Maximum correlation kurtosis deconvolution method without period

A maximum correlation and deconvolution technology, which is applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve problems such as keeping constant, difficult rotation of mechanical equipment, and prolonged time, so as to achieve less input parameters , No need for resampling operation, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

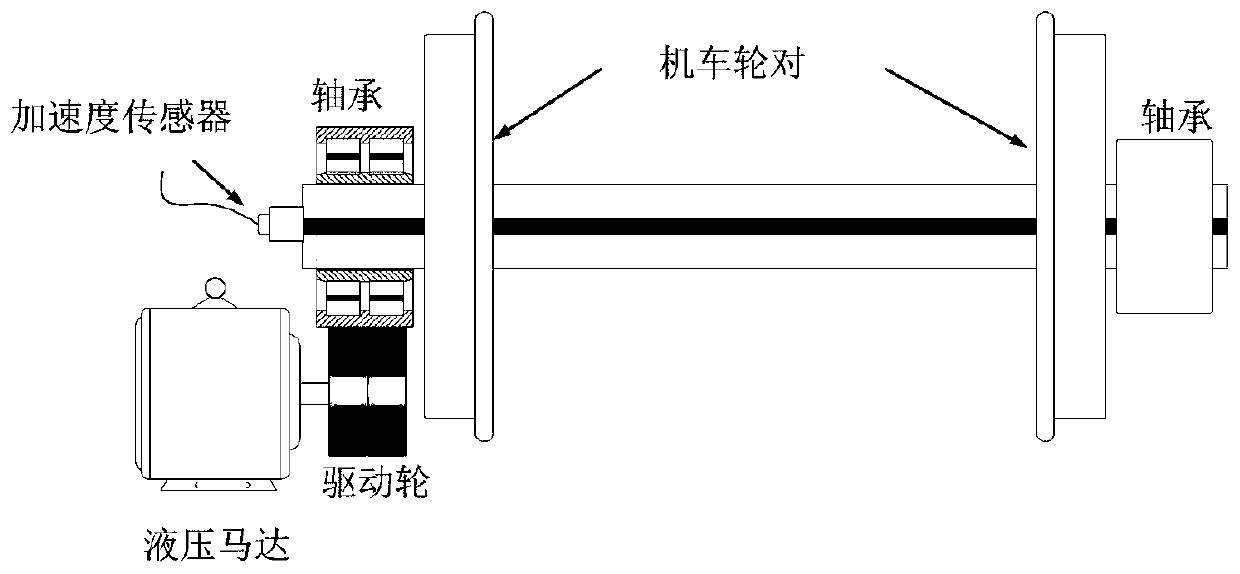

[0036] The embodiment adopts a certain locomotive bearing test bench, such as figure 1 As shown, the test bench is composed of hydraulic motor, driving wheel, bearing and locomotive wheel pair. The hydraulic motor drives the driving wheel to move and then drives the outer ring of the bearing to move. The inner ring of the bearing is fixed on the axle of the locomotive wheel set. The acceleration sensor is fixed on the At one end of the bearing, the vibration signal of the bearing is measured.

