A carbon dioxide gas cracking rock rod drilling equipment

A technology of carbon dioxide and rock cracking, applied in the direction of offensive equipment, earthwork drilling, blasting barrels, etc., can solve the problems of long consumption and low efficiency, and achieve the effect of saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

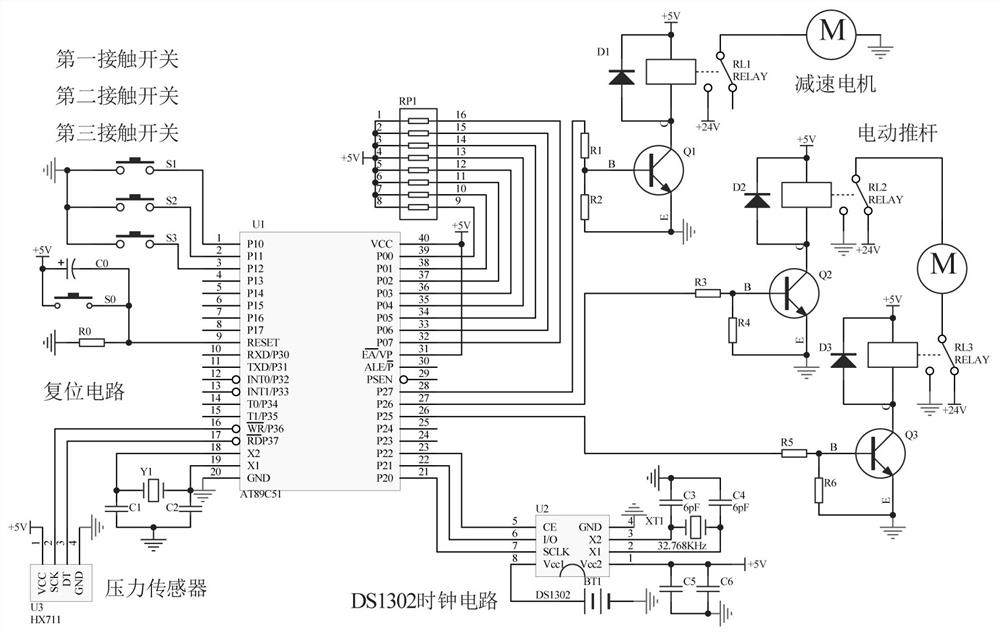

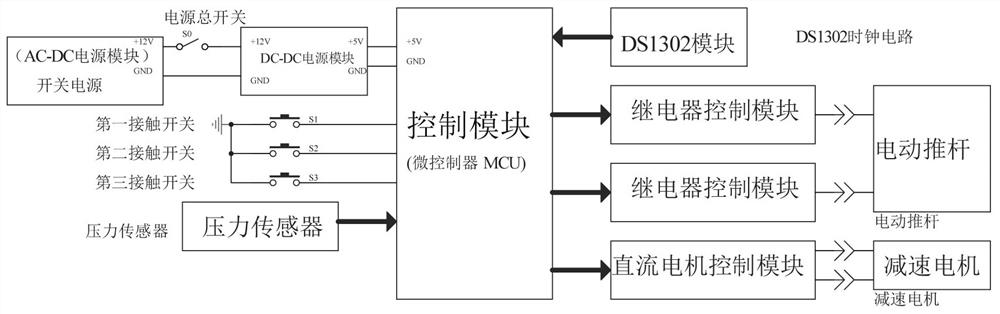

[0028] A carbon dioxide gas cracking rod into the hole equipment, such as Figure 1-3 As shown, it includes a fixed pipe 1, a lower casing 2, a locking assembly 3 and a deceleration mechanism 4. The bottom of the fixed pipe 1 is fixed with a lower casing 2, and a locking assembly 3 is arranged in the lower casing 2. The locking assembly 3 is used for The rock splitting rod is locked, the fixed pipe 1 is provided with a deceleration mechanism 4, and the deceleration mechanism 4 is used to reduce the moving speed of the rock splitting rod.

