Explosive vibration mixing process stimulus testing system

A test system and hybrid process technology, applied in measurement devices, instruments, etc., to achieve the effect of electrostatic voltage measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

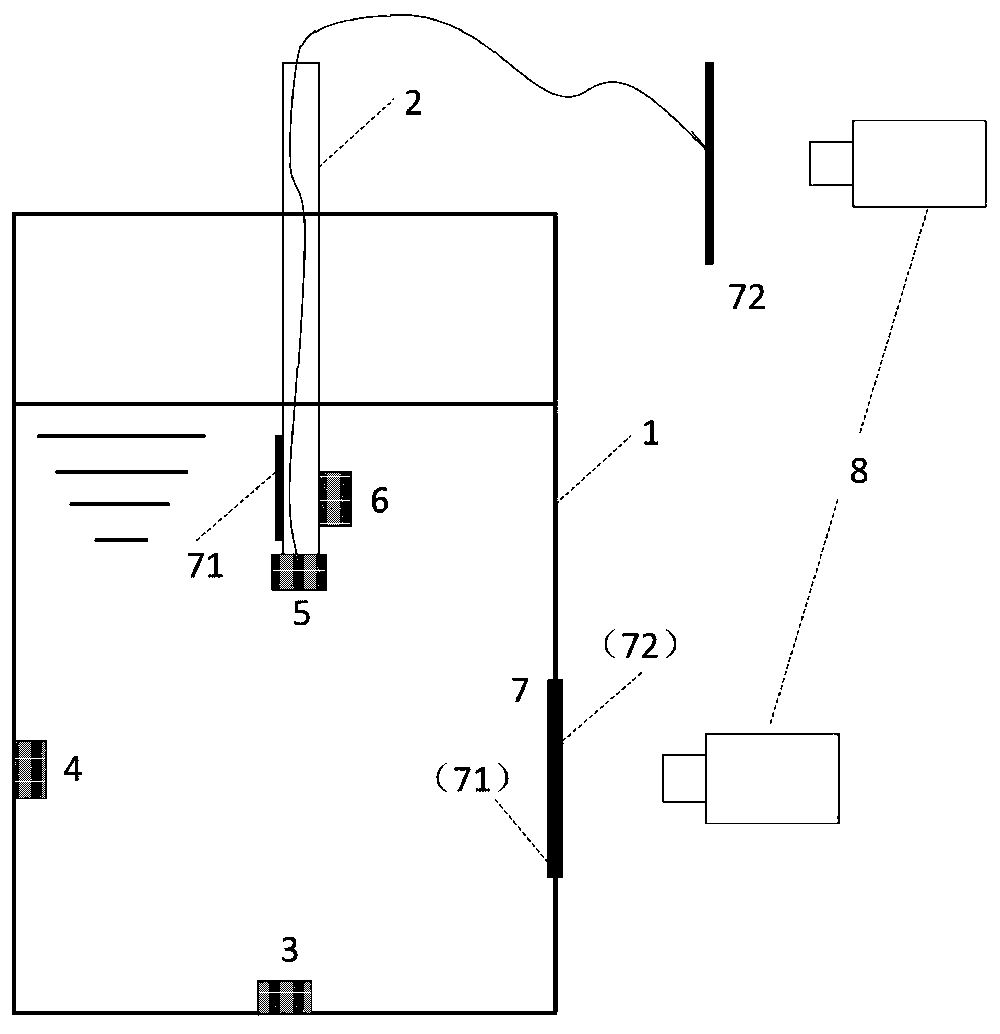

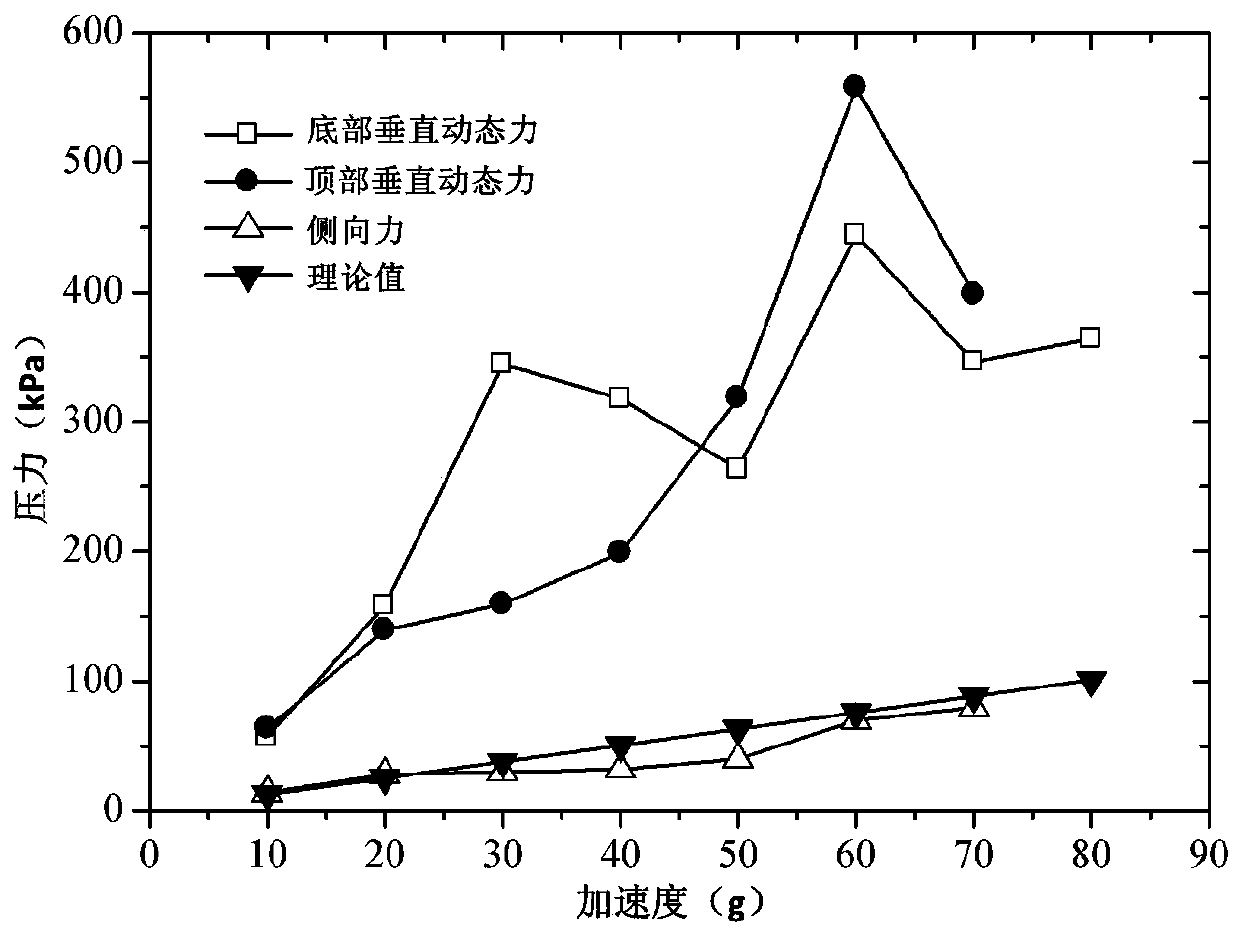

[0033] Put 2000 grams of PBX explosive simulant into the mixing vessel 1, the material of the mixing vessel 1 is stainless steel, the inner diameter is 110mm, and the height is 150mm. Using three stress sensors, respectively the first sensor 3, the third sensor 5 and the fourth sensor 6, the stress of the test is respectively the impact force of the mixed material on the bottom surface of the mixing container 1, the impact force of the mixed material on the top of the mixing container 1 (equivalent top ) impact force, inertial force inside the mixed material. Each stress is tested under the conditions of accelerations of 10g, 20g, 30g, 40g, 50g, 60g, 70g, and 80g, and the results are as follows figure 2 shown. From figure 2 It can be seen that the impact force of the mixed material on the bottom and top of the mixing container 1 is equal and increases with the acceleration; the inertial force inside the mixed material is consistent with the theoretical value calculated by ...

