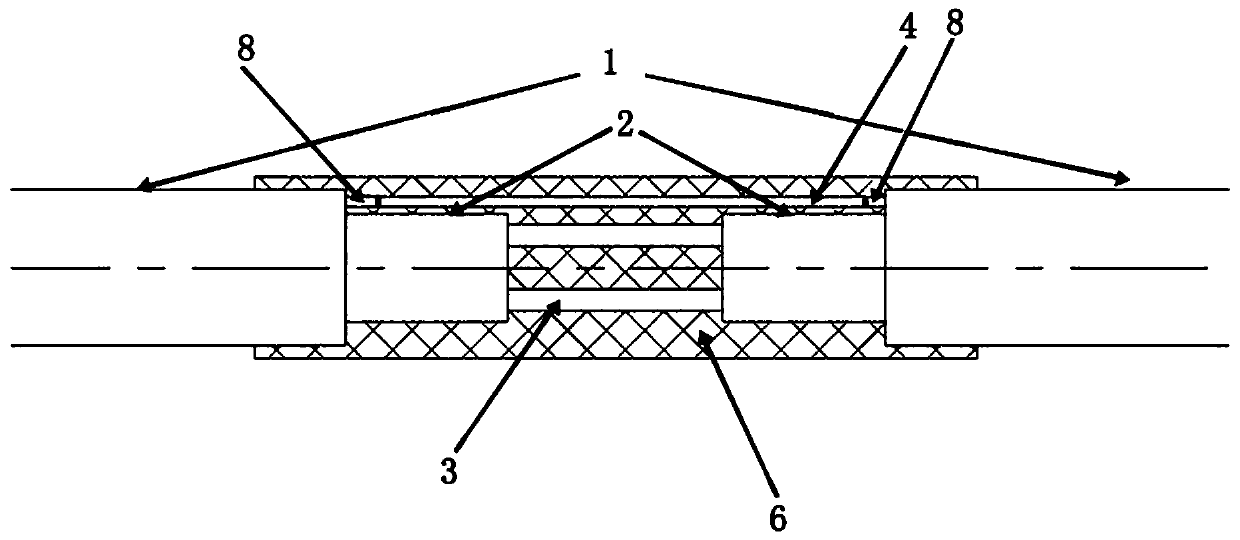

[0023] Embodiment 2: A kind of cable water blocking method, such as figure 2 Applied to the middle of the cable, the method includes the following steps:

[0024] Step 1: In the middle of the cable, peel off the outer sheath 1 and inner sheath 2 of a certain length of cable and expose the core wire insulation layer 3, so that the outer sheath 1, inner sheath 2 and core wire insulation layer 3 are along the length The stripped length in each direction decreases successively.

[0025] Step 2: When performing water-blocking treatment on the middle part of the cable, cut off the shielded wire 8 at the end faces on both sides of the outer sheath 1 respectively, and connect the two breakpoints with the bare copper wire 4 with solder.

[0026] Step 3: Use rubber 5 or polyurethane 6 to rebond the outer sheath 1, inner sheath 2 and core wire insulation layer 3 together, that is, use rubber vulcanization or polyurethane perfusion.

[0027] As another preferred technical solution: on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com