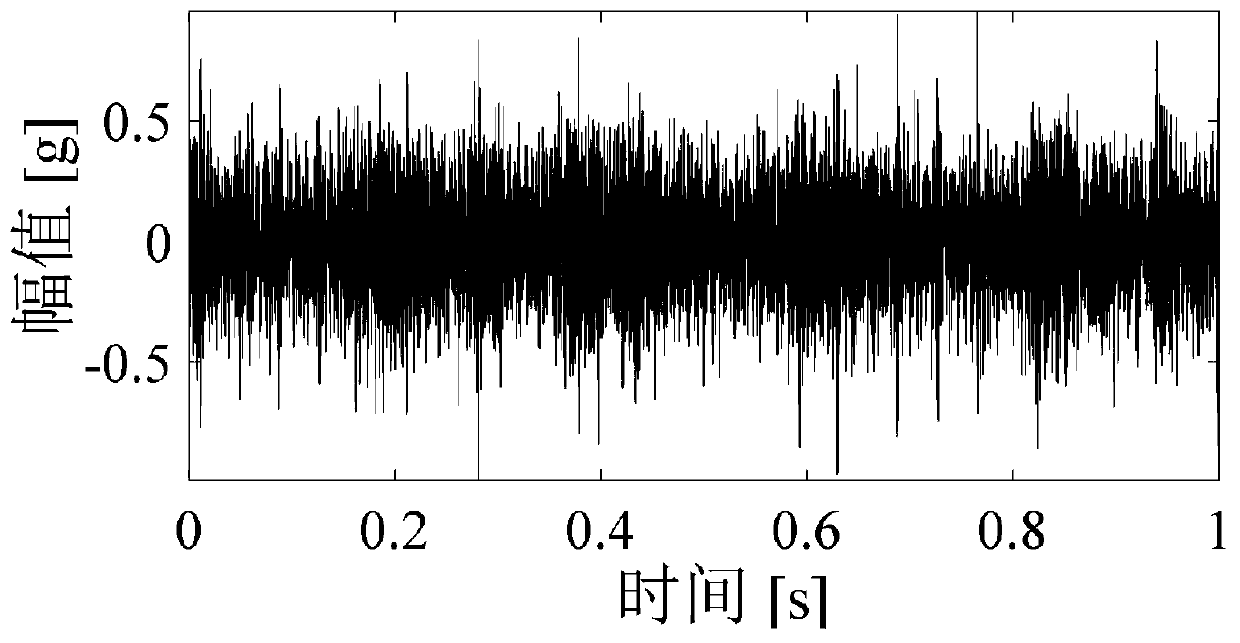

[0037] The wheel bearing in the test bench is diagnosed by using the maximum correlation kurtosis deconvolution method without period, and the experimental data are analyzed and compared with the traditional maximum correlation kurtosis deconvolution method.

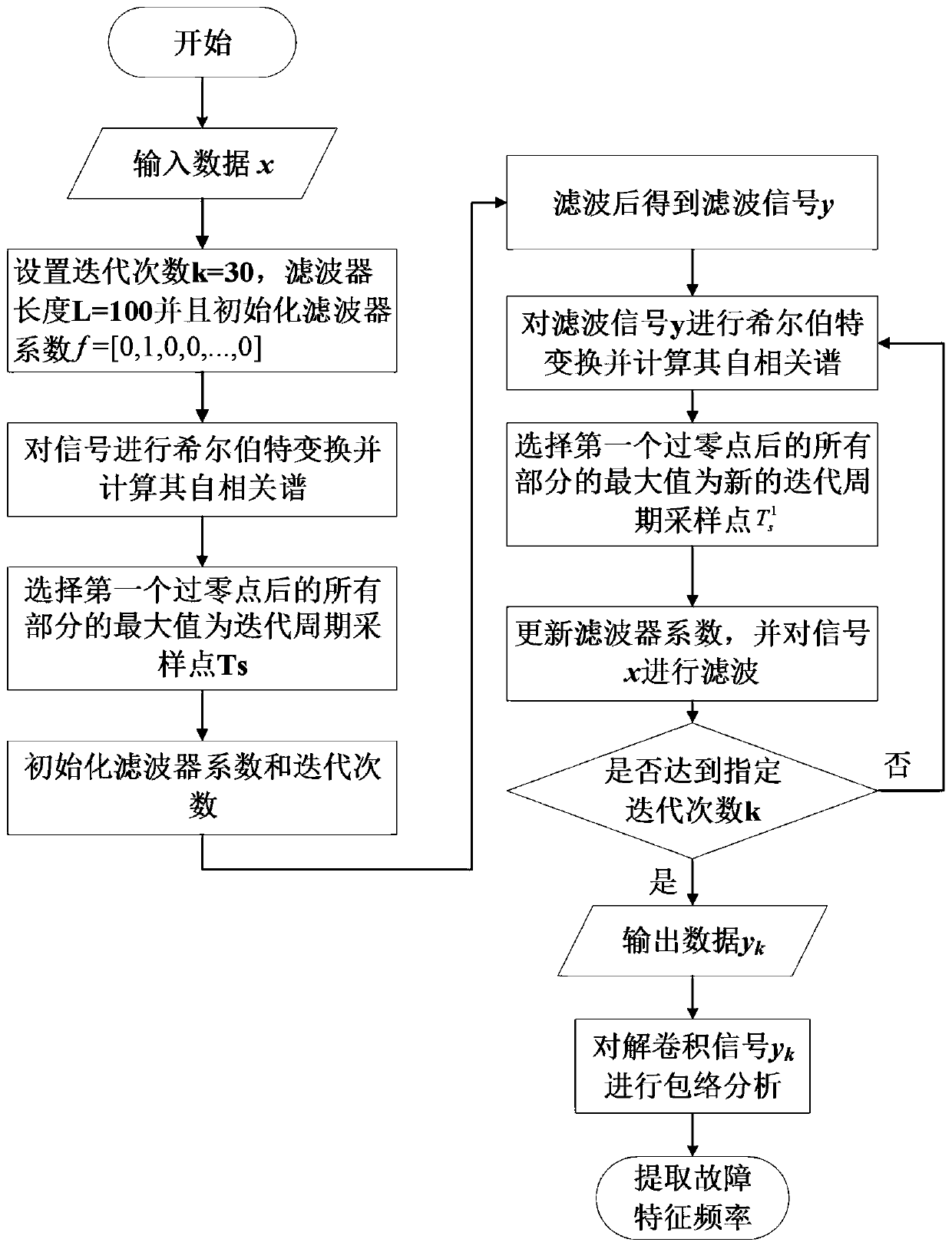

[0038] Such as figure 2 As shown, a cycle-free maximum correlation kurtosis deconvolution method in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com