Embodiment 2

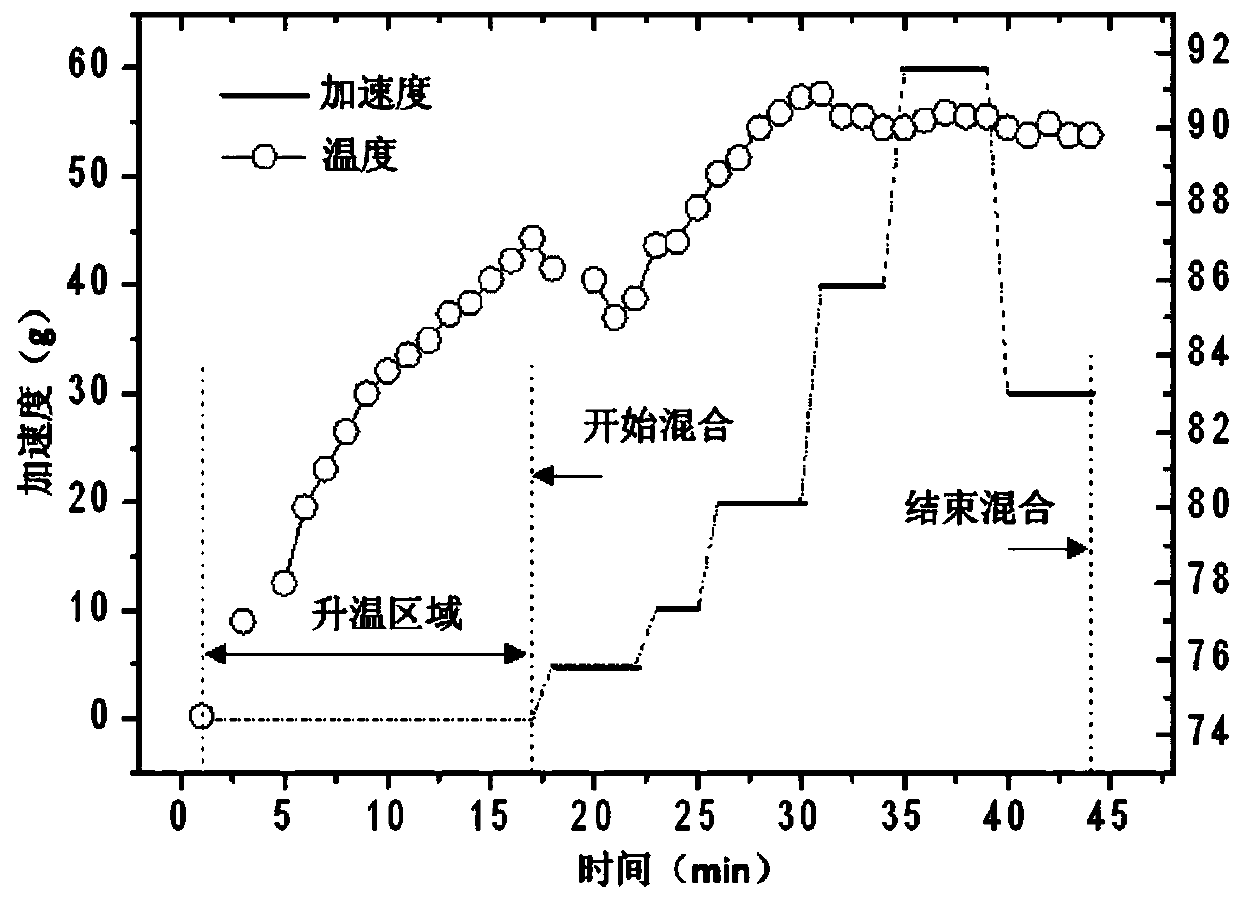

[0035] Put 2000 grams of PBX explosive simulant into the mixing vessel 1, the material of the mixing vessel 1 is stainless steel, the inner diameter is 110mm, and the height is 150mm. Install a thermocouple temperature sensor at the position of the second sensor 4, and test the temperature rise of the mixed material under the conditions of accelerations of 5g, 10g, 20g, 40g, 60g, and 30g, and the obtained data are as follows image 3 shown. From image 3 It can be seen that the temperature rise rate is not significantly affected by the acceleration, but is significantly affected by the mixing stage.

Embodiment 3

[0037] 1000 grams of sodium sulfate are packed into mixing container 1, and mixing container 1 material is plexiglass, and internal diameter is 110mm, and height is 150mm. Use the electrostatic isobaric surface 7 and the electrostatic voltage tester 8 to test the electrostatic voltage. Under the conditions of 10g, 20g, 30g, 50g, and 70g, the electrostatic voltage of the mixed material is tested, and the obtained data is as follows: Figure 4 shown. From Figure 4 It can be seen that the electrostatic voltage reaches a large value at the moment of mixing, and increases slightly as time increases. For the same material, the magnitude of the electrostatic voltage mainly depends on the magnitude of the acceleration, but is not greatly affected by the mixing time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com