[0029] It also includes a control module, and both the locking assembly 3 and the deceleration mechanism 4 are wired to the control module.

[0030] The staff presses the main power switch, powers on the equipment, and then inserts the rock splitting rod into the lower casing 2. The rock splitting rod is pushed to the locking assembly 3, and the locking assembly 3 locks the rock splitting rod. The locking assembly 3 can also be used. Drive ...

Embodiment 2

[0032] On the basis of Example 1, as image 3 As shown, the locking assembly 3 includes an electric push rod 31 , a locking rod 32 , a first contact switch 33 , a second contact switch 34 and a pressure sensor 35 , and the electric push rod 31 , the first contact switch 33 are installed in the lower casing 2 And the pressure sensor 35, the first contact switch 33 is located between the electric push rod 31 and the pressure sensor 35, the push rod of the electric push rod 31 is fixed with a lock rod 32, and the left side of the lower housing 2 is installed with a second contact switch 34. The locking rod 32 is aligned with the second contact switch 34, the electric push rod 31 is connected with the control module through a peripheral circuit, and the first contact switch 33, the second contact switch 34 and the pressure sensor 35 are all wired to the control module.

[0033] When the equipment is powered on, the control module controls the pressure sensor 35 to work, the worker...

Embodiment 3

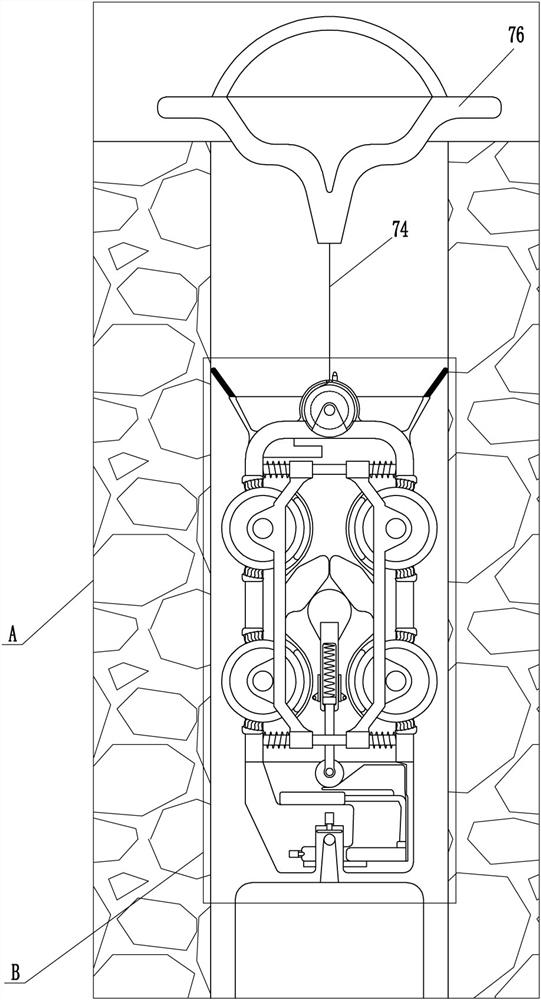

[0037] On the basis of Example 2, as Figure 2-6 As shown, a recovery assembly 7 is also included. The recovery assembly 7 includes a deceleration motor 71, a reel 72, a protection plate 73, a pull rope 74, a third contact switch 75 and a clamping ring 76. The top of the fixed tube 1 is installed with a deceleration The motor 71 and the protection plate 73, the deceleration motor 71 is located in the protection plate 73, the output shaft of the deceleration motor 71 is installed with a winding wheel 72, the winding wheel 72 is wound with a pull rope 74, and the pull rope 74 passes through the protection plate 73, A clamping ring 76 is connected to the pulling rope 74, a third contact switch 75 is arranged on the protection plate 73, the deceleration motor 71 is connected with the control module through a peripheral circuit, and the third contact switch 75 is connected with the control module by a circuit.

[0038] The worker puts the device into the pre-opened hole, puts the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com