Hardware debugging method of PCB

A PCB board and hardware debugging technology, which is applied in printed circuit testing, electronic circuit testing, etc., can solve problems such as system stability reduction, system complexity, and the inability to detect all PCB board hardware problems, so as to avoid resource consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

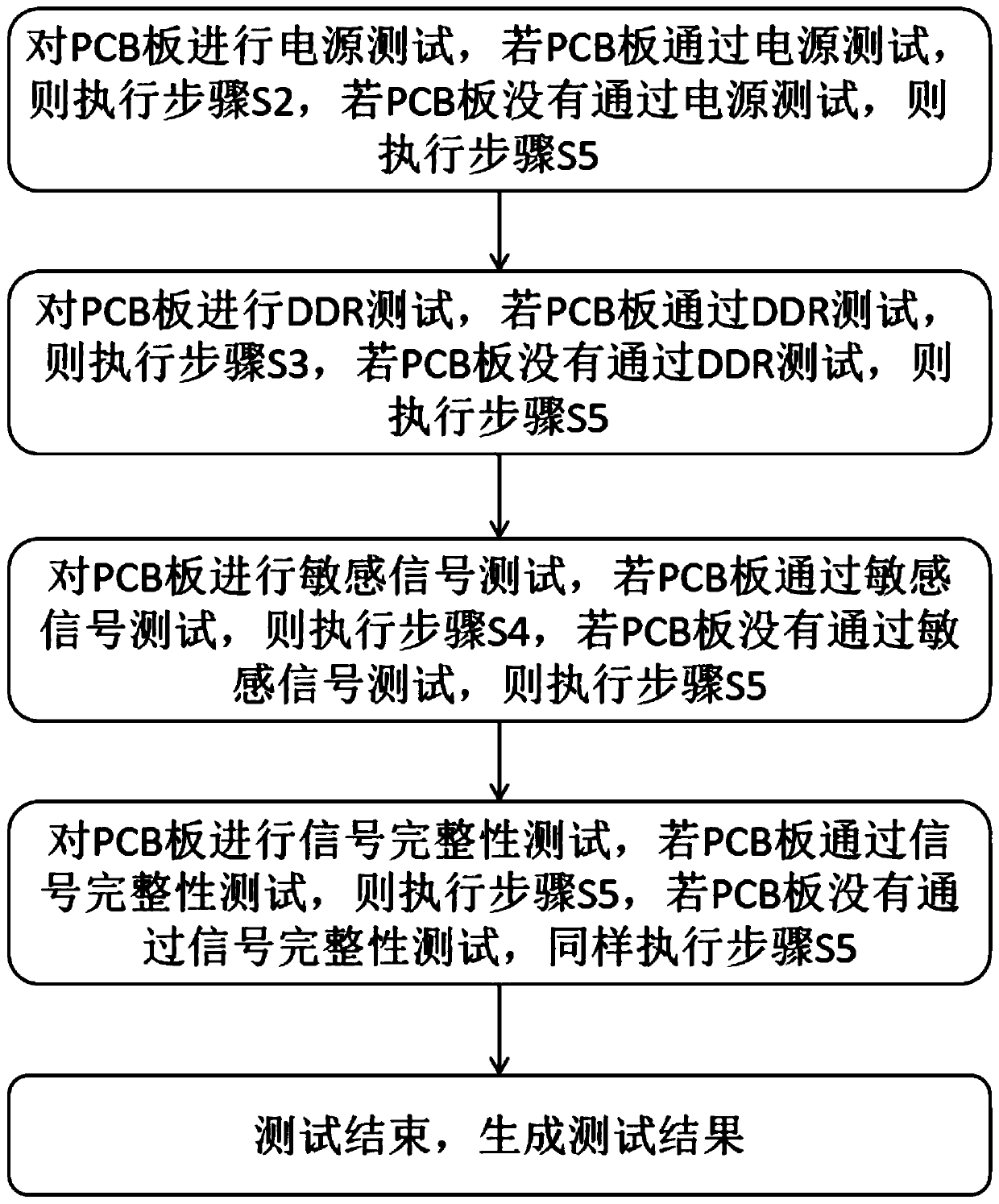

[0058] In order to describe the technical solution of the present invention more clearly and completely, the present invention will be further described below in conjunction with the accompanying drawings.

[0059] Please refer to figure 1 , the present invention proposes a kind of hardware debugging method of PCB board, the hardware debugging method of described PCB board comprises the steps:

[0060] S1: Perform a power test on the PCB board, if the PCB board passes the power test, then perform step S2, if the PCB board does not pass the power test, then perform step S5;

[0061] S2: Carry out DDR test on the PCB board, if the PCB board passes the DDR test, then execute step S3, if the PCB board does not pass the DDR test, then execute step S5;

[0062] S3: Perform a sensitive signal test on the PCB board, if the PCB board passes the sensitive signal test, then perform step S4, if the PCB board does not pass the sensitive signal test, then perform step S5;

[0063] S4: Car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com