A dynamically adjustable multi-core optical fiber composite self-suspending cable

A multi-core optical fiber and dynamic adjustment technology, which is applied in the field of underwater cables, can solve the problems of inconvenient depth adjustment of underwater construction equipment, and achieve the effects of good insulation, high strength, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

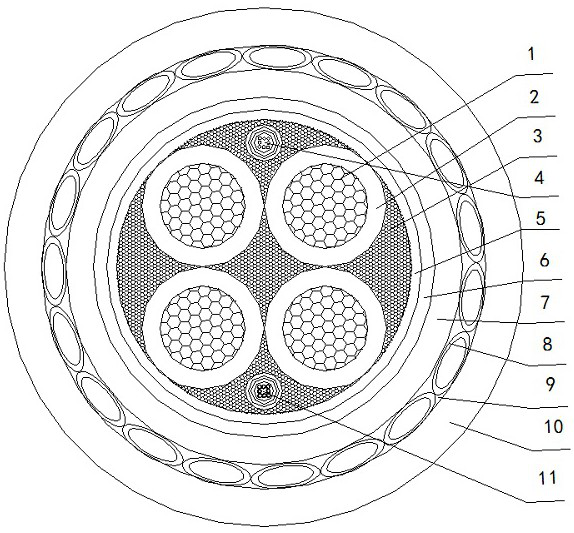

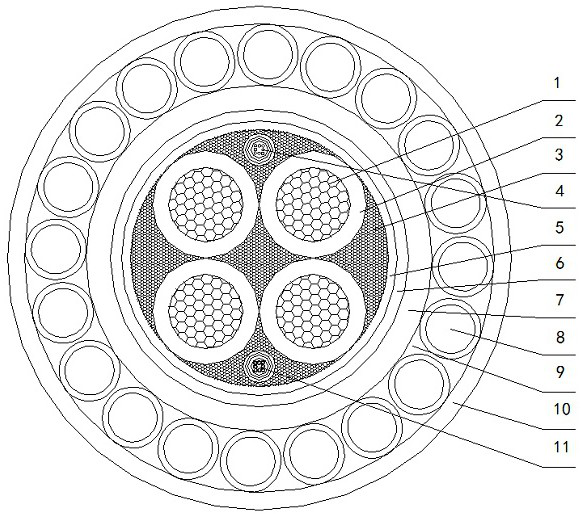

[0022] A dynamically adjustable multi-core optical fiber composite self-suspending cable, such as figure 1 , figure 2 As shown, the present embodiment includes several conductive cores coated with an insulating layer 2, and several conductive cores are coated and filled with tensile load-bearing elements 3 to form a main core, and the tensile load-bearing elements 3 in the main core are also arranged with The optical unit 4 and the control cable 11, the main core is coated with double-sided water-blocking tape 5 in turn, and the double-sided water-blocking tape 5 is longitudinally wrapped with aluminum-plastic composite tape 6 and extruded into a medium-density polyethylene waterproof sleeve 7, medium-density polyethylene Several elastic air tubes 8 are distributed along the circumference of the waterproof cover 7. Several elastic air tubes 8 are covered by an elastic outer sheath 10. One end of several elastic air tubes 8 is closed, and the other end is connected with the ai...

Embodiment 2

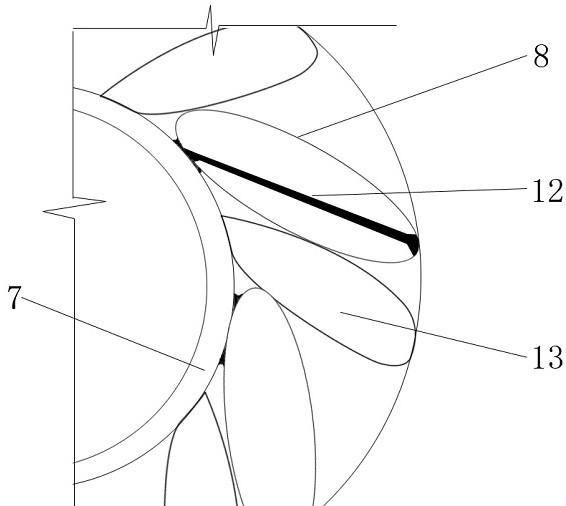

[0026] A dynamically adjustable multi-core optical fiber composite self-suspension cable. On the basis of the first embodiment, the structure of the elastic air tube 8 is further improved in this embodiment, which improves the adaptability of the composite self-suspension to large-span water depths. . Such as image 3 , Figure 4 As shown, in this embodiment, the elastic air tube 8 is provided with ribs 12, and the two ends of the ribs 12 are bonded to the inner wall of the elastic air tube 8, and the elastic air tube 8 and the medium density polyethylene waterproof sleeve 7 are in contact with the medium density polyethylene The waterproof cover 7 is bonded, and the rib 12 has an included angle with the radial direction of the main core when the elastic air tube 8 is filled with air. Between the elastic air tubes 8 are provided solid rubber rods 13, one end of the solid rubber rods 13 is bonded to the medium density polyethylene waterproof cover 7, and the other end is in c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com