Multifunctional integrated power tower

An integrated technology for power poles and towers, applied in the field of multifunctional integrated power poles and towers, which can solve problems such as breakage, easy toppling of power poles and towers, and threat of power poles and towers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

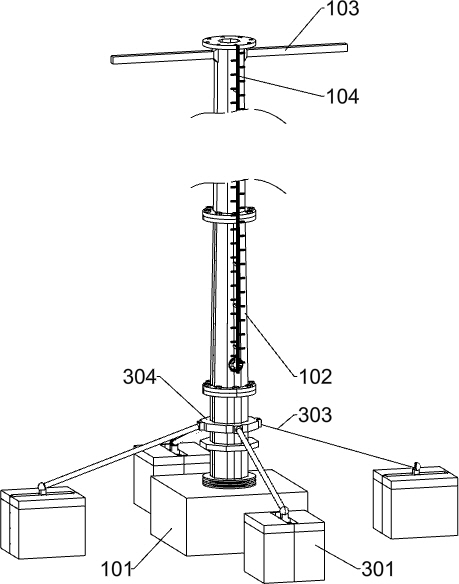

[0029] A multifunctional integrated power tower, such as Figure 1-Figure 9 As shown, a first base 101 is included, and rod bodies 102 are fixed on the first base 101. Several rod bodies 102 are provided and arranged vertically. Every two rod bodies 102 are fixedly connected by screws and nuts. The left and right sides of the inner upper part of the rod body 102 are provided with first limit holes 1021 for installation, and the left and right sides of the upper part of the uppermost rod body 102 are fixedly connected with a cable support frame 103. The cable support frame 103 is provided with overhead cables. A climbing frame 104 is fixedly connected to the front side of each rod body 102 through a connecting block. The climbing frame 104 is used to facilitate the operator to climb. The climbing frame 104 is provided with a first chute 1041 and the climbing frame 104 is There are several second limit holes 1042 for slowing down the operator's tendency to fall. The second limit...

Embodiment 2

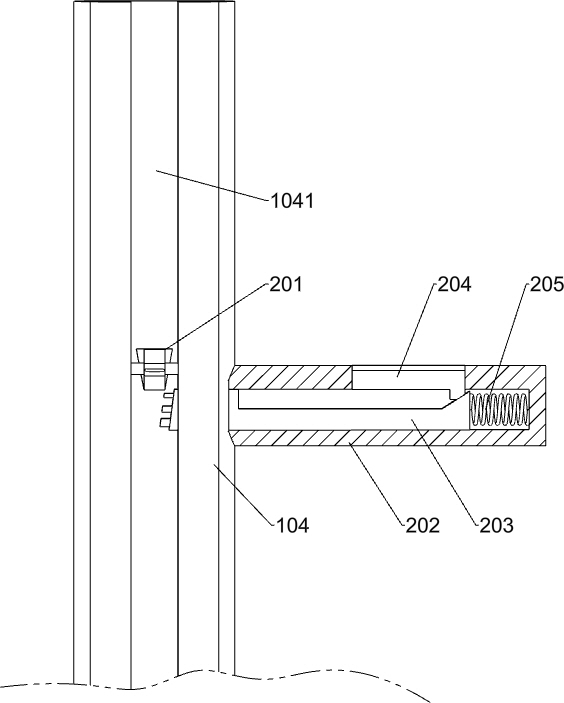

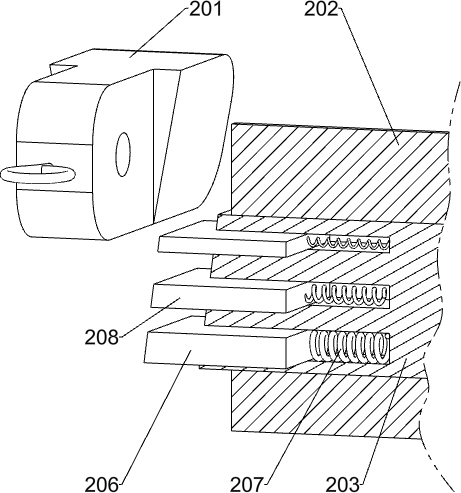

[0033] On the basis of Example 1, as Figure 1-Figure 5 As shown, the anti-fall mechanism includes an anti-fall sliding block 201, the anti-fall sliding block 201 is slidably connected to the climbing frame 104, the anti-fall sliding block 201 is located in the first chute 1041, and the left and right sides of the climbing frame 104 are fixedly connected There are several climbing foot frames 202, and the climbing foot frames 202 on both sides are staggered. The climbing foot frames 202 are slidably connected with a first sliding deceleration block 203 for slowing down the operator's falling speed. There are three chutes on the block 203, and a pedaling sliding block 204 is slidably connected to the climbing foot frame 202. Several pedaling sliding blocks 204 are squeezed and fitted with the adjacent first sliding deceleration blocks 203 respectively for preventing falling and sliding. The block 201 slides, and a first spring 205 is fixed between the several first sliding dece...

Embodiment 3

[0047] On the basis of Example 2, as Figure 6-Figure 8 As shown, the anti-tipping mechanism includes a second base 301, four second bases 301 are provided, and four second bases 301 are slidably connected with anti-dumping sliding blocks 302 for sensing the inclination angle of the rod body 102. Connecting rods 303 are spherically connected to each of the anti-overturning sliding blocks 302, and an octagonal fixing frame 304 is fixedly connected to the lowermost rod body 102. Two fifth springs 305 are fixed between the dumping sliding blocks 302 and the adjacent second bases 301 respectively, and the eight fifth springs 305 are used to decelerate the adjacent anti-dumping sliding blocks 302 and slow down the inclination of the rod body 102 . Angle, the second base 301 is slidably connected with an anti-dumping component, and the anti-dumping component is used to further decelerate the adjacent anti-dumping sliding blocks 302 .

[0048] The anti-overturning assembly includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com