Bullet train converter noise reduction design method based on reactive noise elimination

A technology of resistant noise reduction and design method, applied in the field of rail transit, can solve the problems of large radiated noise of converters, large low-frequency noise, exceeding noise control requirements, etc., achieve effective noise reduction cost, reduce cabinet noise, improve quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and examples, so as to fully understand and implement the process of how to apply technical means to solve technical problems and achieve technical effects in the present invention. It should be noted that, as long as there is no conflict, each embodiment and each feature in each embodiment of the present invention can be combined with each other, and the formed technical solutions are all within the protection scope of the present invention.

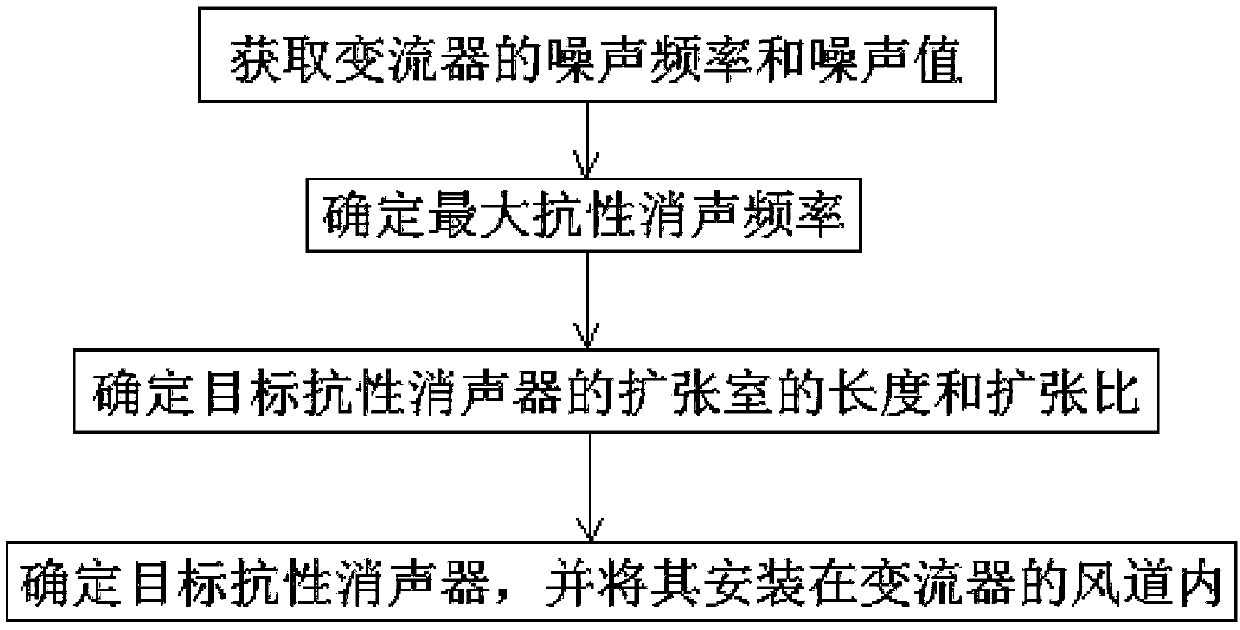

[0039] Such as Figure 1~3 As shown, the noise reduction design method of the motor train converter based on the resistance noise elimination proposed by the present invention includes:

[0040] 1) Obtain the noise frequency and noise value of the converter 1;

[0041] 2) Determine the frequency of maximum resistance muffler;

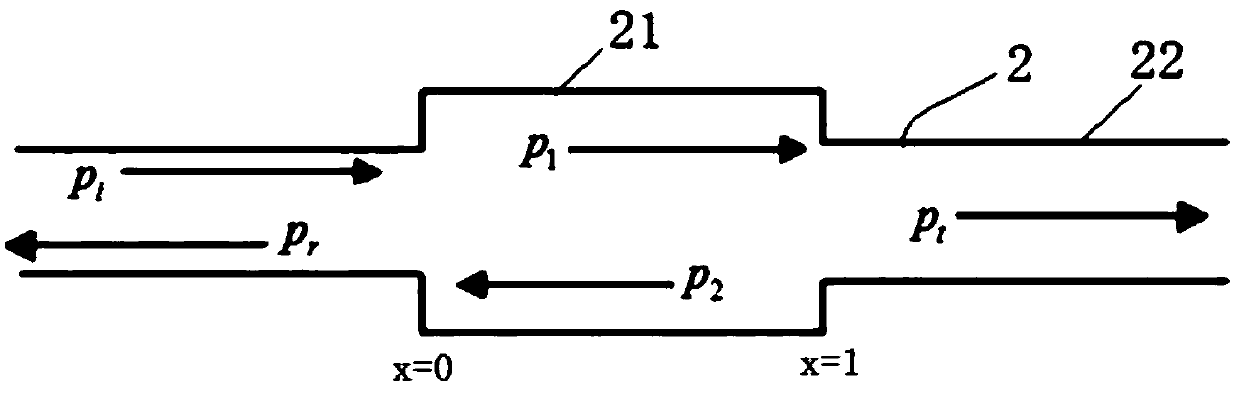

[0042] 3) Determine the length of the expansion chamber 21 of the target resist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com